Discover how to read check engine light codes on your 1992 Ford F150 without expensive tools. This guide walks you through the built-in OBD-I self-diagnostic system using a paperclip or jumper wire to retrieve trouble codes directly from the truck’s computer.

Key Takeaways

- No scanner required: The 1992 F150 uses OBD-I, allowing you to read codes manually using a simple jumper wire or paperclip.

- Locate the DLC under the hood: The Data Link Connector is typically found near the driver’s side fender, under the hood—not under the dash like newer models.

- Use key-on-engine-off (KOEO) mode: Turn the ignition to “ON” without starting the engine to trigger the diagnostic flash sequence.

- Interpret flashes as digits: Long and short flashes correspond to numbers—e.g., two long flashes + three short = code 23.

- Clear codes manually: Disconnect the battery or use the diagnostic mode to reset the check engine light after repairs.

- Common 1992 F150 codes include: EGR flow issues (code 32), oxygen sensor faults (code 13), and MAP sensor problems (code 14).

- Document everything: Write down codes and symptoms before clearing them to track recurring issues over time.

How to Check Engine Light Code on 92 F150: A Complete 2026 Guide

If you’re driving a classic 1992 Ford F150 and the dreaded check engine light pops on, don’t panic—especially if you’re in 2026 and modern OBD-II scanners feel like overkill for this old-school workhorse. The good news? Your truck has a built-in diagnostic system that lets you read trouble codes without any fancy equipment. No need for Bluetooth adapters, smartphone apps, or expensive code readers. All you need is a paperclip, a few minutes, and this step-by-step guide.

In this comprehensive how-to, you’ll learn exactly how to check engine light code on a 92 F150 using the truck’s original OBD-I (On-Board Diagnostics, Version 1) system. We’ll walk you through locating the diagnostic port, retrieving codes manually, interpreting the flash patterns, and even clearing the light once the issue is fixed. Whether you’re a weekend mechanic, a classic truck enthusiast, or just trying to save a few bucks on diagnostics, this guide has you covered.

By the end, you’ll be able to confidently diagnose common engine problems, understand what those blinking lights really mean, and keep your F150 running strong—even decades after it rolled off the assembly line.

Why the 1992 F150 Uses OBD-I (And Why It Matters)

