Discover the correct method to jump your 1994 Oldsmobile 98 to reset the check engine light without damaging your vehicle’s computer. This guide walks you through safe procedures, common mistakes to avoid, and when to seek professional help.

If you’re driving a classic 1994 Oldsmobile 98 and that dreaded check engine light pops on, don’t panic—yet. While modern cars rely on OBD-II scanners for diagnostics, your ’94 Olds 98 uses an older OBD-I system that allows you to read trouble codes manually by “jumping” specific terminals. This process, often called “jumping the ALDL” (Assembly Line Diagnostic Link), lets you communicate directly with the car’s Engine Control Module (ECM) and retrieve diagnostic trouble codes (DTCs) using just the check engine light.

The beauty of this system is its simplicity. You don’t need expensive tools or a trip to the dealership. With a paperclip and a few minutes, you can uncover what’s triggering that warning light. Whether it’s a faulty oxygen sensor, a loose gas cap, or something more serious, jumping the ALDL gives you valuable insight into your car’s health. However, it’s important to do this correctly—mistakes can lead to misdiagnosis or even damage your vehicle’s electronics.

In this guide, we’ll walk you step-by-step through how to jump your 1994 Olds 98 to read the check engine light codes. We’ll cover everything from locating the right connector to interpreting the flashes, plus tips to keep your classic ride running smoothly. Whether you’re a seasoned DIYer or a first-time tinkerer, this method is accessible, affordable, and empowering.

Key Takeaways

- Understand the purpose of jumping: Jumping the diagnostic terminals helps reset the ECM and clear stored trouble codes after repairs.

- Locate the correct terminals: The ALDL connector under the dashboard has specific pins (A and B) used for jumping.

- Use proper tools: A simple paperclip or jumper wire is sufficient—avoid using metal tools that could cause shorts.

- Follow safety precautions: Turn off the engine, remove the key, and wear safety glasses to prevent injury.

- Read flash codes manually: After jumping, the check engine light will flash to display trouble codes—count the flashes to diagnose issues.

- Know when to call a mechanic: If the light returns or you’re unsure about the codes, professional diagnosis is recommended.

- Maintain your vehicle regularly: Prevent future check engine lights with routine maintenance like oil changes and sensor checks.

📑 Table of Contents

Understanding the 1994 Olds 98 Check Engine Light System

Before diving into the jumping process, it’s helpful to understand how your 1994 Oldsmobile 98’s diagnostic system works. Unlike today’s vehicles that use standardized OBD-II ports and scanners, the ’94 Olds 98 relies on an older OBD-I system. This means the diagnostic interface is manufacturer-specific and requires a manual method to retrieve trouble codes.

The heart of this system is the Engine Control Module (ECM), which monitors various sensors and systems in your car. When something goes out of range—like a misfiring cylinder or a failed emissions component—the ECM stores a trouble code and triggers the check engine light. These codes are stored in the ECM’s memory until they’re cleared, either by fixing the issue or by resetting the system.

The ALDL connector is your gateway to this information. Located under the dashboard on the driver’s side, this 12-pin connector allows you to “talk” to the ECM by creating a short circuit between two specific terminals. When you jump these terminals, the ECM responds by flashing the check engine light in a pattern that corresponds to the stored trouble codes.

It’s important to note that not all check engine lights require immediate panic. Some codes indicate minor issues—like a loose gas cap or a temporary sensor glitch—while others point to serious problems like ignition failure or catalytic converter damage. By jumping the ALDL, you can identify the root cause and decide whether to fix it yourself or seek professional help.

Why Jump the ALDL?

Jumping the ALDL serves two main purposes: retrieving trouble codes and clearing them after repairs. When the check engine light comes on, jumping allows you to read the codes without a scanner. Once you’ve addressed the issue—say, replacing a faulty oxygen sensor—you can jump the terminals again to reset the ECM and turn off the light.

This method is especially useful for classic car owners who may not have access to modern diagnostic tools. It’s also a great way to verify that a repair was successful. If the light stays off after resetting, you know the problem is likely fixed. If it returns, you may need to dig deeper.

