This guide walks you through how to clear the check engine light on a 1994 Honda Accord by reading OBD-I trouble codes, diagnosing the issue, and safely resetting the system. Whether you’re a beginner or experienced DIYer, you’ll find clear, practical steps to get your Accord back on the road with confidence.

Key Takeaways

- Understand OBD-I System Basics: The 1994 Honda Accord uses an older OBD-I system, which requires manual code reading via the ECU connector—no scanner needed.

- Read Codes Manually: Use a paperclip or jumper wire to bridge the service connector and count the blinking patterns on the check engine light to identify trouble codes.

- Diagnose Before Clearing: Never clear the light without diagnosing the root cause—ignoring issues can lead to engine damage or emissions failures.

- Reset the ECU Properly: Disconnect the battery for 10–15 minutes to reset the ECU and clear stored codes after repairs are completed.

- Use Genuine or Quality Parts: When replacing sensors or components, opt for OEM or high-quality aftermarket parts to ensure long-term reliability.

- Test Drive After Reset: Always take a short test drive to confirm the light stays off and the vehicle runs smoothly.

- Know When to Seek Help: If the light returns or you’re unsure about repairs, consult a trusted mechanic—especially for complex issues like catalytic converter or ignition problems.

How to Clear Check Engine Light 94 Honda Accord Code: A Complete 2026 Guide

If you’re driving a classic 1994 Honda Accord and the dreaded check engine light has popped up, don’t panic. While modern cars use advanced OBD-II scanners to read and clear trouble codes, your ’94 Accord relies on an older but reliable OBD-I system. The good news? You can still diagnose and clear the check engine light yourself—no expensive tools or dealership visits required.

In this comprehensive guide, updated for 2026, we’ll walk you through every step of reading, diagnosing, and clearing the check engine light on your 1994 Honda Accord. Whether you’re a seasoned DIY mechanic or just getting started, this guide is designed to be simple, clear, and practical. You’ll learn how to interpret trouble codes using basic tools, fix common issues, and safely reset the engine control unit (ECU) to turn off that annoying light for good.

By the end of this guide, you’ll not only know how to clear the check engine light, but you’ll also understand what caused it in the first place—helping you avoid future problems and keep your Accord running smoothly for years to come.

