Discover how to diagnose and interpret the check engine light on your 1994 Volvo 850 using basic tools and built-in diagnostic features. This guide walks you through reading trouble codes manually and understanding what they mean, even decades after the car was made.

Key Takeaways

- Manual code retrieval is possible: The 1994 Volvo 850 doesn’t require a scanner—you can read engine trouble codes using the dashboard and a paperclip or jumper wire.

- Locate the diagnostic port correctly: The OBD-I diagnostic connector is under the hood near the driver’s side firewall—knowing its exact location saves time.

- Understand flash patterns: The check engine light flashes in sequences that correspond to specific trouble codes—learning to count them is key.

- Common issues include oxygen sensors and ignition problems: Many 1994 Volvo 850 check engine lights are triggered by aging emissions or ignition components.

- Safety first when working under the hood: Always disconnect the battery before probing electrical connections to avoid short circuits.

- Document codes before clearing them: Write down all retrieved codes before resetting the system to track recurring issues.

- Use factory service manuals for accuracy: For complex repairs, refer to the original Volvo 850 service manual to avoid misdiagnosis.

How to Check Check Engine Light on 1994 Volvo 850

If you’re driving a classic 1994 Volvo 850 in 2026, you’re likely enjoying its timeless design, solid build quality, and smooth ride. But like any aging vehicle, it can develop issues—and one of the first signs is often the dreaded check engine light. Unlike modern cars with advanced onboard diagnostics, the 1994 Volvo 850 uses an older OBD-I (On-Board Diagnostics Generation I) system. That means no Bluetooth scanners or smartphone apps. But don’t worry—you can still read the trouble codes yourself with just a paperclip and a bit of patience.

In this guide, you’ll learn exactly how to check the check engine light on your 1994 Volvo 850. We’ll walk you through locating the diagnostic port, retrieving trouble codes manually, interpreting the flash patterns, and understanding what those codes mean. Whether you’re a DIY enthusiast or just want to avoid unnecessary mechanic visits, this step-by-step tutorial will give you the confidence to diagnose your Volvo like a pro.

Why the Check Engine Light Comes On

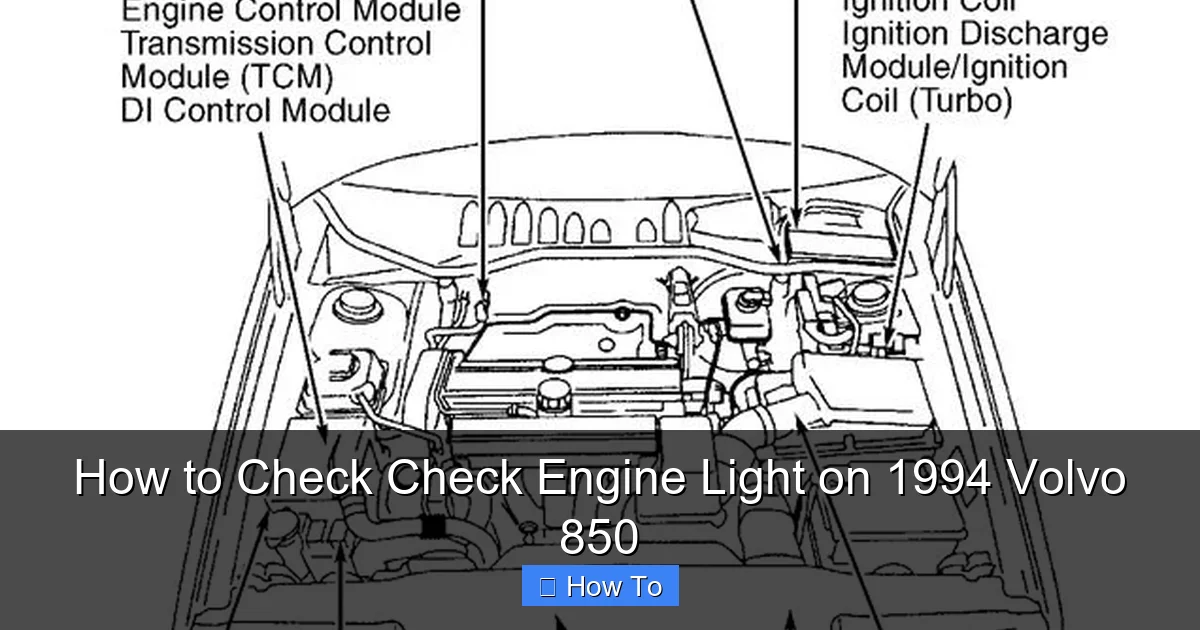

Visual guide about How to Check Check Engine Light on 1994 Volvo 850

Image source: engineworld.com

Before diving into the how-to, it’s helpful to understand why the check engine light might illuminate in the first place. The 1994 Volvo 850’s engine control module (ECM) monitors various sensors and systems, including the oxygen sensor, mass airflow sensor, ignition system, and emissions controls. When something goes outside normal parameters—like a misfire, faulty sensor, or vacuum leak—the ECM triggers the check engine light to alert you.

