If your 2007 Ford F-150 engine light is on, don’t panic—this guide walks you through diagnosing the issue, fixing common problems, and resetting the light. Save time and money by troubleshooting at home with simple tools and expert tips.

Key Takeaways

- Read the trouble code first: Use an OBD2 scanner to identify the specific issue triggering the engine light. This prevents guesswork and saves time.

- Common culprits include oxygen sensors, spark plugs, and gas caps: These low-cost fixes resolve over 60% of check engine light cases in older F-150s.

- Inspect the gas cap: A loose or damaged cap is a frequent cause of EVAP system codes and is one of the easiest fixes.

- Replace worn spark plugs and ignition coils: Misfires are common in 2007 F-150s with high mileage and can trigger the engine light.

- Check the mass airflow (MAF) sensor: Dirt or damage here can cause poor fuel economy and performance issues.

- Clear the code after repairs: Use your scanner or disconnect the battery to reset the engine light once the issue is fixed.

- Monitor the light after reset: If it returns, the problem may be more serious and require professional diagnosis.

How to Fix My 2007 F150 Engine Light

If you’re driving a 2007 Ford F-150 and the dreaded check engine light suddenly pops up on your dashboard, your first instinct might be to panic. But before you rush to the mechanic and spend hundreds of dollars, know this: many engine light issues on this popular truck can be diagnosed and fixed at home with basic tools and a little know-how.

This comprehensive guide will walk you through every step—from reading the trouble code to fixing the most common problems and resetting the light. Whether you’re a weekend mechanic or a complete beginner, you’ll learn how to troubleshoot your F-150’s engine light like a pro. By the end, you’ll not only save money but also gain confidence in maintaining your truck.

Let’s get started.

Step 1: Understand Why the Engine Light Comes On

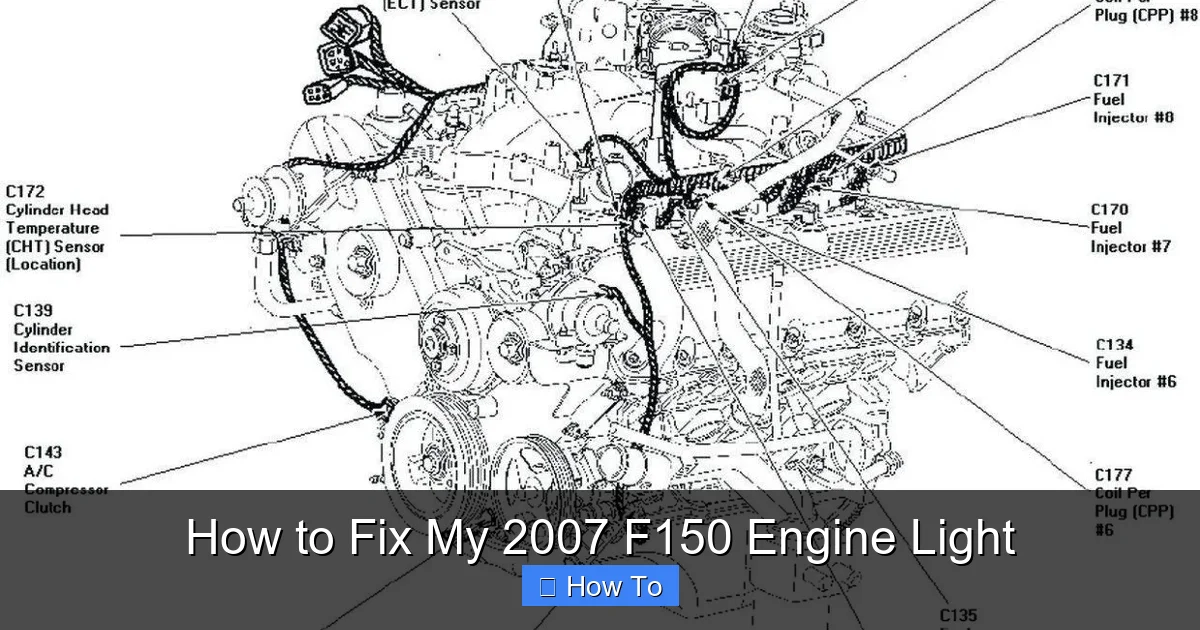

Visual guide about How to Fix My 2007 F150 Engine Light

Image source: i.pinimg.com

The check engine light—also known as the malfunction indicator lamp (MIL)—is part of your truck’s onboard diagnostic system (OBD2). When the engine control unit (ECU) detects a problem that could affect emissions or engine performance, it turns on the light to alert you.

But here’s the thing: the engine light doesn’t tell you *what* is wrong—only that *something* is wrong. It could be a minor issue like a loose gas cap or a serious problem like a failing catalytic converter. That’s why the first step is always to read the diagnostic trouble code (DTC).

Common Reasons for the Engine Light in a 2007 F-150

- Oxygen (O2) sensor failure: These sensors monitor exhaust gases and help the engine adjust the air-fuel mixture. A faulty sensor can reduce fuel economy and increase emissions.