Common Misconceptions

One common myth is that jumping the ALDL will “fix” the problem. It won’t. Jumping only allows you to read or clear codes—it doesn’t repair mechanical or electrical issues. Another misconception is that you need special tools. In reality, a simple paperclip or jumper wire is all you need.

Also, don’t confuse this process with jump-starting a dead battery. Jumping the ALDL is a diagnostic procedure, not a way to start your car. Always ensure your battery has enough charge before attempting to read codes.

Locating the ALDL Connector in Your 1994 Olds 98

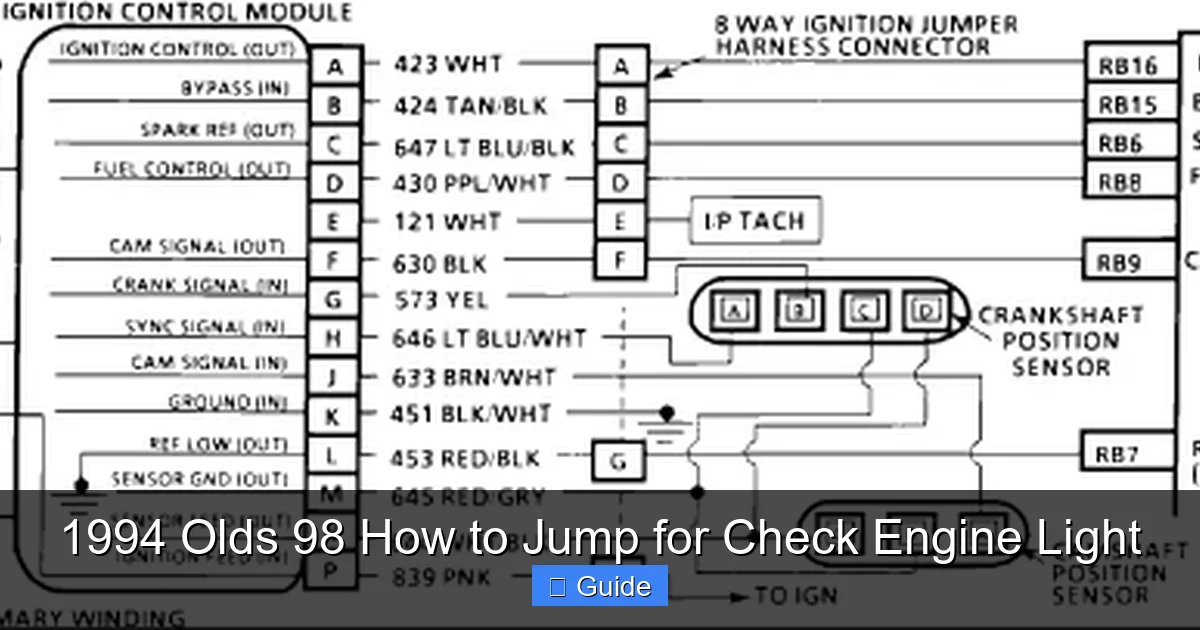

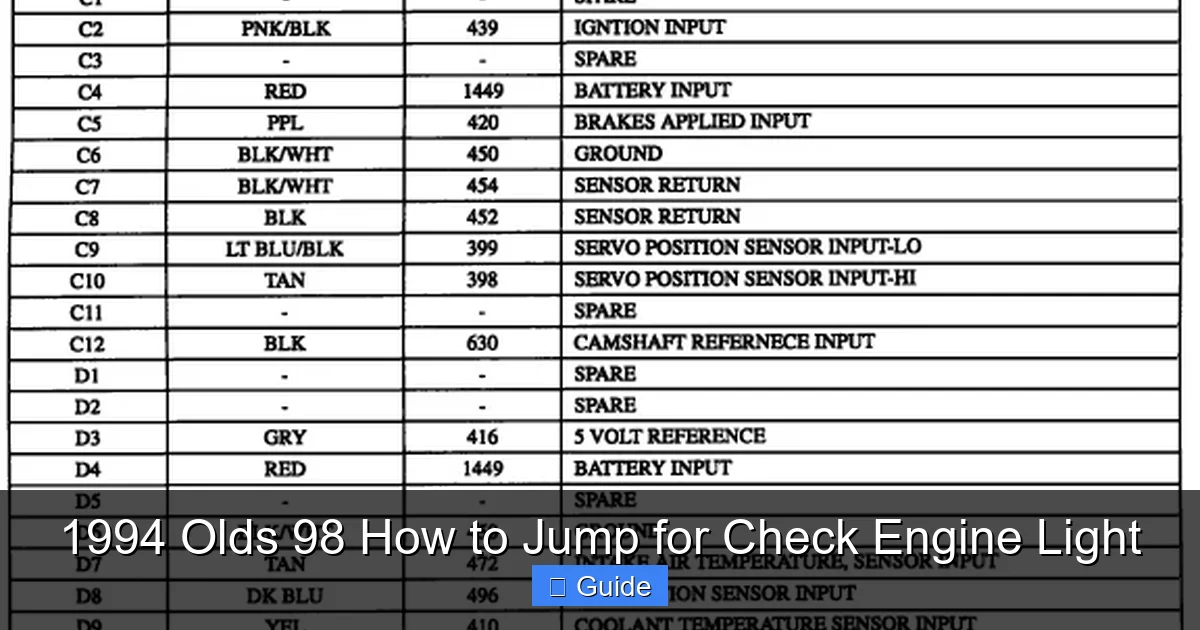

Visual guide about 1994 Olds 98 How to Jump for Check Engine Light

Image source: justanswer.com

The first step in jumping your 1994 Olds 98 is finding the ALDL connector. This 12-pin diagnostic port is typically located under the dashboard on the driver’s side, near the steering column. It’s often tucked behind a plastic panel or covered by a small door.

To locate it, sit in the driver’s seat and look down near the left side of the footwell. You should see a rectangular plastic connector with 12 pins arranged in two rows of six. It may be labeled “ALDL” or “Diagnostic,” but even if it’s not, the shape and location are consistent across most GM vehicles of this era.

If you can’t find it, check your owner’s manual or look for a small access panel that can be removed with a screwdriver. Some models have the connector mounted vertically, while others are horizontal—either way, it should be easily accessible without removing major components.

Identifying the Correct Terminals

