Discover how to read the check engine light on your 1992 Nissan 300ZX using basic tools and no OBD2 scanner. This guide walks you through retrieving diagnostic trouble codes (DTCs) manually, interpreting them, and taking the right next steps—perfect for classic car owners in 2026.

Key Takeaways

- Manual code retrieval is possible: Unlike modern cars, the 1992 Nissan 300ZX uses an OBD1 system, allowing you to read engine codes without a scanner by grounding a service connector.

- Understanding flash patterns is key: The check engine light blinks in sequences that represent two-digit trouble codes—count the long and short flashes to decode the issue.

- Common issues include O2 sensors and ignition problems: Many 1992 300ZX models trigger the light due to aging oxygen sensors, faulty knock sensors, or distributor issues.

- Always reset the ECU after repairs: Clearing codes ensures the system recognizes the fix and prevents false warnings.

- Use a multimeter for deeper diagnostics: After retrieving codes, test sensors and circuits to confirm the root cause before replacing parts.

- Document your findings: Keep a log of codes and repairs to track recurring issues and improve long-term maintenance.

- Seek professional help if needed: Some electrical faults require advanced tools—don’t hesitate to consult a mechanic familiar with early 90s Nissans.

How to Check Engine Light 1992 Nissan 300ZX: A Complete DIY Guide for 2026

If you’re driving a classic 1992 Nissan 300ZX and the check engine light suddenly flashes on, don’t panic—this guide will help you understand what’s happening under the hood. Unlike modern vehicles with OBD2 systems and universal scanners, the 1992 300ZX uses an older OBD1 diagnostic system. That means no plug-and-play code readers. But the good news? You can still read the trouble codes yourself using simple tools and a bit of patience.

In this comprehensive how-to guide, you’ll learn exactly how to check the engine light on your 1992 Nissan 300ZX. We’ll walk you through locating the diagnostic port, grounding the correct terminal, reading the flashing light patterns, interpreting the codes, and taking action based on what you find. Whether you’re a seasoned DIYer or a first-time classic car owner, this step-by-step process will empower you to diagnose issues confidently—no expensive tools required.

By the end of this guide, you’ll know how to retrieve and understand diagnostic trouble codes (DTCs), troubleshoot common problems, and even reset the engine control unit (ECU). Plus, we’ll share pro tips for maintaining your 300ZX’s engine health in 2026 and beyond. Let’s get started.

Why the Check Engine Light Comes On in a 1992 Nissan 300ZX

Before diving into the how-to, it’s important to understand why the check engine light might illuminate in your 1992 Nissan 300ZX. This light—also known as the Malfunction Indicator Lamp (MIL)—is triggered when the engine control unit (ECU) detects a problem with the engine, emissions, or fuel system.

Common causes include:

– Faulty oxygen (O2) sensors

– Malfunctioning knock sensors

– Ignition system issues (e.g., distributor, coil, or spark plugs)

– Vacuum leaks

– Fuel delivery problems (fuel pump, injectors)

– Exhaust gas recirculation (EGR) valve failure

– Coolant temperature sensor errors

Because the 300ZX is now over 30 years old, many of its original components are nearing or past their expected lifespan. Rubber hoses degrade, sensors drift out of calibration, and electrical connections corrode. Regular maintenance and early diagnosis can prevent minor issues from becoming major repairs.

Tools You’ll Need

You don’t need a fancy OBD2 scanner for a 1992 Nissan 300ZX. Here’s what you’ll need to check the engine light manually:

- A small piece of wire (paperclip or jumper wire works)

- A flashlight (for visibility under the dash)

- A notepad and pen (to record flash patterns)

- A multimeter (optional, for advanced diagnostics)

- Basic hand tools (screwdriver, socket set—if removing panels)

All of these items are inexpensive and widely available. The wire is used to ground a specific terminal in the diagnostic connector, which tells the ECU to output trouble codes via the check engine light.