- Loose or damaged gas cap: This triggers the EVAP system code (P0455 or P0457) and is one of the most common—and easiest—fixes.

- Spark plug or ignition coil issues: Misfires (codes like P0300-P0308) are frequent in high-mileage F-150s and can cause rough idling or poor acceleration.

- Mass airflow (MAF) sensor problems: A dirty or failing MAF sensor can cause hesitation, stalling, or poor fuel efficiency.

- Catalytic converter failure: Often a result of long-term neglect, this is a more expensive repair but usually gives warning signs first.

- Exhaust gas recirculation (EGR) valve issues: Clogged or stuck EGR valves can cause rough idle and increased emissions.

Understanding these common causes helps you focus your troubleshooting efforts and avoid unnecessary repairs.

Step 2: Get an OBD2 Scanner

To fix your engine light, you need to know what’s causing it. That’s where an OBD2 scanner comes in.

The 2007 Ford F-150 uses the OBD2 system, which means any standard OBD2 scanner will work. You don’t need a fancy or expensive model—basic scanners cost as little as $20 and are widely available online or at auto parts stores.

How to Use an OBD2 Scanner

- Locate the OBD2 port: In your 2007 F-150, it’s usually under the dashboard on the driver’s side, near the steering column. It’s a 16-pin connector that looks like a trapezoid.

- Turn the ignition to “ON” (but don’t start the engine): This powers up the ECU and allows the scanner to communicate with the truck’s computer.

- Plug in the scanner: Insert the scanner’s connector into the OBD2 port. Most scanners will power on automatically.

- Follow the on-screen prompts: Select “Read Codes” or a similar option. The scanner will retrieve the stored trouble codes.

- Write down the code(s): Codes usually start with a letter (P, B, C, or U) followed by four digits (e.g., P0420). Write them down for reference.

Pro tip: Some scanners also show live data, freeze frame data, and readiness monitors. These features can help you understand the conditions when the code was set.

Understanding the Trouble Code

Once you have the code, use the scanner’s built-in database or search online to decode it. For example:

- P0420: Catalyst system efficiency below threshold (Bank 1)

- P0304: Cylinder 4 misfire detected

- P0171: System too lean (Bank 1)

- P0455: Large EVAP leak detected

Knowing the exact code helps you target the right repair instead of guessing.

Step 3: Check the Gas Cap

Before diving into complex repairs, start with the simplest fix: the gas cap.

A loose, cracked, or missing gas cap is one of the most common reasons for the check engine light in any vehicle, including the 2007 F-150. It triggers an EVAP (evaporative emissions) system code because the system can’t maintain proper pressure.

How to Inspect and Fix the Gas Cap

- Turn off the engine and let the truck cool.

- Open the fuel door and remove the gas cap.

- Inspect the cap: Look for cracks, worn rubber seals, or damage. The seal should be soft and intact.

- Check the threads: Make sure they’re not stripped or dirty.

- Tighten the cap properly: Screw it on until you hear it click 3–5 times. This ensures a proper seal.

- Clear the code: Use your OBD2 scanner to reset the engine light. Drive the truck for a few days. If the light stays off, the problem is solved.

If the cap is damaged, replace it with an OEM or high-quality aftermarket cap. Avoid cheap universal caps—they often don’t seal properly.

Step 4: Inspect and Replace Spark Plugs and Ignition Coils

Misfire codes (like P0300, P0301, etc.) are common in 2007 F-150s, especially those with over 100,000 miles. These codes indicate that one or more cylinders aren’t firing correctly, which can be caused by worn spark plugs or faulty ignition coils.

How to Check Spark Plugs

- Locate the spark plugs: On the 5.4L V8 engine, they’re on top of the engine, under the ignition coil covers. Each cylinder has one coil and one plug.

- Remove the ignition coil: Unplug the electrical connector and use a socket wrench to remove the coil bolt. Gently pull the coil out.

- Remove the spark plug: Use a spark plug socket and extension to unscrew the plug.

- Inspect the plug: Look for signs of wear:

- Normal: Light gray or tan electrode

- Worn: Eroded electrode, wide gap

- Oil-fouled: Black, greasy deposits (possible piston ring or valve seal issue)

- Overheated: White or blistered insulator

- Check the gap: Use a gap tool to measure the distance between the center and ground electrode. The 2007 F-150 5.4L should be 0.052–0.056 inches. Adjust if needed.

If the plugs are worn or damaged, replace them. Use OEM-specified plugs (like Motorcraft or Autolite) for best performance.

How to Test Ignition Coils

Ignition coils can fail without visible signs. To test them:

- Swap the suspect coil with a known good one: For example, if you have a P0304 code (cylinder 4), swap the coil from cylinder 4 with cylinder 1.

- Clear the code and drive the truck.

- Read the codes again: If the misfire moves to cylinder 1, the coil is bad. If it stays on cylinder 4, the issue may be the plug or fuel injector.

Replacing a faulty coil is straightforward—just reverse the removal steps. Use quality replacement coils to avoid future issues.

