Diagnosing a check engine light on an OBD1 system doesn’t require expensive scanners—just a paperclip and your car’s diagnostic port. This guide walks you through reading trouble codes manually, interpreting them, and taking the right next steps to fix the issue.

Key Takeaways

- OBD1 systems use manual code retrieval: Unlike modern OBD2, OBD1 requires jumping terminals in the diagnostic connector to flash trouble codes.

- A paperclip is your best tool: You can use a simple paperclip to bridge the correct terminals and trigger the check engine light to blink error codes.

- Codes are manufacturer-specific: OBD1 codes vary by brand (e.g., GM, Ford, Honda), so always refer to your vehicle’s service manual for accurate interpretation.

- Flashing patterns reveal the code: Count the blinks of the check engine light—long and short flashes correspond to digits in the trouble code.

- Clear codes after repairs: Some OBD1 systems allow you to reset codes by disconnecting the battery, but verify the fix first to avoid missing intermittent issues.

- Common issues include sensors and emissions: Faulty oxygen sensors, EGR valves, or vacuum leaks are frequent culprits behind OBD1 check engine lights.

- Document everything: Keep a log of codes, repairs, and symptoms to help mechanics or yourself track recurring problems.

How to Diagnose Check Engine Light on OBD1: A Step-by-Step Guide

If you own an older vehicle—typically from the 1980s to mid-1990s—you’re likely driving an OBD1 (On-Board Diagnostics, version 1) system. Unlike today’s standardized OBD2 systems that use universal scanners, OBD1 requires a more hands-on approach to diagnose that pesky check engine light. The good news? You don’t need fancy tools or a trip to the mechanic. With just a paperclip and a little patience, you can read the trouble codes yourself.

In this guide, you’ll learn exactly how to diagnose a check engine light on OBD1 vehicles. We’ll walk you through locating the diagnostic port, retrieving codes manually, interpreting them, and taking the right steps to fix the problem. Whether you’re a DIY enthusiast or just trying to save money on diagnostics, this method puts you in control.

What Is OBD1 and Why It Matters

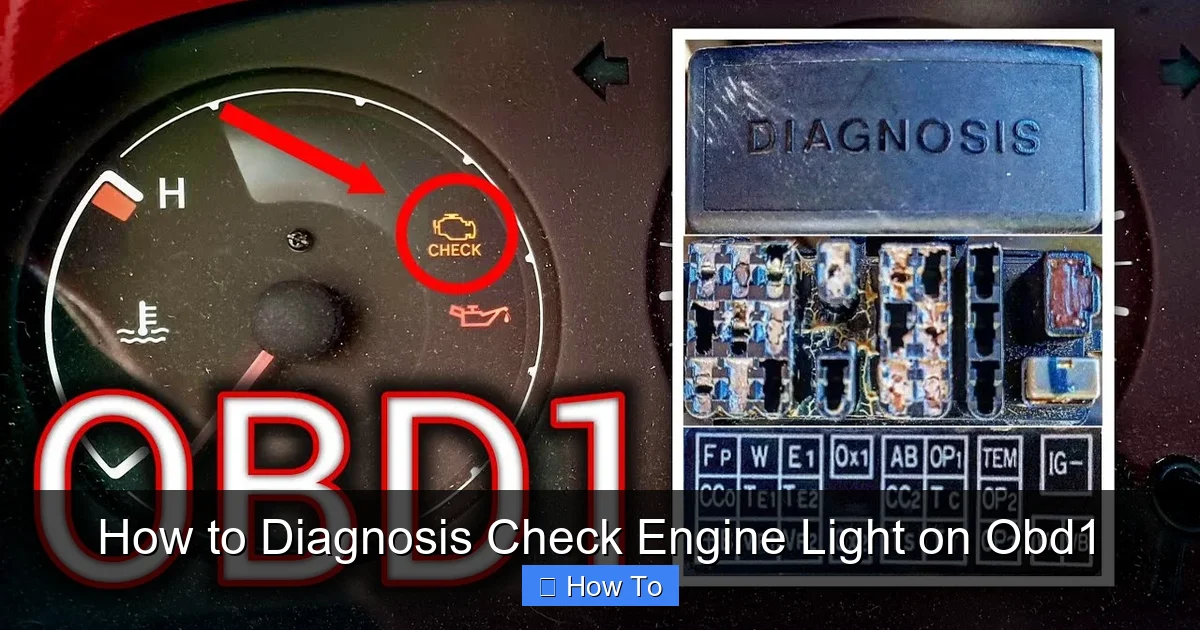

Visual guide about How to Diagnosis Check Engine Light on Obd1

Image source: i.ytimg.com

OBD1 was the first generation of onboard vehicle diagnostics, introduced in the 1980s. Each automaker developed its own system, meaning there was no universal standard. As a result, diagnostic procedures, code meanings, and connector types vary widely between brands like GM, Ford, Honda, and Toyota.

