Discover how to diagnose and respond to the check engine light in your 2007 Ford F-250. This guide walks you through reading error codes, using OBD2 scanners, and understanding common causes—so you can fix issues fast and avoid costly repairs.

Key Takeaways

- Locate the OBD2 port under the dashboard near the driver’s side. It’s typically found below the steering column and is essential for connecting diagnostic tools.

- Use an OBD2 scanner to read trouble codes. Even basic scanners can retrieve codes like P0300 (random misfire) or P0420 (catalyst efficiency), helping pinpoint problems.

- Don’t ignore the check engine light—even if the truck runs fine. Some issues, like a failing oxygen sensor, may not show immediate symptoms but can hurt fuel economy and emissions.

- Clear codes only after repairs are made. Simply clearing codes without fixing the root cause will cause the light to return.

- Common 2007 F-250 issues include EGR valve faults, gas cap leaks, and MAF sensor problems. These are often easy and inexpensive to fix.

- Keep a repair log and save scanner readings. This helps track recurring issues and improves communication with mechanics.

- Consider upgrading to a Bluetooth OBD2 scanner in 2026. Many new apps offer real-time data, code definitions, and repair suggestions right on your smartphone.

How to Check Check Engine Light in 07 Ford F-250

If you own a 2007 Ford F-250, you know it’s a rugged, reliable workhorse built to handle heavy loads and tough conditions. But like any vehicle, it’s not immune to mechanical hiccups—and one of the first signs something might be off is the dreaded check engine light. Whether it’s flashing steadily or blinking intermittently, that little orange icon on your dashboard is your truck’s way of saying, “Hey, I need attention.”

In this comprehensive guide, we’ll walk you through exactly how to check the check engine light in your 2007 Ford F-250. You’ll learn how to read diagnostic trouble codes (DTCs), use an OBD2 scanner, interpret common codes, and decide whether to fix the issue yourself or visit a mechanic. We’ll also cover troubleshooting tips, maintenance advice, and how modern tools in 2026 make diagnosing your truck easier than ever.

By the end of this guide, you’ll feel confident handling the check engine light—no mechanic required. Let’s get started.

Why the Check Engine Light Comes On

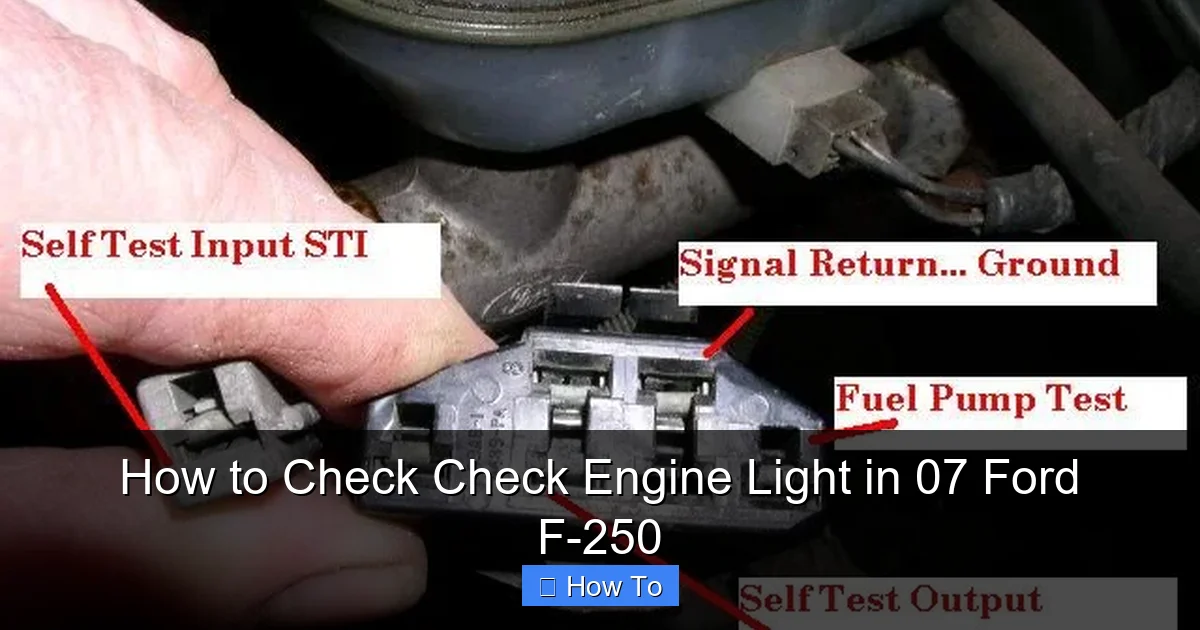

Visual guide about How to Check Check Engine Light in 07 Ford F-250

Image source: i.pinimg.com

Before diving into the steps, it’s important to understand why the check engine light might illuminate in your 2007 F-250. This light is part of your truck’s onboard diagnostics system (OBD2), which monitors engine performance, emissions, and various sensors. When the system detects a problem that could affect emissions or engine function, it triggers the light and stores a trouble code.

