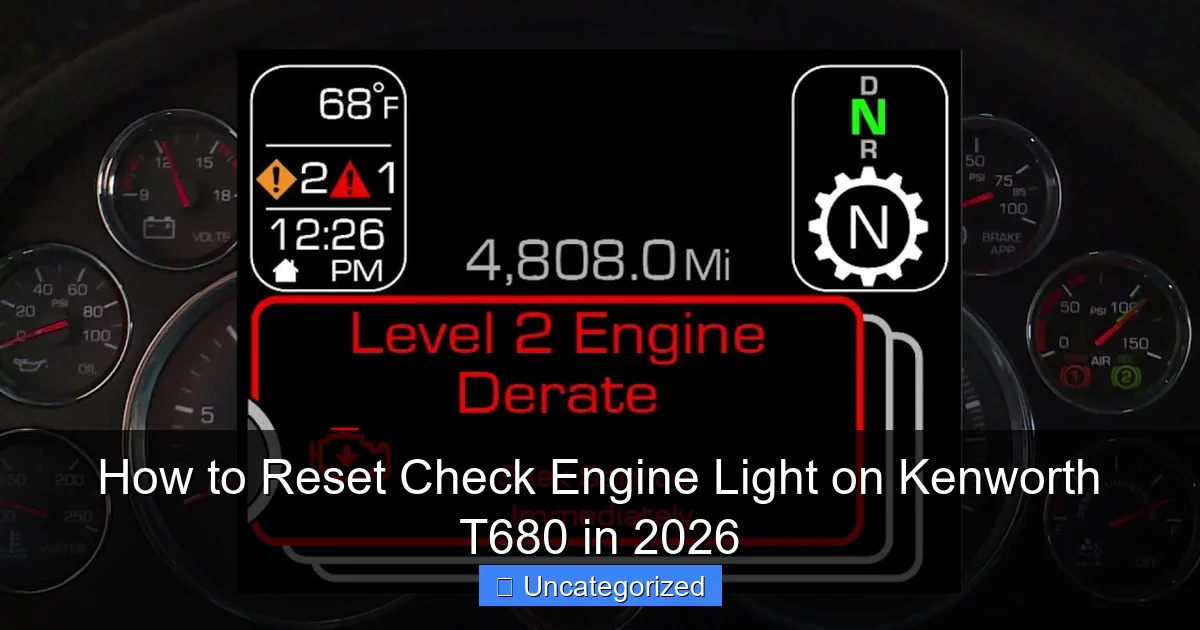

Featured image for how to reset check engine light on kenworth t680

Image source: i1.wp.com

Resetting the check engine light on a 2026 Kenworth T680 is a straightforward process when you use an OBD-II scanner or follow the truck’s built-in reset procedure after addressing the underlying issue. Always diagnose and repair the root cause first—simply clearing the code without fixing it risks engine damage and failed emissions. For a safe, lasting reset, ensure all fault codes are resolved and the vehicle passes a post-repair diagnostic scan.

How to Reset Check Engine Light on Kenworth T680 in 2026

Key Takeaways

- Diagnose first: Always scan for codes before resetting to address underlying issues.

- Use an OBD2 scanner: Required for safe, effective reset on 2026 T680 models.

- Turn ignition on: Power up without starting engine to begin the reset process.

- Clear codes properly: Follow scanner prompts to erase all stored error codes.

- Verify reset success: Confirm light stays off after driving a short test cycle.

- Check fluid levels: Low DEF or oil can trigger lights—top off if needed.

- Consult dealer: For persistent lights, professional service may be necessary.

Why This Matters / Understanding the Problem

The check engine light on your Kenworth T680 is more than just an annoying orange glow on your dashboard. It’s your truck’s way of saying, “Hey, something’s off.” Whether it’s a loose gas cap or a serious engine misfire, ignoring it could lead to expensive repairs or even a roadside breakdown.

Knowing how to reset check engine light on Kenworth T680 in 2026 gives you control. But here’s the catch: resetting it without fixing the root cause is like silencing a smoke alarm with a pillow. You need to diagnose first, then reset—safely and correctly.

In 2026, Kenworth T680 models come with advanced diagnostic systems, including J1939 CAN bus communication and integrated telematics. That means the check engine light isn’t just a simple on/off switch. It’s tied to real-time engine data, emissions compliance, and even fleet management software.