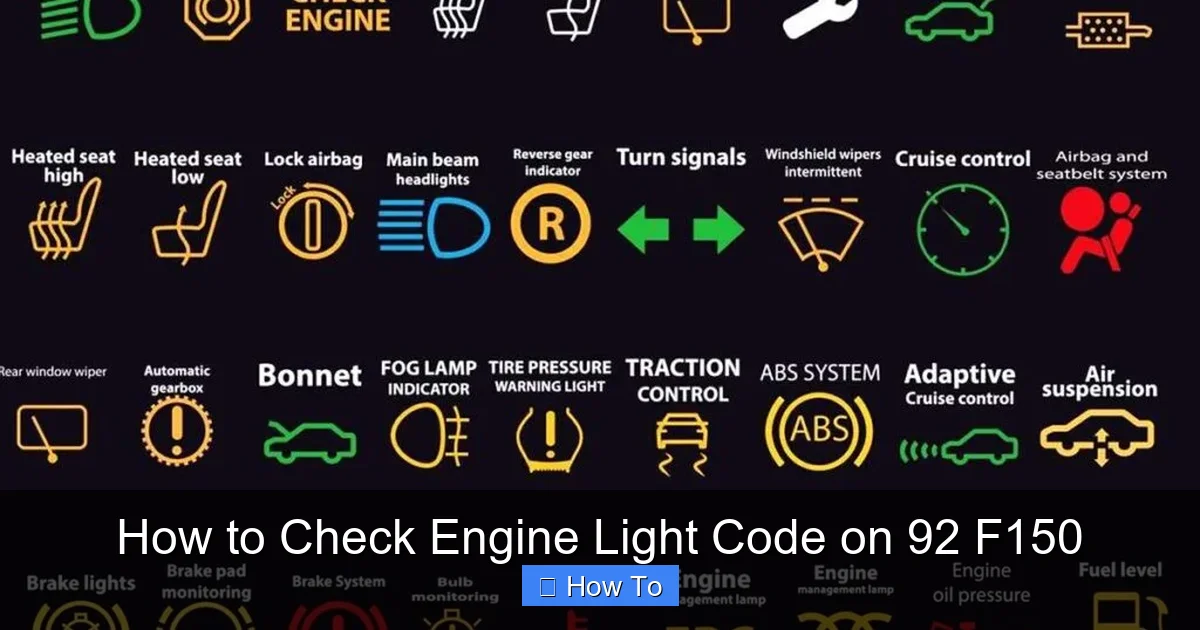

Visual guide about How to Check Engine Light Code on 92 F150

Image source: guidemechanic.com

Before we dive into the steps, it’s important to understand why your 1992 Ford F150 doesn’t use the same diagnostic system as modern vehicles. In 1996, the U.S. government mandated that all vehicles use OBD-II, a standardized system that allows universal scanners to read codes across all makes and models. But the 1992 F150 predates that rule—it uses OBD-I, a manufacturer-specific system that Ford designed for its vehicles of that era.

OBD-I isn’t as advanced as OBD-II, but it’s still incredibly useful. It monitors key engine functions like ignition timing, fuel delivery, emissions systems, and sensor inputs. When something goes wrong, the truck’s onboard computer—called the EEC-IV (Electronic Engine Control, Version 4)—stores a trouble code and triggers the check engine light.

The big advantage of OBD-I on the 92 F150? You can read codes manually. No scanner needed. That means even if you’re out in the middle of nowhere with no cell service or power, you can still figure out what’s going on under the hood.

Tools and Supplies You’ll Need

The beauty of diagnosing your 1992 F150 is how little you need to get started. Here’s a quick checklist:

- A paperclip or jumper wire: This is used to bridge two terminals in the diagnostic port. A standard paperclip works fine—just straighten it out.

- A pen and notepad: You’ll want to write down the codes as they flash.

- Flashlight (optional): The diagnostic port is under the hood and can be hard to see in low light.

- Basic understanding of your truck: Know where the battery, fuse box, and engine components are located.

That’s it. No multimeter, no laptop, no subscription-based diagnostic software. Just simple, reliable, old-school troubleshooting.

Step 1: Locate the Data Link Connector (DLC)

The first step in checking your engine light code is finding the Data Link Connector—the port where you’ll plug in your paperclip or jumper wire. On the 1992 F150, this port is not under the dashboard like in newer trucks. Instead, it’s located under the hood, on the driver’s side.

Where to Look

Open the hood and look along the driver’s side fender wall, near the firewall. You’re looking for a small, rectangular plastic connector with 6 to 8 pins inside. It’s usually mounted on a bracket or clipped to a wiring harness. It may be labeled “DLC” or “Self-Test Connector,” but even if it’s not, you’ll recognize it by its shape and location.

If you’re having trouble finding it, here’s a helpful tip: trace the wiring from the engine control module (ECM), which is usually mounted on the driver’s side firewall. The DLC is often connected to the same harness.

What It Looks Like

The DLC on a 1992 F150 typically has 6 pins arranged in two rows of three. The exact pinout can vary slightly depending on the engine (4.9L inline-6, 5.0L V8, or 5.8L V8), but the most important pins for reading codes are usually:

- Pin A: Signal Ground (usually black wire)

- Pin B: Self-Test Input (usually yellow or orange wire)

You’ll be bridging these two pins with your paperclip or jumper wire to trigger the diagnostic mode.

Step 2: Prepare the Truck for Diagnostics

Before you start reading codes, make sure your truck is in the right condition. This ensures accurate results and prevents false readings.

Turn Off the Engine and Accessories

Make sure the engine is completely off. Turn the key to the “OFF” position and remove it from the ignition. Also, turn off all electrical accessories—radio, lights, AC, etc. This reduces electrical noise and ensures the computer isn’t distracted by other systems.

