This guide teaches how to diagnose semi truck engine lights using simple steps and the right tools. You’ll learn to read warning signs, use diagnostic tools, and decide when to call a mechanic.

Key Takeaways

- Engine lights signal problems: The check engine light or other dashboard warnings indicate issues that need attention to avoid costly repairs.

- Use an OBD2 scanner: A heavy-duty OBD2 scanner reads fault codes and helps pinpoint the source of the problem.

- Check common causes first: Low DEF fluid, clogged filters, or loose gas caps can trigger lights and are easy to fix.

- Know your truck’s dashboard symbols: Different lights mean different things—learn what each one represents.

- Don’t ignore warning lights: Delaying repairs can lead to engine damage, breakdowns, or safety risks.

- Keep maintenance records: Tracking past issues helps spot patterns and speeds up future diagnoses.

- When in doubt, consult a pro: Some problems require specialized tools or expertise—don’t risk further damage.

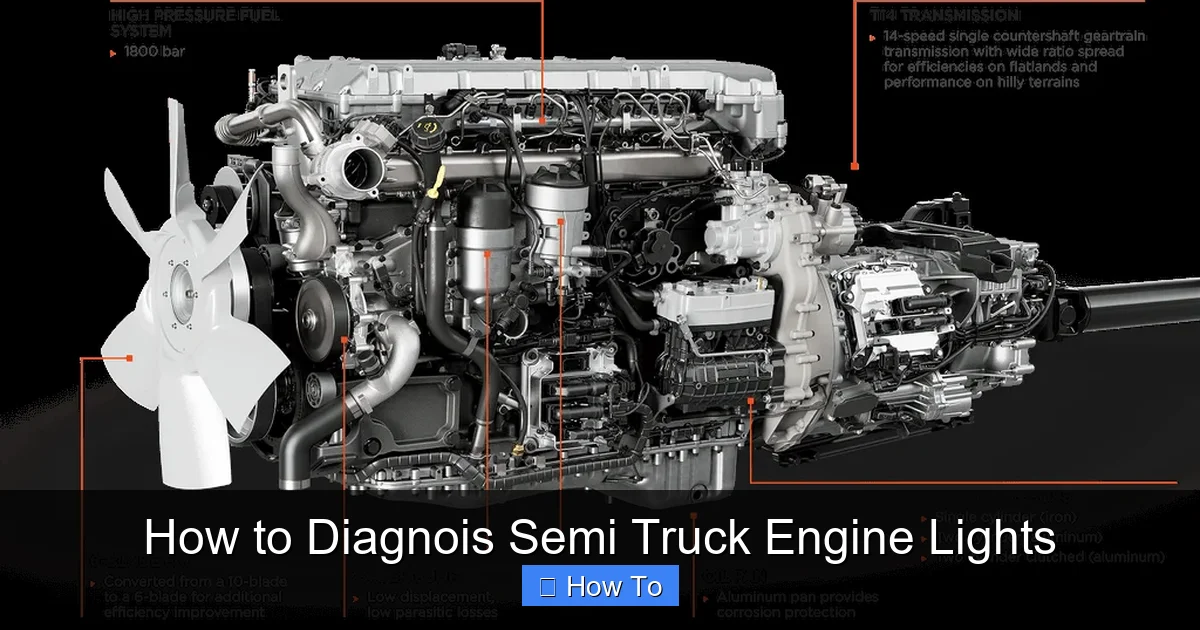

How to Diagnose Semi Truck Engine Lights: A Complete Guide

If you drive a semi truck, you know that dashboard warning lights aren’t just annoying—they’re your truck’s way of saying, “Hey, something’s wrong!” Whether it’s the check engine light, DEF warning, or a temperature alert, ignoring these signals can lead to expensive repairs or even roadside breakdowns. The good news? You don’t need to be a mechanic to figure out what’s going on. With the right tools and a little know-how, you can diagnose semi truck engine lights quickly and confidently.

In this guide, we’ll walk you through a step-by-step process to identify, understand, and respond to engine warning lights. You’ll learn how to use diagnostic tools, interpret common symbols, and decide whether to fix the issue yourself or call in a professional. By the end, you’ll feel more in control of your truck’s health and save time and money on repairs.

Step 1: Stay Calm and Pull Over Safely

Visual guide about How to Diagnois Semi Truck Engine Lights

Image source: thumbs.dreamstime.com

When a warning light pops up, your first instinct might be to panic. Don’t. Most engine lights don’t mean immediate danger—but they do mean you need to act.

Assess the Situation

Look at the light. Is it flashing or steady? A flashing check engine light usually means a serious problem, like a misfire that could damage the catalytic converter. A steady light often indicates a less urgent issue, such as a sensor malfunction.

If the light is flashing, or if you notice strange noises, smoke, or a loss of power, pull over safely as soon as possible. Turn off the engine and assess.

Check for Obvious Issues

Before diving into diagnostics, do a quick visual check:

- Is the gas cap loose or missing?

- Are there any visible leaks under the truck?

- Is the coolant level low?

- Is the DEF tank empty?

Sometimes, the fix is as simple as tightening a cap or topping off fluid.

Step 2: Identify the Warning Light

Not all dashboard lights are the same. Knowing what each one means is key to diagnosing the problem.

Common Semi Truck Warning Lights

- Check Engine Light (CEL): Indicates a problem with the engine or emissions system. Could be anything from a faulty oxygen sensor to a serious engine misfire.

