Code P0131 indicates a low voltage issue with your upstream oxygen (O2) sensor on Bank 1. This guide walks you through diagnosing and fixing the problem, from inspecting wiring to replacing the sensor—saving you time and money.

Key Takeaways

- Understand what P0131 means: It signals a low voltage condition in the upstream O2 sensor (Bank 1, Sensor 1), often caused by a lean fuel mixture or faulty sensor.

- Check for related symptoms: Poor fuel economy, rough idling, or hesitation during acceleration can accompany this code.

- Inspect wiring and connections first: Damaged, corroded, or loose wires are common culprits and cheaper to fix than replacing the sensor.

- Test the O2 sensor with a multimeter: Verify if the sensor is truly faulty before buying a replacement.

- Use OEM or high-quality aftermarket parts: Cheap sensors may fail prematurely and trigger the code again.

- Clear the code after repairs: Use an OBD2 scanner to reset the check engine light and confirm the fix worked.

- Prevent future issues: Keep your fuel system clean and address engine performance problems promptly.

How to Fix Check Engine Light Code P0131

Seeing the check engine light pop up on your dashboard can be stressful—especially when you don’t know what’s causing it. If your OBD2 scanner shows code P0131, you’re dealing with a low voltage issue in your upstream oxygen (O2) sensor on Bank 1. Don’t panic. This is a common problem, and in many cases, it’s fixable at home with basic tools and a little patience.

In this comprehensive guide, you’ll learn exactly what P0131 means, why it happens, and how to diagnose and fix it step by step. Whether you’re a DIY enthusiast or just trying to save on repair costs, this guide will walk you through everything from inspecting wiring to replacing the sensor. By the end, you’ll not only clear that pesky check engine light but also understand how your car’s emissions system works—and how to keep it running smoothly.

What Is Code P0131?

Code P0131 is a diagnostic trouble code (DTC) that stands for “O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1).” Let’s break that down:

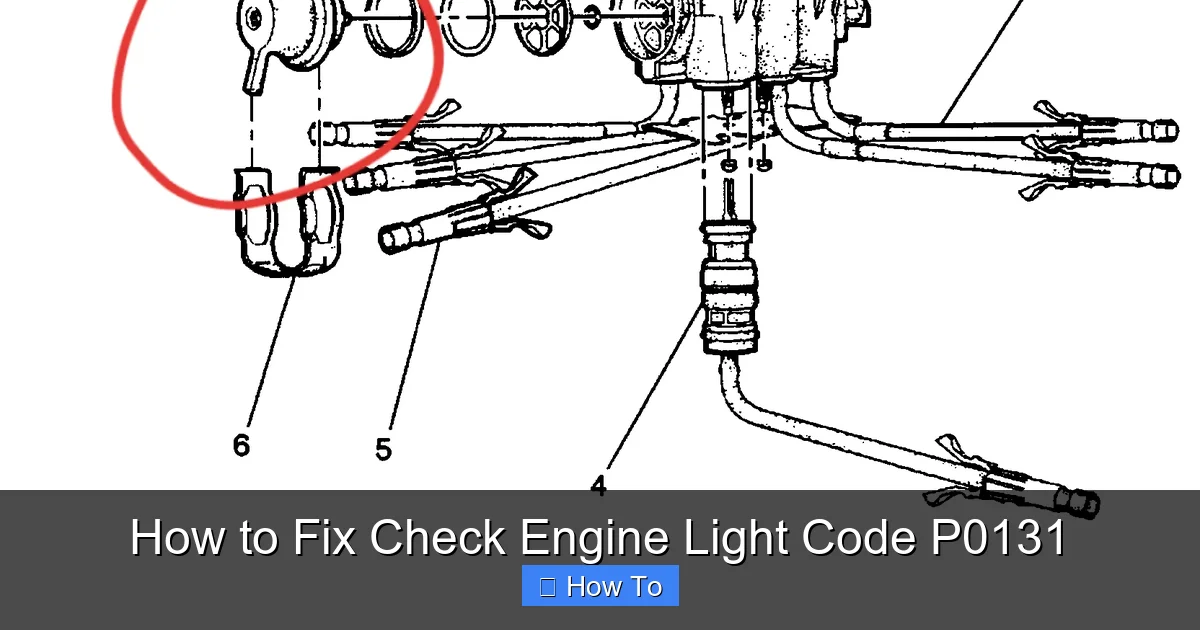

Visual guide about How to Fix Check Engine Light Code P0131

Image source: dodgecheckenginelight.com

- O2 Sensor: This is the oxygen sensor, which monitors the amount of oxygen in your exhaust gases. It helps your engine control module (ECM) adjust the air-fuel mixture for optimal performance and emissions.