Common causes in 1994 Volvo 850 models include:

– Failing oxygen (O2) sensors

– Worn spark plugs or ignition coils

– Loose or damaged vacuum hoses

– Faulty mass airflow (MAF) sensor

– Exhaust gas recirculation (EGR) valve issues

– Fuel system problems (e.g., fuel pressure regulator)

Because the 850 is now over 30 years old, wear and tear on these components is expected. Rubber hoses dry out, sensors degrade, and electrical connections corrode. The good news? Many of these issues are fixable with basic tools and some know-how.

Tools You’ll Need

The beauty of the 1994 Volvo 850’s diagnostic system is that it doesn’t require expensive equipment. Here’s what you’ll need:

- A paperclip or small jumper wire (preferably with insulated ends)

- A flashlight (for better visibility under the hood)

- A notepad and pen (to record trouble codes)

- Basic hand tools (screwdriver, socket set—optional for further inspection)

- Your vehicle’s owner’s manual or service manual (for reference)

You won’t need an OBD-II scanner—this model predates that standard. Instead, you’ll use the car’s built-in self-diagnostic mode to retrieve codes via the dashboard light.

Step 1: Locate the Diagnostic Connector

The first step in checking the check engine light is finding the diagnostic port. On the 1994 Volvo 850, this is an OBD-I style connector located under the hood—not inside the cabin like newer cars.

Where to Look

Open the hood and look on the driver’s side, near the firewall (the wall between the engine compartment and the cabin). You’re looking for a small, rectangular plastic connector with two rows of pins—usually 6 pins total, arranged in two rows of three.

It’s often tucked behind a plastic cover or near the brake fluid reservoir. If you’re having trouble finding it, consult your owner’s manual or look for a label that says “DIAG” or “ECM.”

Identify the Correct Pins

Once you’ve found the connector, you’ll notice it has six pins labeled A through F. For code retrieval, you only need to focus on two:

– Pin A (ground)

– Pin B (diagnostic signal)

These are typically the two pins on the outer edges of the connector. Pin A is usually on the far left, and Pin B is on the far right when facing the connector.

Step 2: Prepare the Jumper Wire

Now that you’ve located the diagnostic port, it’s time to create a simple jumper to trigger the code readout.

Create the Jumper

Straighten out a paperclip or use a short piece of insulated wire with stripped ends. You’ll use this to connect Pin A (ground) to Pin B (diagnostic signal). This connection tells the ECM to enter diagnostic mode and start flashing the trouble codes through the check engine light.

Safety Tip

Before inserting the jumper, make sure the ignition is off and the key is removed. This prevents accidental shorts or damage to the ECM. Also, avoid touching any metal parts of the paperclip to other electrical components while probing.

Step 3: Enter Diagnostic Mode

With the jumper ready, it’s time to activate the self-diagnostic system.

Insert the Jumper

Carefully insert one end of the paperclip into Pin A and the other into Pin B. Make sure the connection is secure—loose contact can cause inconsistent readings.

Turn the Ignition On

With the jumper in place, turn the ignition key to the “ON” position (but do not start the engine). You should see the dashboard lights illuminate, including the check engine light.

Watch for Flash Patterns

Within a few seconds, the check engine light will begin to flash. These flashes represent trouble codes in a series of long and short pulses. Each code is displayed as a two-digit number:

– A long flash = tens digit

– A short flash = ones digit

For example, two long flashes followed by three short flashes means Code 23.

Step 4: Read and Record the Trouble Codes

Now comes the most important part: interpreting the flash sequence.

Count the Flashes Carefully

Watch the check engine light closely. The flashes will repeat in cycles. Each code is separated by a brief pause, and the entire sequence may repeat multiple times.

Write down each code as it appears. For example:

– Long, long, short, short, short = 23

– Long, short, short = 12

– Short, short, short, short = 04

Some codes may appear more than once—this indicates they are active or recurring issues.

Example: Reading Code 13

Let’s say you see one long flash, followed by three short flashes. That’s Code 13. According to Volvo’s 1994 850 service manual, Code 13 typically indicates a problem with the engine coolant temperature (ECT) sensor or its circuit.

Wait for All Codes

The system will cycle through all stored trouble codes. Be patient—some codes may take a few seconds to appear. Once the sequence repeats from the beginning, you’ve seen all active codes.

Step 5: Interpret the Trouble Codes

Now that you’ve recorded the codes, it’s time to understand what they mean. The 1994 Volvo 850 uses a specific set of diagnostic trouble codes (DTCs) that differ slightly from modern OBD-II standards.

Here are some common codes and their meanings:

- Code 11: Mass Airflow (MAF) sensor circuit malfunction

- Code 12: Throttle Position Sensor (TPS) issue

- Code 13: Engine Coolant Temperature (ECT) sensor problem

- Code 14: Intake Air Temperature (IAT) sensor fault

- Code 21: Oxygen (O2) sensor circuit malfunction (front)

- Code 22: Oxygen (O2) sensor circuit malfunction (rear)

- Code 23: EGR system malfunction

- Code 31: Ignition coil or spark plug issue

- Code 32: Fuel injector circuit problem

- Code 41: Vehicle Speed Sensor (VSS) fault

For a complete list, refer to the official Volvo 850 service manual or a trusted repair database. Many online forums and Volvo enthusiast sites also maintain updated code charts.