Ensure the Battery Is Connected

The EEC-IV system needs power to run diagnostics. Make sure the battery is connected and has a good charge. If the battery is weak or disconnected, the computer may not store or display codes correctly.

Check the Check Engine Light

Look at the dashboard. Is the check engine light on? If it’s not, the computer may not have stored any active codes. However, it’s still possible to retrieve “hard” codes (current issues) or “intermittent” codes (past issues that triggered the light before). We’ll cover both in a moment.

Step 3: Bridge the DLC Pins

Now it’s time to activate the self-test mode. This is where the paperclip or jumper wire comes in.

Straighten the Paperclip

Take a standard paperclip and straighten it out so you have a long, straight piece of metal. You only need about 2–3 inches to make the connection.

Insert the Paperclip into the DLC

Carefully insert one end of the paperclip into Pin A (Signal Ground) and the other end into Pin B (Self-Test Input). You don’t need to force it—just gently push it into the slots until it makes contact. The pins are small, so take your time.

Pro Tip: If you’re unsure which pins are A and B, look for a diagram on the DLC cover or in your owner’s manual. If there’s no label, Pin A is usually the top-left pin, and Pin B is the top-right pin when facing the connector.

Double-Check the Connection

Make sure the paperclip is securely in both pins and not touching any other metal parts. A loose connection can cause erratic flashing or no response at all.

Step 4: Turn the Key to “ON” (Engine Off)

With the paperclip in place, it’s time to power up the diagnostic system.

Turn the Ignition to “ON”

Insert the key and turn it to the “ON” position—but do not start the engine. You should see the dashboard lights come on, including the check engine light. This is called Key-On, Engine-Off (KOEO) mode, and it’s the standard way to access stored trouble codes.

Watch for the Flash Sequence

Within a few seconds, the check engine light should start flashing. These flashes represent the trouble codes stored in the computer. The pattern is simple: long flashes are tens digits, short flashes are ones digits.

For example:

- One long flash + four short flashes = Code 14

- Two long flashes + three short flashes = Code 23

- Three long flashes + two short flashes = Code 32

The light will pause between codes, then repeat the sequence. It may show multiple codes if there are several issues.

Write Down the Codes

As the light flashes, write down each code in order. Don’t worry if it repeats—the system will cycle through all stored codes at least once. If you miss a code, wait for the sequence to repeat.

Example: If the light flashes: long-long-short-short-short, that’s 2 long (20) + 3 short (3) = Code 23.

Step 5: Interpret the Trouble Codes

Once you’ve recorded the codes, it’s time to figure out what they mean. The 1992 F150 uses a standardized set of OBD-I codes, but they’re specific to Ford’s EEC-IV system.

Common 1992 F150 Trouble Codes

Here are some of the most frequent codes you might encounter:

- Code 13: Oxygen sensor circuit malfunction (front O2 sensor)

- Code 14: Cylinder head temperature sensor out of range

- Code 15: Throttle position sensor (TPS) voltage high

- Code 17: Engine coolant temperature (ECT) sensor out of range

- Code 21: Mass Air Flow (MAF) sensor low input

- Code 23: Throttle position sensor (TPS) voltage low

- Code 32: Exhaust Gas Recirculation (EGR) flow insufficient

- Code 41: Oxygen sensor indicates lean condition (front)

- Code 51: System passes self-test (no fault detected)

- Code 54: Air Charge Temperature (ACT) sensor out of range

Note: Code 51 is actually a good sign—it means the system didn’t find any active faults during the self-test.

Hard Codes vs. Intermittent Codes

The EEC-IV system stores two types of codes:

- Hard Codes: Current, active problems that are happening right now. These will trigger the check engine light and appear during KOEO mode.

- Intermittent Codes: Past issues that triggered the light but may not be present now. These are stored in memory and can be retrieved using a different method (more on that below).

If you only get Code 51, it could mean there’s no current issue—or the problem is intermittent and not active at the moment.

Step 6: Retrieve Intermittent Codes (Optional)

If you suspect a past issue or want a complete diagnostic picture, you can retrieve intermittent codes using the same DLC.