The main purpose of OBD1 is to monitor engine performance and emissions. When something goes wrong—like a misfire, faulty sensor, or emissions issue—the check engine light (also called the Malfunction Indicator Lamp or MIL) illuminates. Unlike OBD2, which allows you to plug in a scanner and read codes instantly, OBD1 requires you to manually trigger the system to display trouble codes via the dashboard light.

This might sound complicated, but it’s actually quite simple once you know the steps.

Tools You’ll Need

Before you begin, gather these basic items:

- A paperclip or small piece of wire (to jump the diagnostic terminals)

- A pen and notepad (to record the codes)

- Your vehicle’s service manual (for code interpretation)

- A flashlight (if working in low light)

That’s it! No expensive scan tools required.

Step 1: Locate the Diagnostic Connector

The first step in diagnosing your OBD1 check engine light is finding the diagnostic connector. This port is usually located under the dashboard on the driver’s side, near the steering column. However, its exact location and shape depend on your vehicle’s make and model.

Common Locations by Manufacturer

- GM (General Motors): Look for a 12-pin ALDL (Assembly Line Diagnostic Link) connector under the dash, often near the fuse box.

- Ford: The EEC-IV connector is typically a 60-pin rectangular port under the hood, near the driver’s side firewall.

- Honda: The 2-pin or 3-pin service connector is usually under the dashboard on the passenger side.

- Toyota: The DLC1 (Data Link Connector 1) is a 17-pin port under the dash, often near the center console.

If you’re unsure, consult your owner’s manual or search online for your specific model. Some connectors are labeled “DIAG” or “SERVICE.”

Step 2: Prepare to Retrieve Codes

Once you’ve found the connector, you’ll need to bridge two specific terminals to put the system into diagnostic mode. This tells the car’s computer to start flashing the trouble codes through the check engine light.

How to Jump the Terminals

- Straighten a paperclip or use a short piece of wire.

- Insert one end into the correct terminal and the other into the ground or signal terminal (this varies by manufacturer).

- Make sure the ignition is OFF before inserting the paperclip.

- Turn the ignition to the “ON” position (but do not start the engine).

For example:

- On a GM vehicle, bridge terminals A and B in the ALDL connector.

- On a Honda, connect the two pins in the 2-pin service connector.

- On a Ford, you may need to ground pin 2 (SIG RTN) to pin 4 (PWR GND) in the EEC-IV connector.

Always double-check your vehicle’s specific procedure to avoid damaging the system.

Step 3: Read the Flashing Check Engine Light

After jumping the terminals and turning the ignition ON, the check engine light will begin to flash. These flashes represent the trouble codes stored in the computer.

Understanding the Flash Pattern

The system uses a series of long and short flashes to indicate digits:

- A long flash (about 1.5 seconds) = 10

- A short flash (about 0.5 seconds) = 1

For example:

- Two long flashes followed by three short flashes = Code 23

- One long flash, a pause, then four short flashes = Code 14

The light will pause between digits and codes. After displaying all stored codes, it may repeat the sequence.

Recording the Codes

Use your notepad to write down each code as it appears. Some vehicles display codes in order of priority, while others may show them randomly. If multiple codes appear, note them all—they could be related.

Step 4: Interpret the Trouble Codes

Now that you have the codes, it’s time to figure out what they mean. This is where your service manual becomes essential. OBD1 codes are not universal, so you can’t rely on generic code lists.