- Bank 1: This refers to the side of the engine that contains cylinder #1. In most inline engines, there’s only one bank. In V6 or V8 engines, Bank 1 is usually the side where cylinder #1 is located (check your owner’s manual if unsure).

- Sensor 1: This is the upstream sensor, located before the catalytic converter. It’s the primary sensor used to adjust fuel trim.

- Low Voltage: The sensor is reporting a voltage that’s consistently below the expected range, typically below 0.1 volts. This suggests a lean condition—too much oxygen and not enough fuel in the exhaust.

When the ECM detects this low voltage signal over a period of time, it triggers the P0131 code and turns on the check engine light. The engine may still run, but fuel efficiency and emissions can suffer.

Common Causes of P0131

Before jumping into repairs, it’s important to understand what might be causing the low voltage reading. Here are the most common culprits:

1. Faulty Oxygen Sensor

The O2 sensor itself may be worn out or damaged. Over time, sensors can become contaminated by oil, coolant, or fuel additives, leading to inaccurate readings. A failing sensor often reads low voltage because it can’t generate a proper signal.

2. Vacuum Leaks

A vacuum leak allows unmetered air into the intake manifold, creating a lean condition. This extra oxygen fools the O2 sensor into thinking the fuel mixture is too lean, causing it to output a low voltage signal. Common leak spots include cracked hoses, intake gaskets, or the PCV valve.

3. Exhaust Leaks

Leaks in the exhaust system before the O2 sensor (like a cracked manifold or loose flange) can let outside air enter the exhaust stream. This dilutes the exhaust gases with oxygen, again causing a false lean reading.

4. Wiring or Connector Issues

Damaged, corroded, or loose wiring to the O2 sensor can disrupt the signal. The sensor relies on a clean electrical connection to send accurate data to the ECM. Even a small break or corrosion can cause low voltage readings.

5. Fuel Delivery Problems

A weak fuel pump, clogged fuel filter, or failing fuel injectors can reduce fuel delivery, leading to a lean mixture. This causes the O2 sensor to detect excess oxygen and report low voltage.

6. Engine Misfires

Misfires can send unburned oxygen into the exhaust, triggering a lean signal. While this usually triggers other codes (like P0300), it can contribute to P0131 if the misfire is intermittent.

Tools and Supplies You’ll Need

Before starting, gather these tools and parts. Most are available at auto parts stores or online:

- OBD2 scanner (to read and clear codes)

- Digital multimeter (for testing voltage and resistance)

- O2 sensor socket or wrench (typically 22mm)

- Penetrating oil (like WD-40 or PB Blaster)

- Wire brush or sandpaper

- Electrical contact cleaner

- Replacement O2 sensor (if needed)

- Safety gloves and eye protection

- Jack and jack stands (if the sensor is underneath the vehicle)

Tip: If you’re unsure about the sensor location, consult your vehicle’s service manual or look up a diagram online. Most upstream sensors are mounted on the exhaust manifold or downpipe.

Step-by-Step Guide to Fixing P0131

Step 1: Confirm the Code and Check for Other Issues

Start by using your OBD2 scanner to confirm that P0131 is the active code. Also, check for any pending or stored codes. If you see codes like P0171 (system too lean) or P0300 (random misfire), those could be related and should be addressed together.

Next, take note of any symptoms:

- Rough idle

- Poor fuel economy

- Hissing sound (possible vacuum leak)

- Reduced power or hesitation

These clues can help pinpoint the root cause.

Step 2: Perform a Visual Inspection

With the engine off and cool, inspect the O2 sensor and its wiring:

- Look for frayed, melted, or damaged wires near the sensor.

- Check the connector for corrosion, dirt, or loose pins.

- Inspect the exhaust manifold and downpipe for cracks or leaks.

- Listen for hissing sounds around the intake manifold (sign of vacuum leak).

If you find obvious damage—like a cracked wire or loose connector—repair or clean it before proceeding. Sometimes, simply reseating the connector fixes the issue.

Step 3: Test the O2 Sensor Voltage

To determine if the sensor is truly faulty, test its output voltage using a multimeter.

How to Test:

- Start the engine and let it idle until it reaches operating temperature (coolant temp around 190°F).

- Locate the O2 sensor connector and disconnect it.

- Identify the signal wire (usually black or white—check your vehicle’s wiring diagram).

- Set your multimeter to DC voltage (2V range).