Understanding the 1994 Honda Accord’s OBD-I System

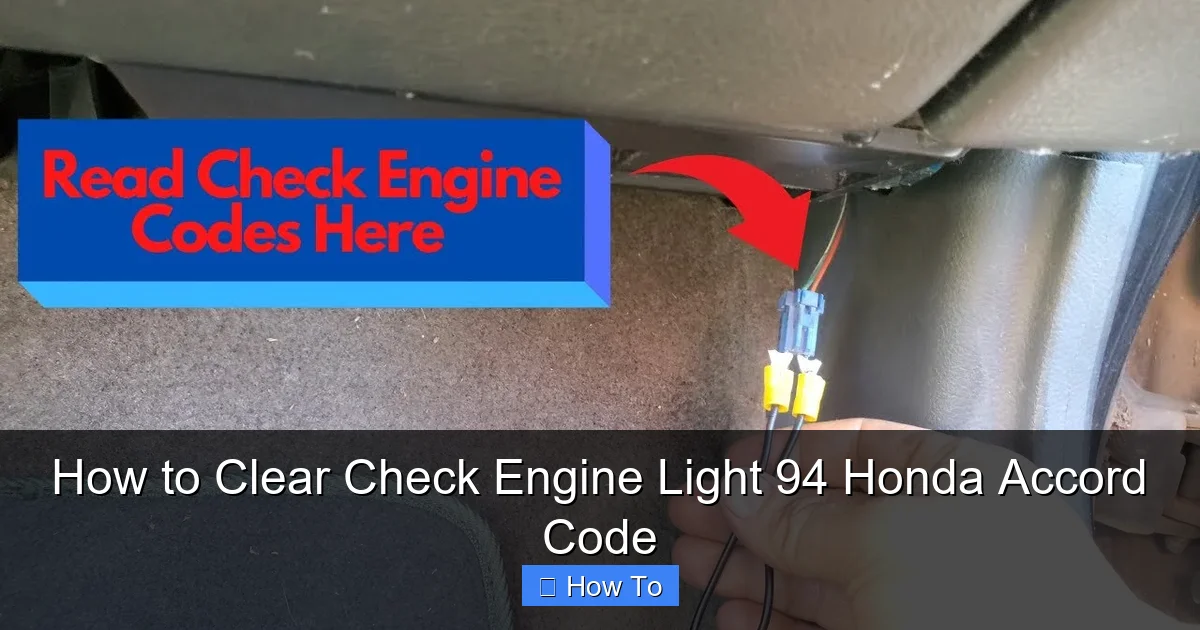

Visual guide about How to Clear Check Engine Light 94 Honda Accord Code

Image source: hondatheotherside.com

Before jumping into clearing the light, it’s important to understand how the 1994 Honda Accord’s onboard diagnostics system works. Unlike newer vehicles that use OBD-II (standardized since 1996), the 1994 Accord uses OBD-I—a manufacturer-specific system that predates universal diagnostic standards.

What Is OBD-I?

OBD-I stands for On-Board Diagnostics Generation I. It was the first attempt by automakers to monitor engine performance and emissions. While not as advanced as OBD-II, OBD-I systems like the one in your Accord can still detect malfunctions in critical components such as the oxygen sensor, ignition system, fuel injectors, and emissions controls.

The key difference? OBD-I doesn’t use a universal 16-pin connector or standardized trouble codes. Instead, Honda used a proprietary 2-pin service connector located under the dashboard, near the driver’s side kick panel. This means you can’t plug in a standard OBD-II scanner—you’ll need to read codes manually.

Why the Check Engine Light Comes On

The check engine light (also called the Malfunction Indicator Lamp or MIL) illuminates when the ECU detects a problem that could affect emissions or engine performance. Common triggers include:

– Faulty oxygen (O2) sensor

– Loose or damaged gas cap

– Misfiring spark plugs or ignition coils

– Clogged fuel injectors

– Failed EGR valve

– Vacuum leaks

– Catalytic converter issues

In some cases, the light may come on due to a temporary glitch—like a sudden drop in battery voltage or a loose connection. But more often than not, it’s signaling a real issue that needs attention.

Important Note: Don’t Just Clear the Light

One of the biggest mistakes drivers make is clearing the check engine light without diagnosing the underlying problem. While it’s tempting to just “make it go away,” doing so without fixing the root cause can lead to:

– Reduced fuel efficiency

– Increased emissions

– Engine damage over time

– Failed emissions tests (if applicable in your state)

Always diagnose the code first, then repair, then clear. We’ll show you exactly how to do that.

Step 1: Locate the Service Connector

The first step in reading trouble codes on your 1994 Honda Accord is finding the service connector. This small, 2-pin connector is your gateway to the ECU’s diagnostic data.

Where to Find It

The service connector is typically located under the dashboard on the driver’s side, near the left kick panel (the area where your left foot rests). It’s a small, black or gray plastic connector with two metal pins inside.

To access it:

1. Sit in the driver’s seat and look down near the floor.

2. You may need to remove a small plastic cover or panel—some models have a snap-on cover that pulls off easily.

3. The connector is usually labeled “Service Check Connector” or “SCS.” If not labeled, look for a 2-pin connector that’s not plugged into anything.

What You’ll Need

To read the codes, you’ll need:

– A paperclip, small jumper wire, or paperclip straightened out

– A flashlight (to see under the dash)

– A notepad and pen (to record the codes)

No special tools or scanners required—just basic household items.

Step 2: Read the Trouble Codes

Once you’ve located the service connector, it’s time to read the trouble codes. This process involves bridging the two pins to put the ECU into diagnostic mode, which will cause the check engine light to blink in a specific pattern.

How to Bridge the Connector

1. Turn the ignition key to the “ON” position (but do not start the engine). You should see the check engine light illuminate.

2. Insert one end of the paperclip or jumper wire into each of the two pins in the service connector. This creates a short circuit that tells the ECU to enter diagnostic mode.

