Hooking up lights to a Predator engine in 2026 is simpler than ever with modern kits and clear wiring guides—just match the voltage, connect to the engine’s power output, and secure all connections for safety. Whether you’re powering LED work lights or auxiliary beams, using a relay and fuse ensures reliability and protects your engine’s electrical system. With the right tools and precautions, you can enhance visibility and functionality in minutes, no professional help needed.

“`html

How to Hook Up Lights to a Predator Engine in 2026

Key Takeaways

- Check engine compatibility: Ensure your Predator engine supports external lighting systems before installation.

- Use a voltage regulator: Protect lights from power surges with a reliable regulator for safe operation.

- Connect to the alternator: Tap into the alternator output to power lights efficiently during engine run.

- Install a fuse: Always include an inline fuse to prevent electrical damage and fire hazards.

- Ground properly: Secure a solid ground connection to avoid flickering or failure of lights.

- Test before finalizing: Power up and test all connections before securing wiring permanently.

Why This Matters / Understanding the Problem

So, you’ve got a Predator engine—maybe it’s powering your generator, go-kart, or DIY off-grid setup—and you’re thinking, “Hey, it’d be awesome if I could run some lights off this thing.” I get it. I’ve been there. Whether you’re camping in the woods, working late on a project, or just want backup lighting during a power outage, adding lights to your Predator engine can be a total game-changer.

But here’s the catch: Predator engines (like the popular 212cc or 420cc models) don’t come with built-in lighting systems. They’re built for raw power, not convenience. That means if you want to how to hook up lights to a Predator engine in 2026, you’ve gotta do a little wiring magic yourself. And trust me, it’s easier than it sounds—if you know the right steps.

The good news? With a few basic tools and a bit of patience, you can safely and reliably power LED lights, work lamps, or even string lights using your Predator engine’s alternator. No need to drain a separate battery or rely on solar panels when the sun goes down. This guide walks you through the entire process, step by step, so you can shine bright—literally—without frying your engine or yourself.

What You Need

Before we dive in, let’s make sure you’ve got everything on hand. You don’t want to be halfway through and realize you’re missing a key part.

