Discover how to determine check engine light no reader using built-in vehicle diagnostics, visual inspections, and basic tools. This guide helps you identify common engine problems without needing an OBD2 scanner, saving you time and repair costs.

Key Takeaways

- Use the key-on-engine-off (KOEO) method: Many older vehicles let you read check engine light codes by turning the ignition on and off in a specific sequence to flash trouble codes.

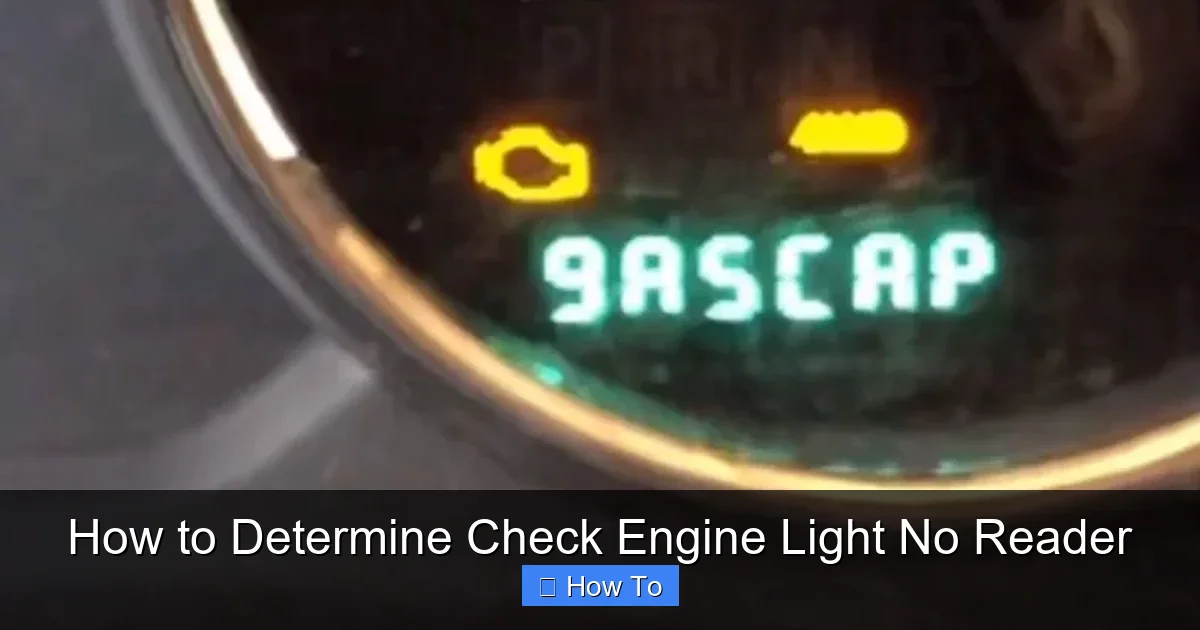

- Check the gas cap first: A loose or damaged gas cap is one of the most common causes of a check engine light and can be fixed in seconds.

- Listen for unusual engine sounds: Knocking, pinging, or rough idling can point to ignition, fuel, or sensor issues even without a code reader.

- Inspect engine components visually: Look for cracked hoses, worn belts, or leaking fluids that may trigger the light.

- Monitor driving behavior: Poor acceleration, stalling, or reduced fuel economy often accompany check engine light issues.

- Use a multimeter for basic electrical tests: Test battery voltage, alternator output, and sensor resistance to narrow down problems.

- Know when to seek professional help: If the light flashes or symptoms persist, visit a mechanic to prevent engine damage.

How to Determine Check Engine Light No Reader

Seeing the check engine light come on can be stressful—especially if you don’t have an OBD2 scanner or code reader on hand. But don’t panic! You can still figure out what’s going on with your vehicle using simple, practical methods. This guide will walk you through how to determine check engine light no reader, using tools you likely already have and techniques that don’t require advanced technical skills.

Whether you’re driving an older car without modern diagnostics or just left your scanner at home, these steps will help you identify common issues, understand what the light might mean, and decide whether you can fix it yourself or need professional help.

Step 1: Don’t Ignore the Light

The first rule when the check engine light comes on is: don’t ignore it. While it might seem harmless, this warning light indicates that your vehicle’s onboard computer has detected a problem with the engine, emissions system, or related components.

There are two types of check engine lights:

– Solid (steady) light: Usually means a minor issue, like a loose gas cap or a sensor glitch.

– Flashing light: Indicates a serious problem, such as a misfire that could damage the catalytic converter. If the light is flashing, pull over safely and avoid driving until the issue is resolved.

Even if the light is steady, it’s important to investigate. Ignoring it could lead to reduced fuel efficiency, poor performance, or costly repairs down the road.

Step 2: Check the Gas Cap

One of the most common—and easiest—fixes for a check engine light is the gas cap. A loose, cracked, or missing gas cap can allow fuel vapors to escape, triggering the evaporative emissions system (EVAP) monitor.

How to check:

- Turn off the engine and locate the gas cap (usually on the side of the car).

- Unscrew it and inspect the rubber seal for cracks or damage.

- Reinstall it firmly until you hear it click 2–3 times.

- Drive for a few days to see if the light turns off.

In many cases, tightening the gas cap resolves the issue. If the light returns, the cap may need replacement—a cheap and easy fix.