3. Watch the check engine light on the dashboard. It will begin to blink in a series of long and short flashes.

Interpreting the Blink Patterns

The blinking pattern corresponds to a two-digit trouble code. Here’s how to decode it:

– A long blink = 10

– A short blink = 1

– A pause separates digits

For example:

– One long blink, then three short blinks = Code 13

– Two long blinks, then five short blinks = Code 25

The ECU will repeat the code sequence several times. Write down the code(s) you see.

Common 1994 Honda Accord Trouble Codes

Here are some of the most common OBD-I trouble codes for the 1994 Accord and what they mean:

– Code 1: Oxygen (O2) sensor circuit malfunction

– Code 3: Manifold Absolute Pressure (MAP) sensor issue

– Code 4: Crankshaft Position (CKP) sensor problem

– Code 7: Throttle Position (TPS) sensor out of range

– Code 9: Cylinder 1 misfire

– Code 13: Oxygen sensor heater circuit malfunction

– Code 17: Vehicle Speed Sensor (VSS) issue

Refer to your Honda service manual or a trusted online resource for a full list of codes. Websites like Honda-Tech.com or forums dedicated to older Accords are excellent sources.

What If No Codes Appear?

If the check engine light doesn’t blink after bridging the connector, it could mean:

– The ECU isn’t detecting any active faults (the light may have come on due to a past issue that’s now resolved)

– There’s a problem with the ECU itself

– The service connector is damaged or corroded

Try reinserting the jumper wire firmly. If still no response, inspect the connector for dirt, rust, or bent pins. Clean it with electrical contact cleaner if needed.

Step 3: Diagnose the Problem

Now that you’ve retrieved the trouble code, it’s time to figure out what’s actually wrong. Diagnosing the issue correctly is crucial—clearing the code without fixing the problem will only result in the light coming back on.

Start with the Most Likely Causes

Use the code as a starting point, but don’t assume it’s 100% accurate. OBD-I systems can sometimes misreport or generalize issues. For example, Code 1 (O2 sensor) could also be caused by a vacuum leak or exhaust leak near the sensor.

Here’s how to approach diagnosis:

1. Research the Code: Look up what the code means and what components are involved.

2. Inspect Visually: Check for obvious signs of damage—loose wires, cracked hoses, corroded connectors.

3. Test Components: Use a multimeter to test sensor resistance, voltage, or continuity if you’re comfortable doing so.

4. Check Related Systems: For example, a misfire (Code 9) could be due to bad spark plugs, ignition wires, or a failing coil.