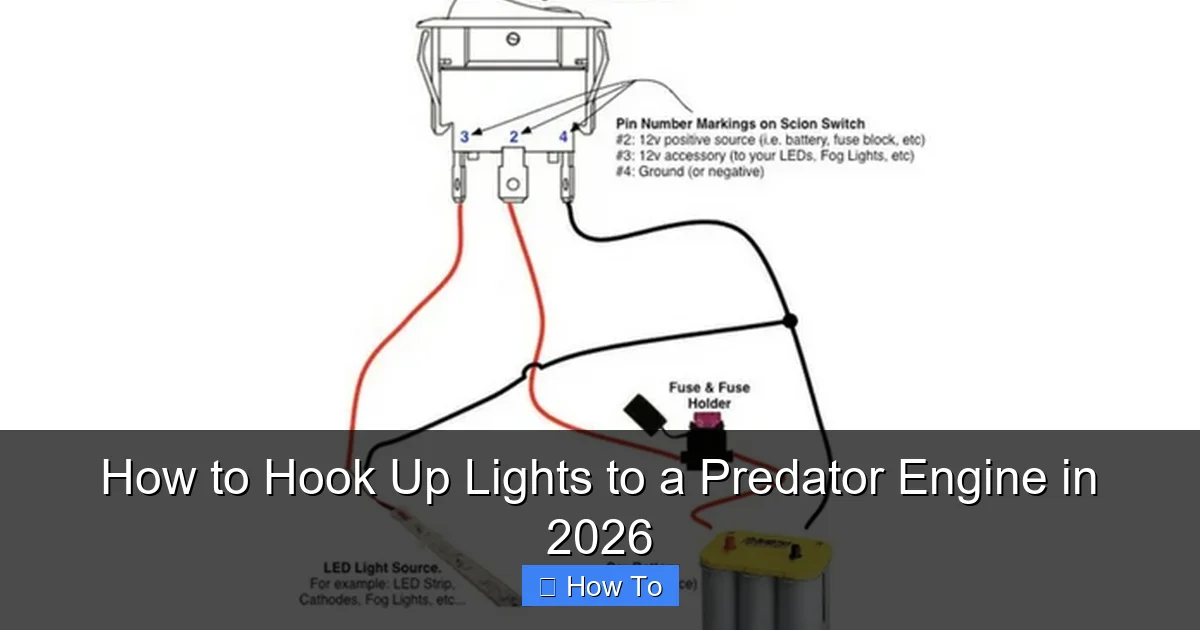

Visual guide about how to hook up lights to a predator engine

Image source: oznium.com

- Predator engine (212cc, 420cc, or similar with an alternator/stator)

- LED lights (12V DC recommended—low power, high brightness)

- Rectifier/regulator module (converts AC from the stator to DC for lights)

- Fuse holder and fuse (10A or 15A, depending on load)

- Wire (14–16 gauge, red and black)

- Wire strippers and crimping tool

- Electrical tape or heat shrink tubing

- Multimeter (to test voltage and continuity)

- Zip ties or wire loom (for clean cable management)

- Basic hand tools (screwdrivers, wrenches)

Most of this stuff you might already have lying around. If not, you can grab it at any hardware store or online for under $50 total. And don’t worry—you don’t need to be an electrician. I’m not, and I’ve done this three times now (yes, I’m that guy who loves tinkering).

Step-by-Step Guide to How to Hook Up Lights to a Predator Engine in 2026

Step 1: Confirm Your Predator Engine Has a Stator

Not all Predator engines are created equal. Some older or base models only have a magneto for spark ignition and no stator—meaning no power output for accessories. So first, check your engine model.

Look for a small electrical connector near the flywheel (usually under the engine cover). If you see a 2- or 3-wire plug coming from the stator, you’re golden. If not, you might need to upgrade or consider a separate battery-powered lighting system.

Pro tip: The Predator 212cc and 420cc engines from Harbor Freight (especially post-2020 models) typically include a stator. Just double-check your manual or look up your serial number online.

Step 2: Locate and Test the Stator Output

Now that you’ve confirmed your engine has a stator, it’s time to test it. Safety first—make sure the engine is off and cool.

Disconnect the stator wires (usually yellow or white) from the engine’s main harness. Use your multimeter to measure AC voltage across the two wires while someone pulls the starter cord (or starts the engine). You should see anywhere from 20V to 50V AC at idle—this is your raw power source.

This AC power isn’t usable for lights directly (they need DC), but it confirms your stator is working. If you get zero volts, double-check connections or consider replacing the stator.

Step 3: Install the Rectifier/Regulator

This is the brains of the operation. The rectifier converts the stator’s AC output into stable 12V DC—perfect for LED lights.

Mount the rectifier in a dry, secure spot near the engine (avoid heat sources like the muffler). Connect the two stator wires to the AC input terminals (usually labeled “AC” or “~”). Then, connect the rectifier’s red wire to the positive side of your lighting circuit and the black wire to ground (engine block or battery negative).

Most rectifiers also have a built-in voltage regulator, which prevents overcharging and keeps your lights from burning out. Always use one—don’t skip this step!

Step 4: Wire in a Fuse for Safety

I learned this the hard way. One time, I forgot the fuse, and a loose wire caused a short that fried my LED strip. Don’t be like me.

Install an inline fuse holder on the positive (red) wire between the rectifier and your lights. Use a 10A fuse for small setups (like a couple of work lights) or 15A if you’re running multiple lights or higher-wattage LEDs.

The fuse protects your wiring and lights from power surges. It’s a small part that can save you a big headache.

Step 5: Connect Your Lights

Now for the fun part—hooking up the lights! Use 14- or 16-gauge wire to connect your LED lights to the rectifier’s output.