Common reasons include:

- A loose or faulty gas cap (one of the most frequent causes)

- Misfiring engine (often due to bad spark plugs or coils)

- Faulty oxygen (O2) sensor

- Mass airflow (MAF) sensor issues

- Exhaust gas recirculation (EGR) valve problems

- Catalytic converter inefficiency

- Evaporative emissions system leaks

In 2026, with advancements in vehicle diagnostics, many of these issues can be caught early—before they lead to serious damage. The key is acting quickly and correctly.

Tools You’ll Need

You don’t need to be a mechanic to check your check engine light. With just a few tools, you can diagnose the issue yourself:

- OBD2 Scanner: This is the most important tool. Basic models start around $20 and plug directly into your truck’s diagnostic port. For 2026, consider a Bluetooth-enabled scanner that pairs with your smartphone for real-time data and code explanations.

- Smartphone or Tablet (optional): If using a Bluetooth scanner, you’ll need a device to run the companion app (like Torque Pro, OBD Fusion, or Ford’s own diagnostic tools).

- Flashlight: Helps you locate the OBD2 port, especially if it’s tucked away.

- Notepad or Digital Notes App: To record trouble codes and observations.

- Gloves (optional): Keeps your hands clean when working under the dashboard.

Most OBD2 scanners come with simple instructions, and many apps offer step-by-step guidance. You don’t need advanced technical skills—just patience and attention to detail.

Step 1: Locate the OBD2 Port

The first step in checking your check engine light is finding the OBD2 (On-Board Diagnostics) port. This is where you’ll plug in your scanner to communicate with your truck’s computer.

In the 2007 Ford F-250, the OBD2 port is typically located:

- Under the dashboard on the driver’s side

- Just below the steering column

- Within arm’s reach when seated in the driver’s seat

It’s a 16-pin connector, usually black or gray, and shaped like a trapezoid. It may be covered by a small plastic flap or tucked behind a panel. Use your flashlight if needed to spot it.

Pro Tip: If you can’t find it, check behind the fuse panel cover or near the parking brake. Some F-250 models have it slightly recessed, so don’t force anything—gently feel around with your hand.

Once located, make sure the port is clean and free of debris. Dust or corrosion can interfere with the connection.

Step 2: Turn the Ignition to the “On” Position

Before plugging in your scanner, you need to power up the truck’s electrical system—but you don’t need to start the engine.

Here’s how:

- Insert your key into the ignition.

- Turn it to the “ON” position (also called “Run” or “Ignition On”). This powers the dashboard and computer systems.

- Do not start the engine unless instructed by your scanner’s manual.

You’ll see all the dashboard lights illuminate, including the check engine light. This confirms the system is active and ready for diagnostics.

Note: Some scanners require the engine to be running, but most only need the ignition on. Always check your scanner’s instructions.

Step 3: Connect the OBD2 Scanner

Now it’s time to plug in your scanner:

- Take your OBD2 scanner and align the connector with the port.

- Gently push it in until it clicks or feels secure. Don’t force it—OBD2 ports are designed to fit one way.

- If using a Bluetooth scanner, ensure it’s charged and paired with your phone or tablet.

Once connected, the scanner should power on automatically. You’ll usually see a welcome screen or a prompt to begin diagnostics.

Troubleshooting Tip: If the scanner doesn’t turn on, double-check the ignition is on, the port is clean, and the scanner is fully inserted. Try unplugging and reconnecting.

Step 4: Read the Trouble Codes

This is the core of the process. Your scanner will communicate with the truck’s computer and retrieve any stored trouble codes.

Follow these steps:

- On the scanner, select “Read Codes” or “Scan” from the menu.

- Wait a few seconds as the device communicates with the engine control module (ECM).

- The scanner will display one or more trouble codes, usually in the format “P0XXX” (e.g., P0301, P0420).

Each code corresponds to a specific issue. For example:

- P0300: Random/Multiple Cylinder Misfire Detected

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

- P0171: System Too Lean (Bank 1)

- P0455: Evaporative Emission Control System Leak Detected (large leak)

Write down all codes—even if there are multiple. They help prioritize repairs.

