Discover how to diagnose and reset the check engine light on your 1993 Ford F150 using built-in OBD-I diagnostics, a paperclip method, and basic tools. This guide simplifies the process for classic truck owners in 2026.

Key Takeaways

- Understand OBD-I System Basics: The 1993 Ford F150 uses an older OBD-I system, which requires manual code retrieval instead of modern OBD-II scanners.

- Use the Paperclip Method: You can read trouble codes by bridging two pins in the diagnostic connector with a paperclip and counting the check engine light flashes.

- Locate the Diagnostic Port: The DLC (Data Link Connector) is typically under the driver’s side dashboard near the steering column.

- Interpret Flash Patterns: Each code is displayed as a series of long and short flashes—learn how to decode them accurately.

- Common Issues Include: Faulty oxygen sensors, vacuum leaks, ignition problems, and emissions system faults.

- Clear Codes Manually: After repairs, disconnect the battery for 10–15 minutes to reset the ECU and turn off the light.

- Seek Professional Help When Needed: If codes persist or you’re unsure, consult a mechanic familiar with older Ford trucks.

How to Check Engine Light 93 Ford F150: A Complete 2026 Guide

If you’re driving a classic 1993 Ford F150 in 2026, you’re part of a proud community of truck enthusiasts who value durability, simplicity, and hands-on maintenance. But when that dreaded check engine light pops up, it can feel like a mystery—especially since modern OBD-II scanners won’t work on your older OBD-I system. Don’t worry! This guide will walk you through exactly how to check the engine light on a 93 Ford F150 using proven, DIY-friendly methods. Whether you’re troubleshooting a rough idle, poor fuel economy, or just want peace of mind, you’ll learn how to read trouble codes, interpret them, and take action—all without expensive tools or a trip to the shop.

By the end of this guide, you’ll know how to access your truck’s onboard diagnostics, decode flash patterns, identify common issues, and even reset the light after repairs. We’ll also cover safety tips, troubleshooting advice, and when it’s time to call in a professional. So grab your flashlight, a paperclip, and let’s get started!

Understanding the 1993 Ford F150’s OBD-I System

Before diving into the steps, it’s important to understand what makes the 1993 Ford F150 different from newer vehicles. Unlike modern trucks that use the standardized OBD-II (On-Board Diagnostics II) system—which allows any generic scanner to read codes—the 1993 F150 uses the older OBD-I system. This means:

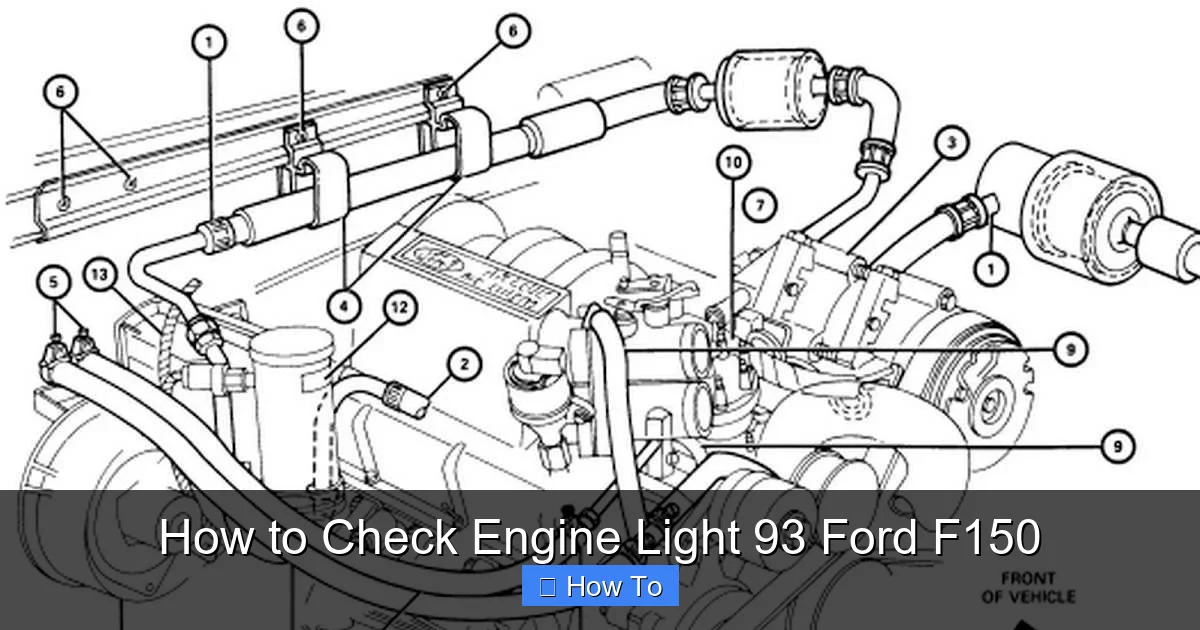

Visual guide about How to Check Engine Light 93 Ford F150

Image source: wiringall.com

- There’s no universal OBD-II port under the dash.

- Diagnostic trouble codes (DTCs) are stored in the engine control module (ECM) but must be read manually.

- The system is less sophisticated but still effective for identifying major engine and emissions issues.

The OBD-I system in your F150 is designed to monitor key components like the oxygen sensor, EGR valve, ignition system, and fuel delivery. When a fault is detected, the ECM triggers the check engine light and stores a numeric code. Your job is to retrieve that code—and that’s where the paperclip method comes in.

Tools and Materials You’ll Need

One of the best things about diagnosing a 1993 F150 is how little you need. Here’s what to gather before starting:

- A paperclip or small jumper wire: Straightened out, about 3–4 inches long.

- A flashlight: To help you see under the dashboard.

- A notepad and pen: To record the flash patterns and codes.

- Basic hand tools (optional): Screwdriver or socket set if you need to access components later.

- Patience and focus: Reading flash codes requires attention to detail.

That’s it! No expensive scan tools or software. This method has been used by Ford owners for decades and still works perfectly in 2026.

Step-by-Step: How to Read Check Engine Light Codes on a 93 Ford F150

Step 1: Locate the Diagnostic Link Connector (DLC)

The first step is finding the Data Link Connector (DLC), also known as the diagnostic port. On the 1993 Ford F150, it’s located under the driver’s side dashboard, near the steering column. You’ll typically find it clipped to a bracket or tucked behind the kick panel.

Look for a small, rectangular connector with 6 pins arranged in two rows of three. It may be labeled “DIAGNOSTIC” or have a small cover. If you can’t find it, check near the fuse box or behind the lower dash panel. Use your flashlight to get a clear view.

Step 2: Prepare the Paperclip Jumper

Take a standard paperclip and straighten it out so you have a straight piece of metal wire. You can also use a small jumper wire with alligator clips if you have one, but a paperclip works just as well.

The goal is to create a temporary bridge between two specific pins in the DLC. For the 1993 F150, you’ll be connecting Pin A (the top-left pin) and Pin B (the top-right pin) when facing the connector. These are the “Self-Test Input” and “Signal Ground” pins, respectively.

Double-check the pin layout using a Ford OBD-I diagram if you’re unsure. Incorrect connections won’t damage the system, but they won’t trigger the code readout either.

Step 3: Turn the Ignition to “On” (But Don’t Start the Engine)

Insert the key into the ignition and turn it to the “ON” position. This powers up the electrical system and the ECM, but the engine should remain off. You’ll see dashboard lights illuminate, including the check engine light.

At this point, the check engine light should be on. If it’s not, there may be a bulb issue or the ECM isn’t receiving power—check fuses if needed.

Step 4: Insert the Paperclip and Wait for Flashes

Carefully insert one end of the paperclip into Pin A and the other end into Pin B. Make sure the metal makes solid contact—wiggle it gently if needed.