- Connect the red probe to the signal wire and the black probe to ground (engine block or battery negative).

- Observe the voltage reading.

A healthy O2 sensor should fluctuate between 0.1V and 0.9V as the engine runs. If it stays below 0.1V most of the time, that confirms the low voltage condition.

Tip: Rev the engine slightly. The voltage should rise briefly. If it doesn’t respond, the sensor may be dead.

Step 4: Check for Vacuum and Exhaust Leaks

Since leaks can mimic a faulty sensor, inspect the intake and exhaust systems.

For Vacuum Leaks:

- Spray carburetor cleaner or propane around hoses, gaskets, and the intake manifold while the engine is running.

- If the engine RPM increases, you’ve found a leak.

- Replace cracked hoses or reseal gaskets as needed.

For Exhaust Leaks:

- Listen for hissing near the manifold and downpipe.

- Use a piece of cardboard to block the tailpipe briefly (only for a few seconds) to build backpressure—this can make leaks more audible.

- Repair or replace damaged components.

Step 5: Test Fuel Pressure (Optional but Recommended)

If no leaks are found, check fuel pressure to rule out delivery issues.

- Use a fuel pressure gauge attached to the fuel rail.

- Compare readings to your vehicle’s specifications (usually 35–45 psi for port injection).

- Low pressure may indicate a weak pump, clogged filter, or bad regulator.

If fuel pressure is low, address the fuel system issue before replacing the O2 sensor.

Step 6: Replace the O2 Sensor (If Necessary)

If all other checks pass and the sensor still reads low voltage, it’s time to replace it.

How to Replace:

- Allow the engine to cool completely.

- Raise the vehicle safely using a jack and secure it with jack stands.

- Spray the sensor threads with penetrating oil and let it soak for 10–15 minutes.

- Use an O2 sensor socket or wrench to loosen and remove the old sensor.

- Apply anti-seize compound to the threads of the new sensor (unless it’s pre-coated).

- Install the new sensor and tighten to the manufacturer’s torque specification (usually 30–50 ft-lbs).

- Reconnect the electrical connector.

- Lower the vehicle.

Important: Use a high-quality sensor. OEM (original equipment manufacturer) or reputable brands like Bosch, Denso, or NTK are recommended. Cheap sensors often fail quickly and may not resolve the code.

Step 7: Clear the Code and Test Drive

After repairs, clear the P0131 code using your OBD2 scanner. Then, take the car for a test drive.

- Drive normally for at least 10–15 minutes, including highway speeds.

- Monitor the check engine light—if it stays off, the fix worked.

- Use the scanner to check for pending codes after the drive.

If the light returns, recheck your work or consider professional diagnosis.

Troubleshooting Tips

Even after following these steps, P0131 can sometimes persist. Here’s what to do:

The Code Keeps Coming Back

- Double-check all connections and wiring.

- Ensure the new sensor is compatible with your vehicle.

- Verify there are no hidden vacuum or exhaust leaks.

- Check for software updates for your ECM (some vehicles have TSBs for O2 sensor issues).

The Sensor Reads Low Voltage But Everything Else Is Fine

In rare cases, the ECM itself may be faulty or misinterpreting the signal. This is uncommon but possible. A professional scan tool with live data monitoring can help determine if the ECM is at fault.

You Don’t Have a Multimeter

If you can’t test the sensor yourself, many auto parts stores offer free code reading and basic diagnostics. They may even test the sensor for you.

Preventing Future P0131 Codes

Once you’ve fixed the issue, take steps to avoid it happening again:

- Use high-quality fuel and avoid contaminated gas.

- Replace spark plugs and ignition coils on schedule to prevent misfires.

- Inspect vacuum hoses annually and replace brittle ones.

- Keep the exhaust system in good condition—repair rust or damage promptly.

- Use fuel system cleaners periodically to prevent carbon buildup.

Regular maintenance goes a long way in preventing sensor and emissions issues.

Conclusion

Fixing check engine light code P0131 doesn’t have to be intimidating. By understanding what the code means and following a systematic approach—starting with inspection, testing, and only replacing parts when necessary—you can resolve the issue efficiently and affordably.

Remember, the O2 sensor plays a vital role in your engine’s performance and emissions. A faulty sensor not only triggers the check engine light but can also reduce fuel economy and increase pollution. Taking the time to diagnose and fix P0131 properly ensures your vehicle runs cleaner, smoother, and more efficiently.

Whether you tackled a simple wiring fix or replaced the sensor entirely, you’ve taken control of your car’s health. And with the tools and knowledge from this guide, you’re ready to handle future repairs with confidence.