Step 1: Locate the Diagnostic Service Connector

The first step in checking the engine light is finding the diagnostic service connector. In the 1992 Nissan 300ZX, this connector is located under the dashboard on the driver’s side, near the steering column.

Finding the Connector

Sit in the driver’s seat and look up under the dashboard. You’re looking for a small, rectangular plastic connector with multiple pins—usually black or gray. It’s often tucked behind the lower dash panel or near the fuse box. If you can’t see it immediately, use your flashlight to scan the area.

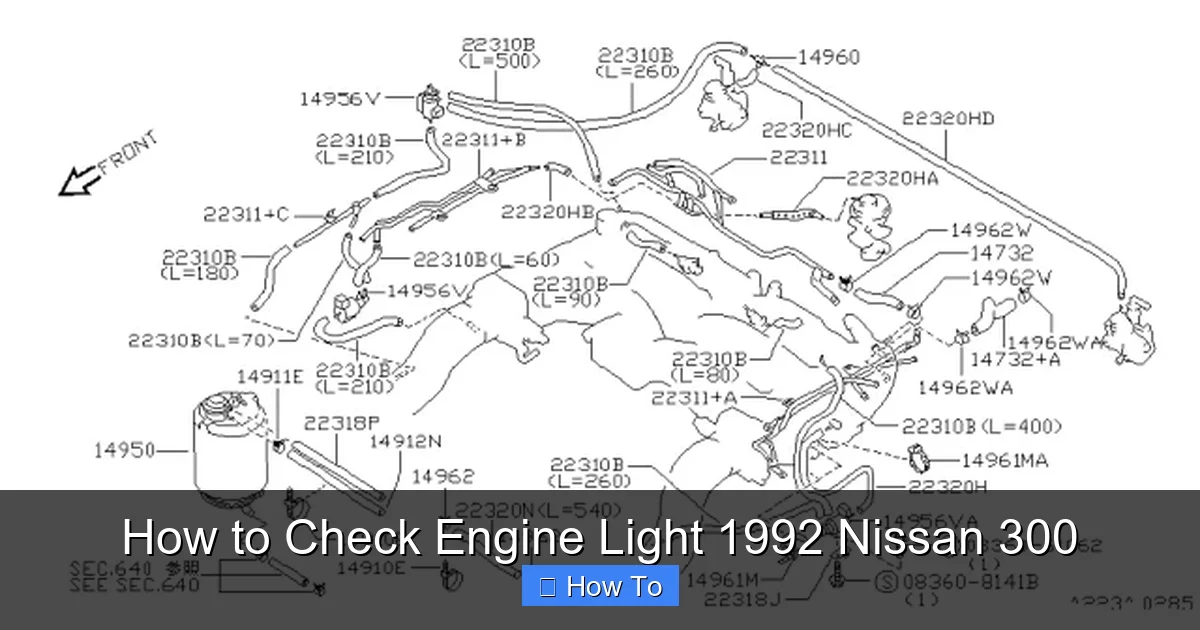

Visual guide about How to Check Engine Light 1992 Nissan 300

Image source: youcanic.com

Identifying the Correct Pins

The service connector has several pins, but you only need to focus on two: the “TEN” (Test Engine) terminal and the “GND” (Ground) terminal. These are typically labeled on the connector housing or nearby. If they’re not labeled, refer to a 1992 300ZX service manual or online diagram—many classic car forums have accurate pinouts.

Tip: Use a Diagram

If you’re unsure, search for “1992 Nissan 300ZX OBD1 diagnostic connector pinout” online. Screenshots from forums like ZCarClub or NissanZ forums are especially helpful. Save one to your phone for quick reference.

Step 2: Ground the TEN Terminal

Once you’ve located the service connector, it’s time to ground the TEN terminal. This tells the ECU to enter diagnostic mode and start outputting trouble codes.

Prepare the Jumper Wire

Straighten a paperclip or use a short piece of insulated wire with exposed ends. Strip about 1/4 inch of insulation from both ends if using wire.