Not all 12 pins are used for diagnostics. For jumping the ALDL, you only need to connect two specific terminals: Pin A (Ground) and Pin B (Diagnostic Enable). These are usually located at the far left of the connector.

To identify them:

– Pin A is typically the top-left pin.

– Pin B is directly below it (bottom-left).

You can confirm this by looking for small labels near the connector or referring to a wiring diagram. If in doubt, consult a repair manual for your specific model.

Tools You’ll Need

The beauty of this process is its simplicity. You don’t need expensive equipment—just a few basic items:

– A paperclip (straightened out)

– Or a short piece of insulated wire with stripped ends

– Safety glasses (optional but recommended)

– A notepad and pen to record flash codes

Avoid using metal tools like screwdrivers, as they can cause accidental shorts or damage the pins. A paperclip is ideal because it’s thin, conductive, and unlikely to cause harm if used carefully.

Step-by-Step Guide to Jumping the ALDL

Now that you’ve located the ALDL connector and identified the correct terminals, it’s time to jump the system and read the check engine light codes. Follow these steps carefully to ensure accurate results and avoid damage.

Step 1: Prepare Your Vehicle

Before you begin, make sure your car is in a safe, parked position. Turn off the engine, remove the key from the ignition, and engage the parking brake. This prevents accidental starts and ensures your safety.

Next, open the driver’s side door and locate the ALDL connector under the dashboard. Clear away any clutter or debris that might obstruct access. If the connector is behind a panel, remove it gently using a screwdriver.