Within a few seconds, the check engine light will begin to flash. These flashes represent diagnostic trouble codes (DTCs) in a binary-like pattern. Each code consists of a series of long and short flashes.

For example:

- A long flash = “10”

- A short flash = “1”

So, two long flashes followed by three short flashes would be Code 23.

Step 5: Record the Flash Pattern

Watch the check engine light carefully and write down the sequence. Codes are usually displayed in groups, with a pause between each code. The system may repeat the sequence multiple times.

Common patterns include:

- Code 12: One long flash, two short flashes (indicates the system is working normally at startup).

- Code 13: One long, three short (oxygen sensor circuit issue).

- Code 44: Four long, four short (EGR system problem).

If multiple codes appear, record them all. The system will cycle through stored faults, so be patient.

Step 6: Interpret the Codes

Once you’ve recorded the flash pattern, it’s time to decode it. Use a 1993 Ford F150 OBD-I code chart (available online or in repair manuals) to identify what each code means.

Here are a few common codes and their meanings:

- Code 11: No RPM signal (crankshaft position sensor issue).

- Code 14: Ignition pickup fault.

- Code 15: Throttle position sensor (TPS) out of range.

- Code 17: Engine coolant temperature (ECT) sensor problem.

- Code 21: ECT sensor circuit open or shorted.

- Code 32: EGR valve not opening (common on older Fords).

- Code 41: Oxygen sensor indicates lean condition.

- Code 51: System lean (vacuum leak or fuel delivery issue).

- Code 54: Canister purge valve stuck open.

- Code 63: Throttle position sensor voltage too high.

Some codes may seem vague, but they point you in the right direction. For example, Code 41 suggests a lean mixture, which could be caused by a vacuum leak, dirty fuel injector, or faulty O2 sensor.

Common Issues Behind the Check Engine Light on a 93 F150

Now that you know how to read the codes, let’s look at the most frequent culprits behind the check engine light in a 1993 Ford F150. These trucks are built to last, but certain components wear out over time—especially after 30+ years.

1. Oxygen (O2) Sensor Failure

The O2 sensor monitors exhaust gas oxygen levels and helps the ECM adjust the air-fuel mixture. A faulty sensor can cause poor fuel economy, rough idle, and increased emissions. Codes like 13, 41, or 42 often point to this issue.

Solution: Replace the O2 sensor. On the 93 F150, it’s usually located in the exhaust manifold or downpipe. Use an O2 sensor socket and anti-seize compound for easier future removal.

2. Vacuum Leaks

Vacuum leaks are a classic problem in older trucks. Cracked hoses, loose connections, or a leaking intake manifold gasket can cause a lean condition (Code 51) or erratic idle.

Solution: Inspect all vacuum lines for cracks, brittleness, or disconnections. Use a vacuum gauge or spray carb cleaner around suspected areas—if the engine RPM changes, you’ve found a leak.

3. EGR Valve Issues

The Exhaust Gas Recirculation (EGR) valve reduces NOx emissions by recirculating a small amount of exhaust gas into the intake. Over time, it can get clogged with carbon (Code 32 or 44).

Solution: Remove the EGR valve and clean it with carburetor cleaner. If it’s stuck open or closed, replacement may be necessary.

4. Throttle Position Sensor (TPS) Problems

The TPS tells the ECM how far the throttle is open. A faulty TPS (Codes 15, 63) can cause hesitation, stalling, or poor acceleration.

Solution: Test the TPS with a multimeter for proper voltage output. Adjust or replace if out of spec.

5. Ignition System Faults

Worn spark plugs, bad plug wires, or a failing distributor can trigger codes like 14 or 11. These issues lead to misfires and reduced performance.

Solution: Replace spark plugs and wires every 30,000–50,000 miles. Inspect the distributor cap and rotor for wear or carbon tracking.

6. Fuel Delivery Issues

A weak fuel pump, clogged fuel filter, or dirty injectors can cause lean codes or hesitation. The 93 F150 uses a return-style fuel system, so pressure should be around 35–45 psi.