Connect the Wire

Insert one end of the wire into the TEN terminal and the other end into the GND terminal. Make sure the connection is secure—loose contact can cause inaccurate readings.

Safety Note

Do not start the engine while the wire is connected unless instructed. Grounding the TEN terminal is only for reading codes with the ignition on (engine off).

Step 3: Turn the Ignition to “ON” (Do Not Start the Engine)

With the jumper wire in place, turn the key to the “ON” position. You should see dashboard lights illuminate, including the check engine light. The engine should remain off—this is crucial.

Watch the Check Engine Light

The check engine light will begin to flash in a specific pattern. These flashes represent diagnostic trouble codes (DTCs). Each code is a two-digit number, displayed as a series of long and short flashes.

Example: Code 12

A long flash (representing “1”) followed by two short flashes (representing “2”) means code 12. A long flash lasts about 1.5 seconds; a short flash lasts about 0.5 seconds. There’s a pause between digits and a longer pause between codes.

Record the Pattern

Use your notepad to write down the sequence. For example: “Long flash, pause, short-short, long pause” = Code 12. If multiple codes appear, the ECU will cycle through them repeatedly.

Step 4: Interpret the Trouble Codes

Now that you’ve recorded the flash pattern, it’s time to decode it. The 1992 Nissan 300ZX uses a standard set of OBD1 codes. Here are the most common ones:

- Code 11: Crankshaft position sensor (CKP) malfunction

- Code 12: Mass airflow (MAF) sensor or circuit issue

- Code 13: Engine coolant temperature (ECT) sensor out of range

- Code 14: Throttle position sensor (TPS) signal abnormal

- Code 21: Oxygen (O2) sensor circuit malfunction

- Code 22: Knock sensor (KS) no signal

- Code 23: Vehicle speed sensor (VSS) malfunction

- Code 31: EGR system malfunction

- Code 34: Ignition coil or distributor issue

- Code 43: Fuel pump circuit problem

What If No Codes Appear?

If the check engine light stays solid or doesn’t flash, it could mean:

– There are no stored trouble codes (the light may be on for another reason)

– The ECU isn’t responding (possible ECU failure or wiring issue)

– The light itself is faulty

In this case, try re-grounding the TEN terminal or check the bulb. If the light still doesn’t flash, consider testing the ECU or consulting a mechanic.

Step 5: Troubleshoot Based on the Code

Once you’ve identified the code, it’s time to investigate the root cause. Here’s how to approach common issues:

Code 21: O2 Sensor Malfunction

The oxygen sensor monitors exhaust gases and helps the ECU adjust the air-fuel mixture. A faulty O2 sensor is one of the most common causes of the check engine light in older Nissans.

What to do: Locate the O2 sensor (usually in the exhaust manifold or downpipe). Check for corrosion, damage, or loose wiring. Use a multimeter to test resistance—refer to your service manual for specs. Replace if out of range.

Code 22: Knock Sensor No Signal

The knock sensor detects engine knocking and adjusts ignition timing. A failed sensor can cause poor performance and reduced fuel economy.

What to do: The knock sensor is typically mounted on the engine block. Inspect the wiring harness for damage. Test the sensor’s resistance with a multimeter. Replace if faulty.

Code 34: Ignition Coil or Distributor Issue

The 300ZX uses a distributor-based ignition system. Over time, the distributor cap, rotor, or coil can wear out.

What to do: Remove the distributor cap and inspect for carbon tracking, cracks, or moisture. Test the coil’s primary and secondary resistance. Replace worn components.

Code 12: MAF Sensor Problem

The mass airflow sensor measures how much air enters the engine. A dirty or faulty MAF can cause rough idle and poor acceleration.

What to do: Clean the MAF sensor with MAF-specific cleaner (do not use carb cleaner). If cleaning doesn’t help, test the sensor’s output voltage with a multimeter. Replace if necessary.

Step 6: Clear the Codes and Reset the ECU

After diagnosing and fixing the issue, you’ll want to clear the trouble codes and reset the ECU to ensure the check engine light turns off.