Step 2: Insert the Jumper

Take your straightened paperclip or jumper wire and insert one end into Pin A (top-left) and the other end into Pin B (bottom-left). Make sure the metal parts are fully seated in the pins—loose connections can cause inaccurate readings.

You don’t need to apply force. The pins are designed to accept small wires, so a gentle push should be enough. If the paperclip feels too loose, try bending it slightly to create a tighter fit.

Step 3: Turn the Ignition On

With the jumper in place, turn the ignition key to the “ON” position—but do not start the engine. You should see the dashboard lights illuminate, including the check engine light.

At this point, the ECM will detect the jumper and begin communicating through the check engine light. The light will start flashing in a specific pattern that corresponds to the stored trouble codes.

Step 4: Read the Flash Codes

The check engine light will flash in a series of short and long pulses. Each code is represented by two numbers. For example:

– One long flash, followed by three short flashes = Code 13

– Two long flashes, followed by four short flashes = Code 24

Count the flashes carefully. Long flashes represent the tens digit, and short flashes represent the ones digit. There will be a brief pause between codes, and the sequence may repeat.

Write down each code as it appears. Some codes may appear multiple times—this is normal. Once all codes have been displayed, the light will turn off or continue flashing the same sequence.

Step 5: Remove the Jumper and Interpret the Codes

After recording all the codes, remove the jumper from the ALDL connector. Turn the ignition off and then back on to see if the check engine light remains off. If it does, the codes have been cleared.

Now, refer to a 1994 Olds 98 trouble code chart to interpret what each code means. Common codes include:

– Code 12: No distributor reference signal (often a sign the system is working normally at startup)

– Code 13: Oxygen sensor circuit malfunction

– Code 24: Vehicle Speed Sensor (VSS) issue

– Code 44: Lean exhaust indication

Use these codes to guide your next steps. For example, Code 13 might indicate a faulty O2 sensor, while Code 24 could point to a damaged speed sensor or wiring issue.

Interpreting Common Trouble Codes

Once you’ve retrieved the trouble codes, the next step is understanding what they mean. While some codes are straightforward, others require a bit of investigation. Here’s a breakdown of the most common codes you might encounter in a 1994 Olds 98.

Code 12: No Distributor Reference Signal

This code often appears during the initial diagnostic cycle and is usually not a cause for concern. It indicates that the ECM hasn’t received a signal from the distributor yet. If this is the only code and the engine runs fine, it’s likely normal.

However, if Code 12 appears repeatedly or the engine won’t start, it could signal a problem with the ignition module, distributor, or crankshaft position sensor. Check for loose connections or damaged wiring.

Code 13: Oxygen Sensor Circuit Malfunction

The oxygen sensor monitors the amount of unburned oxygen in the exhaust. Code 13 suggests the sensor isn’t sending the correct signal to the ECM. This can lead to poor fuel economy, rough idling, or increased emissions.

Common causes include a faulty O2 sensor, damaged wiring, or a vacuum leak. Replacing the sensor is often the fix, but first check the wiring harness for corrosion or breaks.

Code 24: Vehicle Speed Sensor (VSS) Issue

The VSS tells the ECM how fast the car is moving. Code 24 means the signal is missing or erratic. This can affect transmission shifting, speedometer accuracy, and cruise control.

Inspect the VSS located on the transmission. It may be dirty, loose, or damaged. Also check the wiring and connectors for wear.

Code 44: Lean Exhaust Indication

This code means the exhaust is too lean—too much air and not enough fuel. Causes include vacuum leaks, a clogged fuel filter, or a failing fuel pump.

Start by inspecting vacuum hoses for cracks or disconnections. Use a smoke test if available. If hoses are fine, check fuel pressure and consider replacing the fuel filter.

Code 54: Low Fuel Pressure

Code 54 indicates the fuel pressure is below the required level. This can cause hesitation, stalling, or difficulty starting.

Check the fuel pump, fuel filter, and fuel pressure regulator. A weak pump or clogged filter is often the culprit.