Step 6: Troubleshoot Based on the Code

Once you know the code, you can begin diagnosing the root cause.

Example: Code 21 (O2 Sensor)

If you get Code 21, the front oxygen sensor is likely failing. This sensor monitors exhaust gases to help the ECM adjust the air-fuel mixture. A faulty O2 sensor can cause poor fuel economy, rough idling, or increased emissions.

Steps to Diagnose:

- Locate the front O2 sensor (usually on the exhaust manifold).

- Inspect the wiring for damage, corrosion, or loose connections.

- Use a multimeter to test the sensor’s voltage output (should fluctuate between 0.1 and 0.9 volts).

- If the sensor is unresponsive or stuck, replace it.

Example: Code 31 (Ignition Coil)

Code 31 often points to a weak or failing ignition coil. The 1994 Volvo 850 uses a distributorless ignition system (DIS), so each coil fires two cylinders.

Steps to Diagnose:

- Check for spark at the spark plugs using a spark tester.

- Swap coils between cylinders to see if the misfire follows the coil.

- Inspect coil connectors for corrosion or looseness.

- Replace the coil if necessary.

Step 7: Clear the Codes (Optional)

After diagnosing and fixing the issue, you may want to clear the trouble codes to turn off the check engine light.

Method 1: Disconnect the Battery

The simplest way to reset the ECM is to disconnect the negative terminal of the battery for at least 10 minutes. This cuts power to the ECM and clears stored codes.

Method 2: Use the Jumper Again

Some Volvo 850 models allow you to clear codes by reinserting the jumper after repairs and cycling the ignition. However, this method is less reliable than a battery disconnect.

Important Note

Clearing codes doesn’t fix the underlying problem. If the issue persists, the light will come back on. Always verify repairs before resetting.

Troubleshooting Tips and Common Pitfalls

Even with the right steps, things can go wrong. Here are some common issues and how to avoid them.

Check Engine Light Doesn’t Flash

If the light doesn’t flash when you insert the jumper:

– Double-check the pin connections (A to B).

– Ensure the ignition is on.

– Verify the light bulb isn’t burnt out.

– Try wiggling the jumper slightly—sometimes contact is poor.

Inconsistent or Missing Codes

If codes appear incomplete or skip:

– The ECM may have intermittent faults.

– Corrosion in the diagnostic port can disrupt signals—clean the pins with electrical contact cleaner.

– The battery voltage may be low—ensure it’s above 12 volts.

False Codes Due to Age

Older Volvos often throw false codes due to degraded sensors or wiring. For example, a weak battery can cause voltage-related codes even if the sensor is fine. Always check the basics first: battery, alternator, and ground connections.

Safety Reminder

Never work on the electrical system with wet hands or in damp conditions. Always disconnect the battery before probing circuits to prevent short circuits or personal injury.

When to Seek Professional Help

While many issues can be resolved at home, some problems require specialized tools or expertise.

Consider visiting a mechanic if:

– Multiple codes appear and point to complex systems (e.g., transmission or ABS).

– You suspect internal engine damage (e.g., low compression).

– The check engine light flashes while driving (indicating a severe misfire that can damage the catalytic converter).

– You’re unable to locate or interpret the codes after multiple attempts.

A certified Volvo specialist will have access to factory diagnostic tools and service bulletins that can save you time and money.

Maintaining Your 1994 Volvo 850 in 2026

Keeping your classic Volvo running smoothly requires regular maintenance. Here are a few tips to prevent future check engine light issues:

- Replace sensors proactively: O2 sensors and MAF sensors degrade over time—consider replacing them every 100,000 miles.

- Inspect vacuum hoses: Cracked or brittle hoses are a common cause of lean codes—replace them with silicone hoses for longevity.

- Use quality fuel and oil: Clean combustion reduces sensor fouling and extends engine life.

- Check grounds and connections: Corroded ground straps can cause erratic ECM behavior—clean and tighten them regularly.

- Keep a repair log: Document all codes, repairs, and parts replaced to track patterns over time.

Conclusion

Checking the check engine light on a 1994 Volvo 850 might seem daunting at first, but with the right approach, it’s entirely doable. By using a simple paperclip to access the OBD-I system, you can retrieve trouble codes, diagnose common issues, and take control of your car’s maintenance. Whether you’re dealing with a faulty oxygen sensor, ignition problem, or vacuum leak, this guide gives you the tools to understand what’s happening under the hood.

Remember, the key is patience and attention to detail. Count the flashes carefully, record the codes, and consult reliable resources before making repairs. And while the 1994 Volvo 850 may be a classic, it still has plenty of life left—especially when you treat it with care.

So the next time that check engine light comes on, don’t panic. Grab a paperclip, follow these steps, and drive on with confidence.