Step 5: Clean or Replace the Mass Airflow (MAF) Sensor

The MAF sensor measures how much air enters the engine and helps the ECU calculate the correct fuel mixture. A dirty or failing MAF can cause codes like P0171 (system too lean) or P0174 (system too lean, Bank 2), leading to poor fuel economy, hesitation, or stalling.

How to Clean the MAF Sensor

- Locate the MAF sensor: It’s in the air intake duct, between the air filter box and the throttle body.

- Disconnect the electrical connector: Press the tab and pull it off.

- Remove the sensor: Use a screwdriver to remove the mounting screws.

- Spray with MAF cleaner: Use a dedicated MAF sensor cleaner (not carb cleaner or brake cleaner). Spray both the wires and the housing. Let it dry completely.

- Reinstall the sensor: Reconnect the electrical connector and secure it with screws.

- Clear the code and test drive: The engine light should go off if the MAF was the issue.

If cleaning doesn’t work, the sensor may need replacement. OEM sensors are more reliable than cheap aftermarket ones.

Step 6: Check the Oxygen (O2) Sensors

O2 sensors monitor the oxygen content in the exhaust and help the engine adjust the air-fuel ratio. A failing sensor can cause poor fuel economy, increased emissions, and codes like P0133 (O2 sensor slow response) or P0153.

The 2007 F-150 has multiple O2 sensors:

- Upstream sensors (before the catalytic converter): One for each bank (Bank 1 and Bank 2)

- Downstream sensors (after the catalytic converter): Also one per bank

How to Test and Replace O2 Sensors

- Locate the sensor: Use your trouble code to identify which sensor is faulty. For example, P0133 refers to Bank 1, Sensor 1 (upstream).

- Disconnect the electrical connector: Press the tab and pull it off.

- Remove the sensor: Use an O2 sensor socket or a wrench. Be careful—it may be tight or seized.

- Install the new sensor: Apply anti-seize compound to the threads (if recommended) and tighten to spec (usually 30 ft-lbs).

- Reconnect the electrical connector.

- Clear the code and test drive.

Replacing O2 sensors can be tricky due to access and corrosion. If you’re not comfortable, consider professional help.

Step 7: Address Catalytic Converter Issues

A failing catalytic converter often triggers codes like P0420 or P0430. While this is a more serious and expensive repair, it’s usually preceded by other symptoms:

- Reduced engine performance

- Loud exhaust noise (rattling)

- Strong sulfur (rotten egg) smell

- Increased fuel consumption

How to Diagnose a Bad Catalytic Converter

- Check for other codes: A P0420 code alone doesn’t always mean the cat is bad. It could be caused by a faulty O2 sensor or engine misfire.

- Use a backpressure test: A mechanic can measure exhaust backpressure to confirm blockage.

- Inspect for physical damage: Look for dents, rust, or rattling sounds.

- Monitor O2 sensor readings: A good catalytic converter should smooth out the downstream O2 sensor signal. If it looks like the upstream signal, the cat may be clogged.

Replacing a catalytic converter is complex and often requires welding. It’s best left to professionals, especially since emissions laws vary by state.

Step 8: Reset the Engine Light

After fixing the issue, you need to clear the trouble code to turn off the engine light.

How to Clear the Code

- Use your OBD2 scanner: Select “Clear Codes” or “Erase DTCs.” This is the easiest and most reliable method.

- Disconnect the battery (alternative method):

- Turn off the engine and remove the key.

- Disconnect the negative battery terminal.

- Wait 15–30 minutes (this resets the ECU).

- Reconnect the battery.

Note: Disconnecting the battery may also reset radio presets, clock, and other settings.

Monitor the Light

After clearing the code, drive the truck for a few days. If the engine light stays off, the problem is likely fixed. If it returns, the issue may be intermittent or more complex.

Troubleshooting Tips

- Don’t ignore the light: Even if the truck runs fine, unresolved issues can damage the catalytic converter or reduce fuel efficiency.

- Use quality parts: Cheap replacements may fail quickly. Stick with OEM or reputable brands.

- Keep records: Note the code, repair, and date. This helps if the problem returns or when selling the truck.

- Check for Technical Service Bulletins (TSBs): Ford may have issued updates for common 2007 F-150 issues. Search online or ask a dealer.

- When to see a mechanic: If you’ve tried the common fixes and the light keeps coming back, or if you’re unsure about a repair, consult a professional.

Conclusion

Fixing the engine light on your 2007 Ford F-150 doesn’t have to be stressful or expensive. By following this guide, you’ve learned how to read trouble codes, inspect common components, and perform basic repairs at home.

Start with the simple fixes—like checking the gas cap or cleaning the MAF sensor—before moving to more complex repairs. Most engine light issues on this truck are caused by sensors, spark plugs, or emissions components that are relatively easy to replace.

Remember, the key is to diagnose the problem correctly. Don’t just clear the code and hope it goes away. Fix the root cause, then reset the light and monitor your truck’s performance.

With a little patience and the right tools, you can keep your F-150 running smoothly for years to come—and save hundreds in mechanic bills along the way.