Method 1: Disconnect the Battery

The simplest way to reset the ECU is to disconnect the negative battery terminal for at least 10 minutes. This cuts power to the ECU and clears stored codes.

Tip: Before disconnecting, note your radio code (if equipped) and any saved settings. Reconnect the battery and turn the ignition to “ON” to see if the light remains off.

Method 2: Use the Service Connector

Some 300ZX models allow you to clear codes by grounding the “CONSULT” terminal (if present) after repairs. Check your service manual for this option.

Verify the Fix

After resetting, drive the car for a few miles. If the check engine light returns, the problem may not be fully resolved—or a new issue has emerged.

Advanced Diagnostics: Using a Multimeter

For deeper troubleshooting, a multimeter is invaluable. Here’s how to use it on common sensors:

Testing the O2 Sensor

Set the multimeter to DC voltage. Back-probe the O2 sensor signal wire (usually black or white) with the positive lead and ground the negative lead. With the engine running, the voltage should fluctuate between 0.1V and 0.9V. A steady reading indicates a faulty sensor.

Testing the Coolant Temperature Sensor

Set the multimeter to resistance (ohms). Disconnect the sensor and measure resistance across its terminals. Compare the reading to the specs in your manual—resistance should decrease as the engine warms up.

Testing the Throttle Position Sensor

Set the multimeter to DC voltage. With the ignition on, probe the signal wire. As you slowly open the throttle, the voltage should rise smoothly from around 0.5V to 4.5V. A jumpy or dead reading suggests a bad TPS.

Common Mistakes to Avoid

Even experienced DIYers can make errors when diagnosing the 1992 300ZX. Here are some pitfalls to watch out for:

- Misreading flash patterns: Count carefully—long and short flashes can be easy to mix up in low light.

- Grounding the wrong terminal: Double-check the TEN and GND pins before connecting the wire.

- Starting the engine with the wire connected: This can damage the ECU or cause inaccurate readings.

- Replacing parts without testing: Always verify a sensor is faulty before buying a replacement.

- Ignoring vacuum leaks: A cracked hose can mimic sensor problems—inspect all vacuum lines.

Maintaining Your 1992 Nissan 300ZX in 2026

As a classic car, your 300ZX requires extra care to stay reliable. Here are some maintenance tips:

- Replace aging sensors: O2 sensors, knock sensors, and TPS units degrade over time—consider replacing them preventively.

- Inspect wiring harnesses: Look for cracked insulation, rodent damage, or corrosion—especially near the engine and firewall.

- Use high-quality fuel and oil: Modern ethanol-blended fuels can harm older fuel systems. Use fuel stabilizer if the car sits for long periods.

- Check the timing belt: If not replaced in the last 60,000 miles, do it soon—failure can destroy the engine.

- Join a community: Online forums and local car clubs are great resources for parts, advice, and troubleshooting.

When to See a Mechanic

While many issues can be resolved at home, some problems require professional help. Seek a mechanic if:

- The check engine light flashes continuously (indicating a severe misfire)

- You suspect ECU or wiring harness damage

- Multiple codes appear and you can’t isolate the cause

- The car runs poorly even after repairs

Look for a shop experienced with early 90s Japanese performance cars—they’ll have the right tools and knowledge.

Conclusion

Checking the engine light on a 1992 Nissan 300ZX doesn’t require a scanner or a trip to the dealership. With a simple wire, a flashlight, and this guide, you can read diagnostic trouble codes, identify common problems, and take action to keep your classic Z running smoothly.

Remember: the key is patience and attention to detail. Count the flashes carefully, test components before replacing them, and always reset the ECU after repairs. By understanding your car’s OBD1 system, you’re not just fixing a light—you’re preserving a piece of automotive history.

Whether you’re tuning your 300ZX for weekend drives or preparing it for a car show in 2026, this skill will save you time, money, and frustration. So the next time that check engine light comes on, you’ll know exactly what to do.