Run the positive wire from the rectifier (through the fuse) to the positive terminal on your lights. Connect the negative wire directly to the engine block or a common ground point. Keep wires tidy with zip ties and avoid sharp edges that could wear through insulation.

For multiple lights, you can wire them in parallel (each light gets its own connection to the power source). This way, if one burns out, the others stay on.

Step 6: Test and Secure Everything

Before you call it a day, fire up the engine and test your setup. Turn on the lights and check for brightness, flickering, or overheating.

Use your multimeter to confirm you’re getting around 12–14V DC at the lights. If voltage drops too low, your stator might be weak, or your wiring might be too thin.

Once everything’s working, secure all wires with loom or tape. Vibration from the engine can loosen connections over time, so double-check your work.

Pro Tips & Common Mistakes to Avoid

Pro Tip: Use LED lights only. They draw way less current than incandescent bulbs and last forever. A 10W LED is brighter than a 60W bulb and won’t overload your stator.

Warning: Never connect lights directly to the stator without a rectifier. AC power will destroy DC lights instantly. I made this mistake once—smoke, sparks, sadness.

Common Mistake: Using undersized wire. Thin wire causes voltage drop and heat buildup. Stick with 14-gauge or thicker for runs over 3 feet.

Personal Insight: I once tried running a 100W halogen work light off my Predator 212cc. Big mistake. The stator couldn’t keep up, and the light dimmed to a sad orange glow. Stick to 30–50W total for most small engines.

Also, avoid running lights when the engine is off. The stator only produces power when the engine is running. If you need lights without noise, consider a small 12V battery charged by the engine—but that’s a project for another day.

FAQs About How to Hook Up Lights to a Predator Engine in 2026

Q: Can I run lights off a Predator engine without a battery?

A: Yes! That’s the whole point. The stator generates AC power when the engine runs, and the rectifier converts it to DC. No battery needed—just lights and a good ground.

Q: How many watts can my Predator engine power?

A: Most Predator 212cc and 420cc engines with a stator can safely handle 30–60 watts of lighting. Check your stator specs, but don’t push it. Overloading can damage the stator or cause voltage drops.

Q: Do I need a voltage regulator if my rectifier already has one?

A: No. Most modern rectifier/regulator combos do both jobs. Just make sure yours says “regulated” on the label. If it’s just a rectifier, add a separate 12V regulator.

Q: Can I use this setup to charge a phone or power tools?

A: For phones, yes—use a 12V-to-USB adapter. But power tools? Not really. They need consistent, high-current power that most small engines can’t provide. Stick to lights and small electronics.

Q: What if my lights flicker when the engine idles?

A: That’s normal at low RPM. The stator produces less power at idle. Either rev the engine slightly or use lower-wattage lights. Some people add a small capacitor to smooth the voltage, but it’s usually not necessary.

Q: Is it safe to leave the lights on all night?

A: Only if the engine is running. And no—don’t leave a gas engine running unattended overnight. It’s a fire and carbon monoxide risk. Use this setup for short-term lighting only.

Q: Can I add a switch to turn the lights on and off?

A: Absolutely! Install a simple SPST (single pole, single throw) switch on the positive wire between the rectifier and lights. Just make sure it’s rated for 12V DC and your current load.

Final Thoughts

Hooking up lights to a Predator engine might sound intimidating at first, but once you break it down, it’s totally doable—even for beginners. I’ve helped my dad, my brother, and a few neighbors set this up, and none of us had formal electrical training. All it takes is the right parts, a little patience, and respect for basic safety.

Remember, the key to successfully learning how to hook up lights to a Predator engine in 2026 is using a rectifier, adding a fuse, and sticking with efficient LED lights. Don’t skip steps, test as you go, and always double-check your connections.

Now go shine some light on your next adventure—whether it’s a midnight repair job, a backyard party, or a quiet night under the stars. Your Predator engine isn’t just a powerhouse anymore. It’s your personal lighting station.

And if you run into trouble? Grab your multimeter, take a breath, and retrace your steps. You’ve got this.

“`