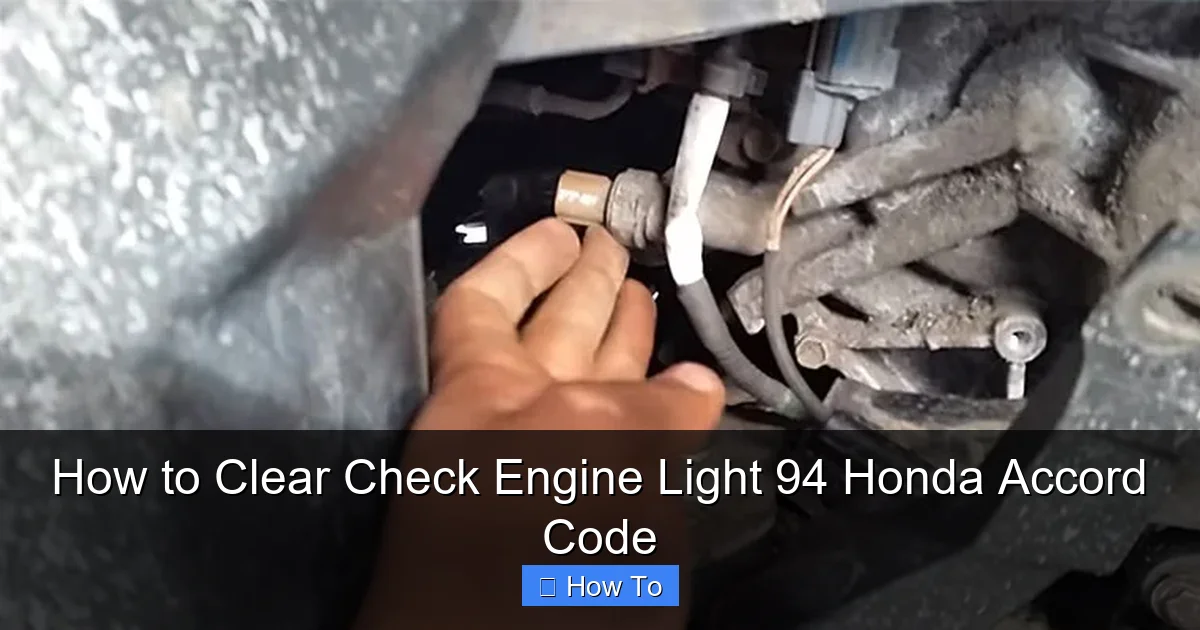

Example: Diagnosing Code 1 (O2 Sensor)

Let’s say you got Code 1. Here’s how to diagnose it:

– Locate the oxygen sensor—usually on the exhaust manifold or downpipe.

– Check the wiring harness for fraying, burns, or corrosion.

– Use a multimeter to test the sensor’s output voltage (should fluctuate between 0.1V and 0.9V at idle).

– If the sensor reads flatlined (e.g., stuck at 0.45V), it’s likely faulty.

But before replacing it, check for exhaust leaks upstream of the sensor—even a small leak can trick the ECU into thinking the O2 sensor is bad.

When to Use a Multimeter

A basic digital multimeter is a valuable tool for diagnosing electrical issues. You can use it to:

– Test battery voltage (should be ~12.6V off, ~14V running)

– Check sensor resistance (refer to service manual specs)

– Verify continuity in wires and fuses

If you don’t own a multimeter, they’re inexpensive and widely available at auto parts stores or online.

Common Fixes for Frequent Codes

Here are quick fixes for some of the most common 1994 Accord trouble codes:

– Code 1 (O2 Sensor): Replace the sensor if faulty. Use a Honda-compatible sensor (preferably OEM or Denso).

– Code 3 (MAP Sensor): Clean the sensor with electronics cleaner or replace if damaged.

– Code 7 (TPS): Adjust or replace the throttle position sensor. Ensure the throttle cable isn’t too tight.

– Code 9 (Misfire): Replace spark plugs, wires, and distributor cap/rotor. Check for carbon tracking.

Always disconnect the battery before working on electrical components to avoid short circuits.

Step 4: Repair the Issue

Once you’ve identified the problem, it’s time to fix it. The repair process will vary depending on the code, but here are some general guidelines.

Use Quality Parts

When replacing sensors or components, avoid cheap, no-name parts. They may fail quickly or cause inaccurate readings. Stick with:

– OEM (Original Equipment Manufacturer) parts

– Reputable aftermarket brands like Denso, Bosch, or NGK

For example, Denso makes excellent O2 sensors that are often used as OEM replacements in Hondas.

Follow Proper Procedures

Always follow the factory service manual for torque specs, routing, and installation steps. For instance:

– When replacing spark plugs, use a torque wrench to avoid over-tightening.

– When installing a new O2 sensor, apply anti-seize compound to the threads (but not on the sensor tip).

– Reconnect all electrical connectors securely—loose connections can cause intermittent codes.

Test as You Go

After making a repair, reconnect the battery and turn the ignition to “ON” (don’t start the engine). Check that all warning lights behave normally. Then start the engine and listen for unusual noises or performance issues.

If the repair was successful, the check engine light may stay off—but don’t assume it’s cleared yet. We’ll cover the proper reset procedure next.

Step 5: Clear the Check Engine Light

Now that the issue is fixed, it’s time to clear the check engine light and reset the ECU. On the 1994 Accord, this is done by disconnecting the battery—a simple but effective method.

How to Reset the ECU

1. Turn off the engine and remove the key.

2. Open the hood and locate the battery.

3. Use a wrench to loosen the negative (-) battery terminal clamp.

4. Disconnect the negative cable from the battery terminal.

5. Wait 10 to 15 minutes. This allows the ECU’s volatile memory to fully discharge.

6. Reconnect the negative cable and tighten the clamp securely.

Why Wait 10–15 Minutes?