Perform a Key-On, Engine-Running (KOER) Test

With the paperclip still in place, start the engine and let it idle. The computer will now run a more advanced self-test, checking sensors under real operating conditions.

Watch for Additional Flashes

The check engine light may flash new codes that didn’t appear in KOEO mode. These are often related to dynamic systems like the EGR valve, MAF sensor, or ignition timing.

Caution: Only perform KOER if you’re in a safe, well-ventilated area. Never rev the engine excessively during this test.

Compare with KOEO Results

Compare the codes from KOEO and KOER. If new codes appear during KOER, they’re likely related to systems that only activate when the engine is running.

Step 7: Clear the Check Engine Light

Once you’ve diagnosed the problem and made repairs, you’ll want to clear the codes and turn off the check engine light.

Method 1: Disconnect the Battery

The simplest way to clear codes is to disconnect the negative terminal of the battery for at least 10–15 minutes. This resets the EEC-IV computer and erases all stored trouble codes.

Steps:

- Turn off the engine and remove the key.

- Use a wrench to loosen the negative battery cable.

- Disconnect the cable and wait 15 minutes.

- Reconnect the cable and tighten it securely.

Note: This method also resets radio presets, clock, and other memory settings.

Method 2: Use the Diagnostic Mode

You can also clear codes without disconnecting the battery by using the DLC.

Steps:

- With the paperclip still in the DLC, turn the key to “ON” (engine off).

- Wait for the codes to flash.

- Turn the key to “OFF” and remove the paperclip.

- Turn the key back to “ON” and watch the check engine light.

If the light stays off, the codes have been cleared. If it comes back on, the problem may still exist.

Troubleshooting Common Issues

Even with this guide, you might run into a few hiccups. Here’s how to handle the most common problems.

No Flashes at All

If the check engine light doesn’t flash when you turn the key to “ON” with the paperclip in place, check the following:

- Battery voltage: Use a multimeter to ensure the battery has at least 12 volts.

- Paperclip connection: Make sure it’s firmly in both Pin A and Pin B.

- Blown fuse: Check the EEC power fuse in the fuse box (usually 10A or 15A).

- Faulty DLC: The connector may be corroded or damaged. Clean it with electrical contact cleaner.

Erratic or Inconsistent Flashing

If the light flashes randomly or skips codes, it could indicate:

- Loose paperclip: Reinsert it firmly.

- Weak battery: Charge or replace the battery.

- Faulty EEC-IV module: In rare cases, the computer itself may be failing.

Check Engine Light Comes Back On

If the light returns after clearing codes, the underlying problem hasn’t been fixed. Revisit your diagnosis and double-check the repair. Some issues, like a bad oxygen sensor or EGR valve, may require replacement—not just cleaning.

Final Tips for 2026 and Beyond

Even in 2026, the 1992 F150 remains a reliable and beloved truck. Here are a few modern tips to keep your diagnostics accurate:

- Use a digital camera: Record the flash sequence on your phone to review it later.

- Keep a code log: Track codes over time to spot patterns.

- Upgrade sensors if needed: Modern aftermarket sensors can improve performance and diagnostics.

- Join online forums: Communities like Ford Truck Enthusiasts or Reddit’s r/FordTrucks can offer real-time help.

Conclusion

Checking the engine light code on a 1992 Ford F150 doesn’t require a trip to the mechanic or a $200 scanner. With just a paperclip and a few minutes, you can access the truck’s built-in diagnostic system, read trouble codes, and take control of your repairs. Whether you’re dealing with a faulty oxygen sensor, EGR valve, or throttle position sensor, this method gives you the information you need to keep your classic truck running smoothly.

By following this guide, you’ve learned how to locate the DLC, trigger the self-test mode, interpret flash codes, and clear the check engine light—all using tools you probably already have at home. In 2026 and beyond, that kind of self-reliance is more valuable than ever.

So the next time that little orange light pops on, don’t ignore it. Grab a paperclip, follow these steps, and get back on the road with confidence.