Step 3: Use the Key-On-Engine-Off (KOEO) Method

If your vehicle is from the 1990s or earlier, it may not have a standard OBD2 port, but it could still allow you to read trouble codes using the check engine light itself. This is called the “flash code” method.

Steps to read flash codes:

- Turn the ignition to the “ON” position (but don’t start the engine).

- Locate the diagnostic connector under the dashboard (often near the fuse box).

- Use a paperclip or jumper wire to connect two specific pins (refer to your vehicle’s service manual for the correct pins).

- Watch the check engine light—it will begin to flash in a pattern.

- Count the flashes: long flashes represent tens, short flashes represent ones. For example, two long and three short flashes mean code 23.

Once you have the code, look it up in a repair manual or online database to understand the issue. This method works on many older GM, Ford, and Chrysler vehicles.

Step 4: Listen and Feel for Symptoms

Even without a code reader, your senses can help you determine what’s wrong. Pay attention to how your car behaves.

Common symptoms and what they might mean:

- Rough idling or stalling: Could indicate a faulty spark plug, ignition coil, or mass airflow (MAF) sensor.

- Hesitation or poor acceleration: Often linked to fuel delivery issues, such as a clogged fuel filter or failing fuel pump.

- Knocking or pinging sounds: May point to low-octane fuel, carbon buildup, or ignition timing problems.

- Reduced fuel economy: Could be caused by a bad oxygen sensor, dirty air filter, or tire pressure issues.

- Exhaust smoke: Blue smoke = burning oil; white smoke = coolant leak; black smoke = rich fuel mixture.

Keep a mental or written note of these symptoms. They’ll help you or a mechanic narrow down the cause.

Step 5: Perform a Visual Inspection

A quick look under the hood can reveal a lot. Many check engine light issues stem from visible problems.

What to inspect:

- Engine belts: Look for cracks, fraying, or looseness. A slipping belt can affect the alternator or water pump.

- Hoses: Check for leaks, bulges, or disconnected vacuum lines. A cracked vacuum hose can cause a lean fuel mixture.

- Air filter: A dirty or clogged air filter restricts airflow and can trigger the light.

- Spark plug wires: Look for burns, cracks, or corrosion. Damaged wires can cause misfires.

- Fluid levels: Check oil, coolant, and transmission fluid. Low levels can cause engine stress and trigger warnings.

If you find something obvious—like a disconnected hose or low oil—fix it and see if the light goes off after a few drives.

Step 6: Use a Multimeter for Basic Electrical Tests

A multimeter is an affordable tool (under $20) that can help you test electrical components. You don’t need to be an expert to use it for basic checks.

Common tests:

- Battery voltage: With the engine off, a healthy battery should read 12.4–12.7 volts. Below 12.2 volts may indicate a weak battery.

- Alternator output: Start the engine and check voltage at the battery terminals. It should read 13.8–14.8 volts. Lower readings suggest alternator issues.

- Oxygen sensor resistance: Disconnect the sensor and test resistance across its terminals (refer to the service manual for specs). Out-of-range values may mean a faulty sensor.

These tests can help confirm or rule out electrical problems without needing a scanner.

Step 7: Monitor the Light Over Time

Sometimes, the check engine light comes on temporarily due to a minor glitch—like a sudden drop in fuel quality or a brief sensor error.

What to do:

- Drive normally for 3–5 days.

- If the light turns off on its own, the issue may have been temporary.

- If it returns, the problem is likely persistent and needs attention.

Keep track of when the light appears—after refueling, in cold weather, or during acceleration. This pattern can help identify the cause.

Step 8: Know When to See a Mechanic

While many check engine light issues can be diagnosed without a reader, some problems require professional tools and expertise.

Seek help if:

- The light is flashing.

- The car is running poorly, overheating, or making loud noises.

- You’ve tried basic fixes and the light remains on.

- You’re unsure about performing electrical or mechanical repairs.

A mechanic can use a professional scanner to read detailed codes, perform advanced diagnostics, and ensure your vehicle is safe to drive.

Troubleshooting Common Issues Without a Reader

Here are a few real-world examples of how to determine check engine light no reader based on symptoms:

Example 1: Light came on after filling up gas

Check the gas cap first. If it’s loose or damaged, tighten or replace it. Drive for a few days. If the light stays off, problem solved.

Visual guide about How to Determine Check Engine Light No Reader

Image source: jeepgenius.com

Example 2: Car idles roughly and light is on

Inspect spark plugs and wires. Look for wear or carbon buildup. Replace if necessary. Also check the air filter and vacuum hoses.

Example 3: Light comes on during acceleration

This could indicate a fuel delivery issue. Check the fuel filter and listen for a weak fuel pump (a humming sound from the rear of the car when turning the key to “ON”).

Example 4: Light is on but car runs fine

It might be a minor sensor issue, like a faulty oxygen sensor. Use a multimeter to test it, or visit a mechanic for confirmation.

Conclusion

You don’t need a code reader to figure out why your check engine light is on. By using simple methods like checking the gas cap, listening for symptoms, performing visual inspections, and using basic tools like a multimeter, you can often determine the cause and decide on the next steps.

Remember: a steady light is usually less urgent than a flashing one, but it still deserves attention. Use the key-on-engine-off method if your car supports it, and don’t hesitate to seek professional help when needed.

With these tips, you’ll be better prepared to handle check engine light issues—no scanner required. Stay informed, stay safe, and keep your car running smoothly.