Clearing the Check Engine Light and Preventing Future Issues

After diagnosing and fixing the problem, you’ll want to clear the check engine light and ensure it doesn’t return. Here’s how to do it and keep your 1994 Olds 98 running smoothly.

Clearing the Light

Once the issue is resolved, jump the ALDL again using the same method. Turn the ignition on (engine off) with the jumper in place. The ECM will recognize the repair and clear the stored codes. The check engine light should turn off and stay off.

If the light returns, the problem may not be fully fixed, or a new issue has arisen. Recheck your work and consider a professional diagnosis.

Preventive Maintenance Tips

To avoid future check engine lights, follow these maintenance practices:

– Replace the oxygen sensor every 60,000–100,000 miles

– Check and tighten the gas cap regularly

– Inspect vacuum hoses for cracks or leaks

– Change the fuel filter every 30,000 miles

– Keep the engine air filter clean

– Use quality fuel and avoid contaminated gas

Regular maintenance not only prevents warning lights but also extends the life of your vehicle.

When to See a Mechanic

While jumping the ALDL is a great DIY tool, some issues require professional attention. If you’re unsure about the codes, the repair seems complex, or the light keeps coming back, don’t hesitate to visit a trusted mechanic. They have advanced tools and expertise to diagnose and fix stubborn problems.

Common Mistakes to Avoid

Even experienced DIYers can make mistakes when jumping the ALDL. Here are some common pitfalls and how to avoid them.

Using the Wrong Terminals

Jumping the wrong pins can cause inaccurate readings or damage the ECM. Always double-check that you’re connecting Pin A and Pin B.

Starting the Engine

Never start the engine while the jumper is in place. This can send incorrect signals to the ECM and potentially damage sensors.

Ignoring Safety

Always wear safety glasses and work in a well-lit area. Avoid loose clothing or jewelry that could get caught in moving parts.

Misreading Flash Codes

Count flashes carefully. It’s easy to miscount, especially with fast or slow flashes. Use a pen and paper to record each code as it appears.

Assuming the Light is Harmless

While some codes are minor, others indicate serious issues. Don’t ignore the check engine light—address it promptly to avoid costly repairs.

Conclusion

Jumping the ALDL in your 1994 Oldsmobile 98 is a simple, effective way to read and clear check engine light codes without expensive tools. By following the steps in this guide, you can diagnose common issues, verify repairs, and keep your classic car running smoothly.

Remember, the key is patience and attention to detail. Locate the correct terminals, use a safe jumper, and interpret the flash codes accurately. And when in doubt, don’t hesitate to consult a professional.

With regular maintenance and a little know-how, your 1994 Olds 98 can continue to deliver reliable performance for years to come. So the next time that check engine light comes on, you’ll know exactly what to do—no scanner required.

Frequently Asked Questions

Can I use a scanner instead of jumping the ALDL?

Yes, but most OBD-II scanners won’t work with a 1994 Olds 98 because it uses an older OBD-I system. You’d need a compatible OBD-I scanner or the manual jumping method described here.

Will jumping the ALDL damage my car?

No, if done correctly. Using a paperclip to connect Pin A and Pin B is safe and won’t harm the ECM or wiring. Just avoid forcing the jumper or using metal tools.

What if no codes appear when I jump the ALDL?

If the check engine light doesn’t flash, the jumper may not be making proper contact. Recheck the pins and ensure the ignition is on (engine off). Code 12 may appear if the system is functioning normally.

Can I clear the check engine light without fixing the problem?

Yes, jumping the ALDL will clear the codes, but the light will likely return if the underlying issue isn’t repaired. It’s best to diagnose and fix the problem first.

How often should I check for trouble codes?

Only when the check engine light comes on. There’s no need for routine checks unless you’re troubleshooting a performance issue.

Is it safe to drive with the check engine light on?

It depends on the code. Minor issues like a loose gas cap may be safe to drive with temporarily, but serious codes (e.g., engine misfire) should be addressed immediately to prevent damage.