- DEF Warning Light: Means your Diesel Exhaust Fluid is low. Top it off to avoid reduced power or shutdown.

- Engine Temperature Light: Signals overheating. Stop immediately to prevent engine damage.

- Oil Pressure Light: Low oil pressure can destroy your engine. Pull over and shut down right away.

- Air Pressure Warning: Indicates low air pressure in the braking system. This is critical—stop driving until fixed.

- Glow Plug Light: Common in cold weather. Usually turns off after the engine warms up.

Refer to your truck’s owner manual for a full list of symbols and their meanings.

Step 3: Use an OBD2 Scanner to Read Fault Codes

The most effective way to diagnose semi truck engine lights is by reading the diagnostic trouble codes (DTCs) stored in the truck’s computer.

Get the Right Scanner

You’ll need a heavy-duty OBD2 scanner designed for commercial trucks. Consumer-grade scanners won’t work on most semi trucks because they use different protocols (like J1939 instead of standard OBD2).

Popular options include:

- Bosch Automotive Test Tools

- Launch Tech CRP129X

- Autel MaxiCOM MK808TS

These scanners plug into the OBD2 port (usually under the dashboard) and communicate with the engine control unit (ECU).

Connect and Scan

- Turn the ignition to the “on” position (don’t start the engine).

- Plug the scanner into the OBD2 port.

- Follow the on-screen prompts to scan for codes.

- Write down all the codes displayed (e.g., P0401, SPN 5246).

Each code corresponds to a specific issue. For example, P0401 means “Exhaust Gas Recirculation Flow Insufficient,” which could be caused by a clogged EGR valve.

Look Up the Codes

Use the scanner’s built-in database or search online for the meaning of each code. Websites like OBD-Codes.com or manufacturer forums can help. Some scanners even provide repair suggestions.

Step 4: Investigate Common Causes

Once you have the codes, it’s time to dig deeper. Many engine light issues stem from a few common problems.

Low or Contaminated DEF Fluid

Modern diesel trucks use DEF to reduce emissions. If the DEF tank is low or the fluid is contaminated, the truck may go into “limp mode” or shut down.

Solution: Top off with fresh DEF. Use only certified DEF (look for the API or ISO 22241 label). Never use water or homemade substitutes.

Clogged or Faulty Sensors

Sensors like the oxygen sensor, mass airflow (MAF) sensor, or NOx sensor can fail or get dirty, triggering false alarms.

Solution: Clean or replace the sensor. For example, a dirty MAF sensor can cause poor fuel economy and a check engine light. Use MAF cleaner spray—never touch the sensor wires.

Air or Fuel Filter Issues

A clogged air filter restricts airflow, while a dirty fuel filter reduces fuel delivery. Both can cause performance issues and warning lights.

Solution: Replace filters according to the maintenance schedule. Check for signs of dirt, damage, or moisture.

Loose or Damaged Wiring

Vibration and weather can loosen electrical connections. A loose wire to a sensor can cause intermittent faults.

Solution: Inspect wiring harnesses near the engine. Look for frayed wires, corrosion, or loose plugs. Reconnect or repair as needed.

Step 5: Clear the Codes and Test Drive

After addressing the issue, it’s time to see if the fix worked.

Clear the Fault Codes

Use your OBD2 scanner to clear the stored codes. This turns off the warning light—if the problem is truly fixed.

Take a Test Drive

Drive the truck for at least 10–15 minutes, including highway speeds. This allows the ECU to run self-checks and confirm the issue is resolved.

If the light comes back on, the problem may be more complex or not fully fixed. Re-scan for new codes.

Step 6: Know When to Call a Mechanic

Not every issue can—or should—be fixed by a driver. Some problems require specialized tools, software, or expertise.

Signs You Need Professional Help

- The check engine light is flashing.

- You’re getting multiple or repeated fault codes.

- The truck is losing power, overheating, or making loud noises.

- You’re unsure about the repair or lack the right tools.

Modern semi trucks have complex computer systems. Attempting advanced repairs without training can cause more damage.

Find a Trusted Shop

Look for a repair shop with experience in your truck’s make and model (e.g., Freightliner, Peterbilt, Volvo). Ask about their diagnostic capabilities and whether they use OEM (original equipment manufacturer) tools.

Troubleshooting Tips

Even with the best tools, diagnosing engine lights can be tricky. Here are some practical tips:

- Keep a log: Record when lights appear, what codes you get, and what you did to fix them. This helps spot patterns.

- Update your scanner: Manufacturers release software updates that improve code reading and accuracy.

- Check for recalls: Some engine light issues are due to known defects. Visit the NHTSA website or contact your dealer.

- Use quality parts: Cheap sensors or fluids can fail quickly and trigger false alarms.

- Don’t ignore intermittent lights: A light that comes and goes may indicate a wiring issue or sensor on the verge of failure.

Conclusion

Diagnosing semi truck engine lights doesn’t have to be overwhelming. By staying calm, identifying the warning, using an OBD2 scanner, and investigating common causes, you can often resolve issues quickly and safely. Remember: the goal isn’t to fix everything yourself—it’s to understand what’s happening and make smart decisions about repairs.

Regular maintenance, quality parts, and a good diagnostic tool go a long way in keeping your truck running smoothly. And when in doubt, don’t hesitate to call a professional. Your safety, your truck, and your bottom line will thank you.

With this guide, you’re now equipped to handle engine warning lights like a pro. Safe driving!