The ECU stores trouble codes and learned fuel trim values in its memory. Disconnecting the battery cuts power to this memory. Waiting at least 10 minutes ensures all capacitors discharge and the system fully resets.

Alternative Method: Fuse Pull (Less Reliable)

Some older guides suggest pulling the ECU fuse instead of disconnecting the battery. While this can work, it’s less reliable because not all fuses power the ECU directly. The battery method is more thorough and recommended.

What Happens After Reset?

After reconnecting the battery:

– Turn the ignition to “ON.” The check engine light should illuminate briefly, then turn off.

– Start the engine. The light should stay off if the problem is resolved.

– If the light comes back on immediately, the issue may still exist—or the ECU hasn’t fully reset.

Step 6: Test Drive and Monitor

Clearing the light is only half the battle. You need to confirm the repair worked and the vehicle is running properly.

Take a Short Test Drive

Drive the car for 10–15 minutes, including:

– City driving (stop-and-go traffic)

– Highway speeds (if safe and legal)

– Idling for a few minutes

This allows the ECU to relearn fuel trims and monitor all systems under real-world conditions.

Watch for Warning Signs

During and after the drive, pay attention to:

– Is the check engine light still off?

– Does the engine run smoothly?

– Any unusual noises, vibrations, or smells?

– Is fuel economy back to normal?

If everything looks good, congratulations—you’ve successfully cleared the check engine light!

What If the Light Comes Back?

If the light returns after a few days or miles, it means:

– The original problem wasn’t fully fixed

– A new issue has developed

– The ECU detected an intermittent fault

Re-read the codes and re-diagnose. Sometimes, a sensor may test fine at rest but fail under load.

Troubleshooting Common Issues

Even with careful steps, you might run into problems. Here’s how to handle common scenarios.

The Light Won’t Clear After Reset

Possible causes:

– The underlying issue wasn’t fixed

– The ECU needs more drive cycles to confirm the repair

– There’s a wiring or grounding issue

Solution: Re-check your repair. Use a multimeter to verify sensor operation. Ensure all grounds are clean and tight.

Multiple Codes Appear

Sometimes, one problem triggers multiple codes. For example, a bad O2 sensor can cause misfires and fuel trim issues.

Solution: Address the primary code first (usually the lowest number). Clear the codes, then recheck. Secondary codes may disappear on their own.

Battery Dies Frequently After Reset

Disconnecting the battery can reset the radio, clock, and power windows. In rare cases, it may also affect the alternator or charging system.

Solution: Drive the car for 20–30 minutes to allow the alternator to recharge the battery fully. If the battery continues to die, have it tested.

Service Connector Is Hard to Reach

Some Accords have tight spaces under the dash.

Solution: Use a flexible jumper wire or ask a friend to hold the wire while you watch the light. Alternatively, remove the lower dash panel for better access.

Preventing Future Check Engine Lights

Now that your Accord is running clean, take steps to avoid future issues.

Regular Maintenance

Follow the factory maintenance schedule:

– Replace spark plugs every 30,000–50,000 miles

– Change air and fuel filters regularly

– Inspect belts and hoses annually

– Use high-quality fuel and oil

Check the Gas Cap

A loose or damaged gas cap is a common cause of check engine lights (even on older cars). Make sure it clicks when tightened.

Listen to Your Car

Unusual sounds, smells, or performance changes are early warning signs. Address them before they trigger a code.

Conclusion

Clearing the check engine light on a 1994 Honda Accord doesn’t require a mechanic or expensive tools. With a paperclip, a little patience, and this guide, you can read trouble codes, diagnose issues, and reset the ECU yourself—all from your driveway.

Remember: the key to success is diagnosing the problem before clearing the light. Ignoring the root cause can lead to bigger, costlier repairs down the road. By following the steps in this guide, you’ll not only turn off that annoying light but also gain confidence in maintaining your classic Accord.

Whether you’re keeping your ’94 Accord on the road for sentimental reasons or as a reliable daily driver, understanding its OBD-I system empowers you to take control of its health. So grab that paperclip, roll up your sleeves, and get back to driving with peace of mind.

Your Accord—and your wallet—will thank you.