So why does this matter? Because a reset isn’t a fix. It’s a step in a process. If you’re a fleet driver, owner-operator, or maintenance tech, understanding this process helps you stay compliant, avoid downtime, and keep your rig running smoothly.

Whether you’re preparing for a DOT inspection, trying to pass emissions, or just want peace of mind, learning how to reset check engine light on Kenworth T680 in 2026 is a must-have skill.

What You Need

Before you dive into the reset process, make sure you have the right tools. The good news? You don’t need a full garage. But you do need a few key items to do it safely and effectively.

Visual guide about how to reset check engine light on kenworth t680

Image source: i2.wp.com

- OBD2 Scanner (J1939 Compatible): Not all OBD2 tools work with heavy-duty trucks. You need one that supports J1939 protocol, like the Autel MaxiCOM MK908, Bosch 2.0, or Snap-on Zeus. Generic car scanners won’t cut it.

- Kenworth Diagnostic Software (Optional but Helpful): Tools like Kenworth PACCAR MX or Witech give deeper access to engine modules, DTCs (diagnostic trouble codes), and freeze frame data.

- Smartphone or Tablet (for Telematics Apps): Many 2026 T680s use PACCAR Connect or Geotab for real-time diagnostics. These apps can show pending codes and help verify fixes.

- Flashlight and Gloves: For inspecting under the hood or dashboard connections.

- Notebook or Phone Notes: Write down any DTCs before resetting. You’ll thank yourself later.

- Access to a Charger or Power Source: Make sure your battery is stable. A weak battery can cause false codes or reset failures.

Pro Tip: If you’re part of a fleet, check with your maintenance manager. Some companies have proprietary tools or require technician approval before resetting any warning lights. Safety and compliance come first.

Having these tools ensures you’re not just resetting the light—you’re diagnosing the issue and confirming it’s truly resolved. That’s how you avoid repeat problems and keep your Kenworth T680 running like new.

Step-by-Step Guide to How to Reset Check Engine Light on Kenworth T680 in 2026

Now that you’re equipped, let’s walk through the actual process. This guide covers both the manual reset method (for minor, resolved issues) and the diagnostic reset method (for serious or recurring codes). We’ll also explain when to use each.

Remember: How to reset check engine light on Kenworth T680 in 2026 isn’t just about pushing buttons. It’s about understanding what the light means and acting responsibly.

Step 1: Park Safely and Power Down the System

First things first—safety. Pull over in a safe, flat area. Turn off the engine and set the parking brake. Wait at least 30 seconds before disconnecting any systems. This gives the ECM (Engine Control Module) time to shut down cleanly.

Never reset the check engine light while the engine is running or the truck is in motion. That can corrupt data or trigger false codes.

Warning: If the light is flashing (not steady), stop immediately. A flashing check engine light means a severe misfire that can damage the catalytic converter. Do not drive far—call a mechanic.

Once parked, turn the ignition to the “ON” position (but don’t start the engine). This powers the dashboard and OBD2 port without engaging the fuel system.

Step 2: Plug in the J1939-Compatible OBD2 Scanner

Locate the OBD2 port. On the 2026 Kenworth T680, it’s usually under the dashboard on the driver’s side, near the steering column. It’s a 9-pin or 16-pin connector (J1939 uses 9-pin for heavy-duty).

Plug in your scanner. Make sure it powers on. If it doesn’t, check the fuse (usually labeled “OBD2” or “Data Link” in the fuse box). A dead fuse is a common issue after long hauls.

Turn on the scanner and select “Heavy-Duty Trucks” or “J1939” mode. Wait for it to connect to the ECM. This usually takes 10–30 seconds.

Pro Tip: Some scanners need a “handshake” with the truck’s CAN bus. If it fails, try turning the ignition off and on again. Or, unplug and reseat the connector firmly.

Once connected, the scanner will show a list of modules: ECM, TCM (Transmission Control Module), ABS, etc. Select the ECM—that’s where the check engine light lives.

Step 3: Read and Record All Diagnostic Trouble Codes (DTCs)

Now, hit “Read DTCs” or “Scan for Codes.” The scanner will pull all active and pending codes. For example:

- P0401 – Exhaust Gas Recirculation (EGR) Flow Insufficient

- P2263 – Turbo Boost Pressure Not Detected

- P0171 – System Too Lean (Bank 1)

Write down every code. Don’t skip this step. Even if the light is off, a pending code can reappear after a few drive cycles.