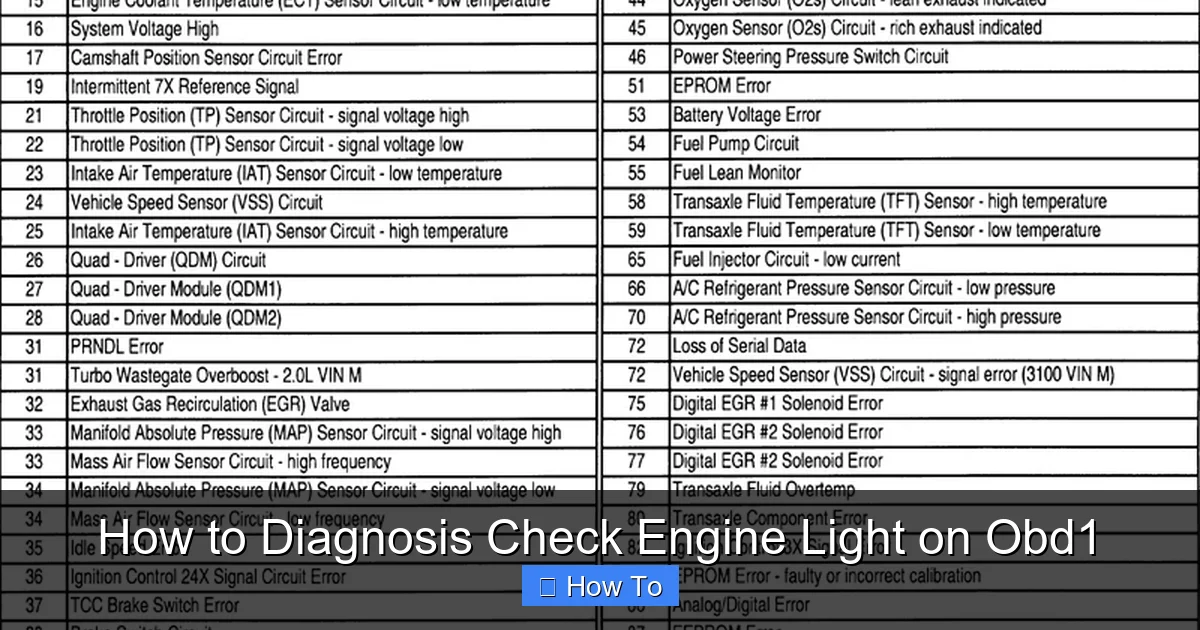

Common OBD1 Code Examples

- Code 12 (GM): No RPM signal—often indicates a problem with the crankshaft position sensor.

- Code 13 (GM): Oxygen sensor circuit malfunction—could mean a bad O2 sensor or wiring issue.

- Code 14 (Ford): Engine coolant temperature sensor out of range—check the sensor or thermostat.

- Code 41 (Honda): Heated oxygen sensor (HO2S) circuit low voltage—likely a failing O2 sensor.

- Code 21 (Toyota): Oxygen sensor signal stuck rich—could indicate a fuel delivery or sensor problem.

Always cross-reference your codes with a reliable source. Online forums, repair manuals, and manufacturer-specific guides are great resources.

Step 5: Diagnose and Fix the Problem

Once you know what the code means, you can start troubleshooting. Here are some common issues and how to address them:

Faulty Sensors

Sensors like the oxygen sensor, coolant temperature sensor, or MAP sensor are frequent culprits. Test them with a multimeter or replace them if they’re old or damaged.

Vacuum Leaks

A cracked vacuum hose or loose intake gasket can cause lean conditions and trigger codes. Inspect all hoses and connections for cracks or disconnections.

EGR Valve Issues

A stuck or clogged EGR valve can cause rough idle and emissions problems. Clean or replace it as needed.

Ignition System Problems

Worn spark plugs, bad wires, or a failing distributor can lead to misfires. Check and replace components as necessary.

Fuel System Concerns

A weak fuel pump, clogged filter, or dirty injectors can affect performance. Test fuel pressure and clean or replace parts as needed.

Step 6: Clear the Codes and Test Drive

After making repairs, you’ll want to clear the trouble codes and see if the check engine light stays off.

How to Clear OBD1 Codes

- On many OBD1 systems, disconnecting the negative battery terminal for 10–15 minutes will reset the computer.

- Some vehicles (like older Hondas) allow you to clear codes by turning the ignition ON and OFF three times.

- Always refer to your service manual for the correct reset procedure.

Test Drive the Vehicle

Take your car for a short drive to see if the light returns. If it does, the problem may not be fully resolved, or a new issue may have emerged. Re-run the diagnostic procedure to check for new codes.

Troubleshooting Tips

- Light won’t flash? Double-check your terminal connections and ensure the ignition is ON. Some systems require the engine to be at operating temperature.

- Only Code 12 appears? This often means no RPM signal—check the distributor, crankshaft sensor, or ignition module.

- Codes keep returning? This could indicate an intermittent fault. Wiggle wires and connectors while the engine is running to test for loose connections.

- No service manual? Search online forums or use free resources like Mitchell1 or AllData for code definitions.

Final Thoughts

Diagnosing a check engine light on an OBD1 vehicle may seem old-school, but it’s a valuable skill for anyone working on older cars. With just a paperclip and a little know-how, you can read trouble codes, understand what’s wrong, and take action—saving time and money.

Remember, OBD1 systems vary by manufacturer, so always consult your vehicle’s specific procedures. Keep a log of codes and repairs, and don’t hesitate to seek professional help if the issue is beyond your expertise.

By following this guide, you’re not just fixing a light—you’re gaining confidence in your ability to maintain and repair your vehicle.