Pro Tip: Use your smartphone to take a photo of the codes or save them in a notes app. This makes it easier to research or share with a mechanic later.

Step 5: Interpret the Codes

Now that you have the codes, it’s time to understand what they mean.

Most OBD2 scanners come with a built-in code library, or you can use free online resources like:

- OBD-Codes.com

- Ford-specific forums (e.g., Ford Truck Enthusiasts)

- YouTube tutorials for 2007 F-250 common issues

Here’s a quick breakdown of common 2007 F-250 codes:

P0300 – Random Misfire

This means one or more cylinders aren’t firing properly. Causes include:

- Worn spark plugs

- Faulty ignition coils

- Fuel delivery issues

- Low compression

Action: Check spark plugs and coils first—they’re inexpensive and easy to replace.

P0420 – Catalyst Efficiency

Your catalytic converter isn’t cleaning exhaust gases effectively. Possible causes:

- Failing catalytic converter

- Faulty O2 sensor

- Engine running rich (too much fuel)

Action: Don’t ignore this—driving with a bad catalytic converter can damage other components. Have it inspected.

P0455 – Large EVAP Leak

This often points to a loose or cracked gas cap.

Action: Tighten the gas cap and clear the code. If the light returns, inspect the cap and EVAP system hoses.

P0171 – System Too Lean

The engine is getting too much air or not enough fuel. Common causes:

- Vacuum leaks

- Dirty MAF sensor

- Weak fuel pump

Action: Clean the MAF sensor with MAF cleaner spray. Check for cracked hoses.

Step 6: Clear the Codes (After Repair)

Once you’ve identified and fixed the issue, you can clear the trouble codes.

- On your scanner, select “Clear Codes” or “Erase DTCs.”

- Confirm the action when prompted.

- The check engine light should turn off.

Important: Only clear codes after making repairs. Clearing them without fixing the problem will cause the light to return—and you’ll lose valuable diagnostic information.

If the light comes back on within a few days, the issue wasn’t fully resolved. Re-scan and investigate further.

Step 7: Monitor and Maintain

Checking the check engine light isn’t a one-time task. To keep your 2007 F-250 running smoothly in 2026 and beyond, follow these maintenance tips:

- Check the gas cap regularly. A loose cap is the #1 cause of EVAP codes. Make sure it clicks when tightened.

- Replace spark plugs every 30,000–50,000 miles. The 2007 F-250 uses 8 plugs—consider upgrading to iridium for longer life.

- Clean the MAF sensor every 15,000 miles. Use a dedicated MAF cleaner—never touch the sensor wires.

- Inspect vacuum hoses for cracks or leaks. Brittle hoses are common in older trucks.

- Use high-quality fuel and additives. Fuel system cleaners can help prevent injector clogs.

Troubleshooting Common Issues

Even with the right tools, you might run into problems. Here’s how to handle them:

Scanner Won’t Connect

- Ensure the ignition is on.

- Check for a blown fuse (usually in the passenger compartment fuse box).

- Try a different scanner or port.

Codes Keep Returning

This means the underlying issue isn’t fixed. For example, a P0420 code may return if the O2 sensor is bad, not just the catalytic converter. Re-inspect and test components.

Check Engine Light Flashes While Driving

A flashing light indicates a severe misfire that can damage the catalytic converter. Pull over safely and turn off the engine. Have the truck towed to a repair shop.

No Codes Found

Sometimes the light comes on due to intermittent issues or sensor glitches. Drive the truck for a few days and re-scan. If the light stays off, it may have been a temporary fault.

When to See a Mechanic

While many check engine light issues can be DIY-fixed, some require professional help:

- Internal engine problems (e.g., low compression, timing issues)

- Transmission faults

- Complex electrical issues

- When you’re unsure of the diagnosis

If you’ve tried basic fixes and the light persists, it’s time to visit a trusted mechanic—especially one familiar with Ford trucks.

Conclusion

Checking the check engine light in your 2007 Ford F-250 doesn’t have to be intimidating. With an OBD2 scanner and this guide, you can diagnose issues quickly, save money on diagnostics, and keep your truck running strong.

Remember:

- Locate the OBD2 port under the dashboard.

- Use a scanner to read and interpret trouble codes.

- Address the root cause before clearing codes.

- Maintain your truck regularly to prevent future issues.

In 2026, with smarter tools and better resources, taking control of your vehicle’s health is easier than ever. Don’t let that check engine light scare you—use it as a helpful warning system. Your F-250 has served you well; now it’s time to return the favor.