Use the scanner’s “Freeze Frame” feature. It shows engine conditions (RPM, coolant temp, load) at the moment the code was set. This helps diagnose intermittent issues.

Ask yourself: Has this code appeared before? If yes, it might be a recurring problem like a faulty sensor or clogged filter.

Pro Tip: Search the code online or in the scanner’s built-in database. For example, “P0401 Kenworth T680” might show common fixes like a dirty EGR valve or faulty differential pressure sensor.

Step 4: Fix the Underlying Problem (Don’t Skip This!)

This is the most important step. Never reset the check engine light without fixing the cause. Here are common issues and fixes for the 2026 T680:

- Loose or Damaged Fuel Cap: Tighten or replace it. A bad seal causes pressure loss and triggers P0457.

- Dirty or Faulty EGR Valve: Clean with EGR-safe cleaner or replace. Common on trucks with high idle hours.

- Faulty O2 Sensors: Replace upstream or downstream sensors. Use OEM or high-quality aftermarket (like NTK or Bosch).

- Clogged DPF (Diesel Particulate Filter): Run a forced regeneration (via scanner) or replace if damaged.

- Turbo Boost Leak: Check for cracked hoses or loose clamps in the charge air cooler system.

- Low DEF (Diesel Exhaust Fluid): Top off the tank. Low DEF triggers P20EE and disables the engine.

After fixing the issue, run the engine for 10–15 minutes to stabilize. This lets the ECM recalibrate and confirm the problem is gone.

Warning: If you don’t know what a code means or how to fix it, don’t guess. Call a certified Kenworth technician. Misdiagnosing can lead to engine damage or void your warranty.

Step 5: Clear the DTCs and Reset the Check Engine Light

Now it’s time to reset. Go back to your scanner and select “Clear DTCs” or “Erase Codes.” Confirm the action.

The scanner will send a signal to the ECM to erase all active and pending codes. You’ll see a message like “Codes Cleared Successfully.”

Turn off the scanner and unplug it. Wait 10 seconds, then turn the ignition to “OFF.”

Now, turn the ignition back to “ON” (no engine start). The check engine light should be off. If it stays on, repeat the scan—there might be a new code or the fix didn’t work.

Pro Tip: Some codes require multiple drive cycles to fully clear. For example, the DPF regeneration code may not reset until you drive 50+ miles with steady RPMs. Be patient.

Step 6: Perform a Test Drive and Monitor the System

Start the engine. Let it idle for 2–3 minutes. The light should stay off. If it flickers, shut down immediately and re-scan.

Now, take the truck for a 15–20 minute test drive. Include:

- Highway speeds (60–70 mph)

- Hill climbs (to test turbo and transmission)

- Sudden stops (to test ABS and emissions)

During the drive, watch the dashboard. If the light comes back, stop and scan again. Note the new code.

After the drive, plug the scanner back in. Use “Read DTCs” to confirm no new codes. If all is clear, the reset was successful.

Pro Tip: Use your truck’s telematics app (like PACCAR Connect) to monitor real-time engine data. Look for abnormal values in boost pressure, exhaust temp, or NOx levels.

Step 7: Verify with a Second Scan (Optional but Recommended)

For extra confidence, run a second scan 24–48 hours later. This checks for delayed or intermittent codes that might not show up immediately.

Some sensors (like the NOx sensor) take time to self-test. A follow-up scan ensures the system is truly clean.

If the light stays off and no codes return, you’ve successfully completed the process. Congratulations!

Pro Tips & Common Mistakes to Avoid

Even experienced drivers make mistakes when resetting the check engine light. Here’s how to avoid the most common pitfalls—and do it right every time.

Pro Tip #1: Always Diagnose First, Reset Second

Too many drivers plug in a scanner, clear the code, and hit the road. That’s dangerous. A reset without diagnosis is like putting a bandage on a broken leg.

Example: You get a P0401 (EGR flow). You reset it. The light comes back after 100 miles. Now you’ve wasted time and risked engine damage. Fix the EGR valve first—then reset.

Pro Tip #2: Use the Right Tool for the Job

Generic OBD2 scanners (like the $20 ones from Amazon) often can’t read heavy-duty codes. They might show “No Communication” or give false readings.

Invest in a J1939-compatible scanner. Yes, it costs more—but it’s worth it. Think of it as insurance against costly mistakes.

Pro Tip #3: Check for Pending Codes

Some codes are “pending”—they haven’t triggered the light yet but are close. Your scanner will show them under “Pending DTCs.”

If you clear only active codes but ignore pending ones, the light will come back fast. Always clear both.

Pro Tip #4: Reset During a Stable Engine State

Don’t reset the light right after a cold start or hard drive. The engine needs to stabilize. Wait until it’s at normal operating temperature (around 195°F).

Otherwise, you might clear a code that will reappear once the system self-tests.

Common Mistake #1: Ignoring the Flashing Light

A steady light? Usually safe to drive to a shop. A flashing light? Stop immediately. It means a severe misfire that can melt your catalytic converter.

Resetting a flashing light without fixing the issue is reckless. It can cost you $5,000+ in repairs.

Common Mistake #2: Using the “Battery Disconnect” Trick

Some drivers disconnect the battery to reset the light. This might work for old trucks, but not the 2026 T680.

Modern ECMs store codes in non-volatile memory. Disconnecting the battery won’t erase them. Plus, it can reset your radio, GPS, and engine adaptations.

Common Mistake #3: Forgetting to Record Codes

You clear the code, but don’t write it down. A week later, the light comes back. You’ve lost valuable diagnostic history.

Keep a logbook or use a notes app. Track every code, fix, and reset. It helps spot patterns and saves time on future repairs.

FAQs About How to Reset Check Engine Light on Kenworth T680 in 2026

Got questions? We’ve got answers. Here are the most common ones we hear from drivers and techs.

Q1: Can I reset the check engine light without a scanner?

Technically, yes—but it’s not recommended. Some older methods (like turning the key on/off 3 times) don’t work on 2026 T680s. The safest way is with a J1939 scanner. Without one, you can’t read the code or confirm the fix. It’s like driving blindfolded.

Q2: Will resetting the light clear my DPF regeneration history?

No. Resetting the check engine light only clears DTCs. It doesn’t reset DPF regeneration logs, which are stored separately. For a full DPF reset, you need a forced regeneration via scanner or dealership software.

Q3: How long does it take for the light to come back after a reset?

It depends on the issue. A simple loose cap? Light stays off. A faulty sensor? Might come back in 50–200 miles. A severe issue? It could return in minutes. Always monitor your truck for at least 24 hours post-reset.

Q4: Can I pass emissions with a reset check engine light?

Maybe. Most states require the light to be off and all monitors to be “ready.” A reset might turn off the light, but monitors (like O2 sensor or catalyst) may need 50–100 miles to complete self-tests. Check your state’s rules.

Q5: What if the light comes back after a successful reset?

Don’t panic. It means the fix didn’t work or the issue is intermittent. Re-scan, record the new code, and investigate further. Common culprits: wiring harnesses, corroded connectors, or failing sensors.

Q6: Can I use my phone to reset the check engine light?

Only if you have a Bluetooth OBD2 adapter and a compatible app (like Torque Pro or Heavy Duty Scan). But again, it must support J1939. Most phone apps are for light-duty vehicles. For T680, a dedicated scanner is better.

Q7: Is it illegal to reset the check engine light?

No—as long as you’ve fixed the problem. It’s illegal to reset it to hide a defect (like a missing catalytic converter). But diagnosing and resetting after a repair is perfectly legal and encouraged.

Final Thoughts

Learning how to reset check engine light on Kenworth T680 in 2026 isn’t just about silencing a warning. It’s about understanding your truck, staying safe, and avoiding costly repairs.

Remember: Reset is the last step, not the first. Diagnose, fix, verify, then reset. Use the right tools, record your codes, and never ignore a flashing light.

For fleet drivers, this knowledge keeps you on the road and out of the shop. For owner-operators, it saves time and money. For techs, it builds trust with your clients.

Next time that orange light pops on, don’t panic. Grab your scanner, follow these steps, and take control. Your Kenworth T680 will thank you—and so will your wallet.

Now go reset that light the right way. Safe travels!