Solution: Test fuel pressure with a gauge. Replace the fuel filter every 20,000 miles and consider using a fuel system cleaner.

How to Clear the Check Engine Light on a 93 Ford F150

After diagnosing and fixing the issue, you’ll want to turn off the check engine light. Unlike modern vehicles, the 93 F150 doesn’t have a “clear codes” button. Instead, you’ll need to reset the ECM manually.

Method 1: Disconnect the Battery

The most common way to clear codes is to disconnect the negative battery terminal for 10–15 minutes. This resets the ECM’s memory and turns off the light.

Steps:

- Turn off the ignition and remove the key.

- Use a wrench to loosen the negative battery cable.

- Disconnect the cable and wait at least 10 minutes.

- Reconnect the cable and tighten securely.

- Turn the ignition back on—the light should be off.

Note: This method also resets radio presets, clock, and other memory settings. Be prepared to reprogram them.

Method 2: Drive Cycle Reset

In some cases, the ECM will clear the code automatically after a certain number of error-free drive cycles. This typically involves driving under various conditions (idle, acceleration, cruising) for 30–50 miles.

However, if the underlying issue isn’t fixed, the light will return. Always address the root cause before relying on a drive cycle reset.

Troubleshooting Tips and Common Mistakes

Even with the right steps, things can go wrong. Here are some tips to avoid frustration:

1. The Light Doesn’t Flash

If the check engine light doesn’t flash after inserting the paperclip, double-check:

- The ignition is in the “ON” position.

- The paperclip is making solid contact with Pins A and B.

- The DLC connector isn’t damaged or corroded.

- The check engine bulb isn’t burned out.

If all else fails, try wiggling the paperclip or using a different jumper wire.

2. You Get Code 12 Repeatedly

Code 12 (one long, two short flashes) is a normal startup code. It means the system is functioning and no hard faults are present. If it’s the only code, your truck may be running fine—just keep an eye on performance.

3. The Light Comes Back On

If the light returns after clearing, the problem wasn’t fully resolved. Recheck your repair and consider testing related sensors or circuits.

4. You’re Not Sure What a Code Means

Don’t guess! Use a reliable OBD-I code chart for 1993 Ford trucks. Websites like Ford-Trucks.com or repair manuals like Haynes or Chilton are excellent resources.

When to Call a Professional

While the 93 F150 is very DIY-friendly, some issues require advanced tools or expertise. Consider seeking help if:

- You get a code you can’t interpret or fix.

- The problem involves internal engine components (e.g., timing, compression).

- You suspect electrical issues beyond basic sensors.

- The truck has persistent drivability problems despite repairs.

A mechanic familiar with older Ford trucks can perform a deeper diagnosis using specialized equipment and experience.

Maintaining Your 93 F150 to Prevent Future Issues

Prevention is key to avoiding check engine light surprises. Here are some maintenance tips for 2026 owners:

- Replace the O2 sensor every 60,000–100,000 miles.

- Inspect vacuum lines annually for cracks or leaks.

- Clean the EGR valve and passages every 30,000 miles.

- Use quality fuel and additives to keep injectors clean.

- Check and replace spark plugs and wires as needed.

- Keep the air filter clean to ensure proper airflow.

Regular maintenance not only prevents check engine lights but also extends the life of your classic truck.

Conclusion

Checking the engine light on a 1993 Ford F150 doesn’t have to be intimidating. With the paperclip method, a little patience, and this guide, you can read diagnostic codes, identify common issues, and take action—all from your driveway in 2026. Whether you’re dealing with an O2 sensor, vacuum leak, or EGR problem, knowing how to interpret the check engine light empowers you to keep your truck running strong.

Remember: the OBD-I system may be outdated, but it’s reliable and accessible. Use the steps above to stay informed, save money on diagnostics, and enjoy the satisfaction of hands-on truck ownership. And if you ever get stuck, the classic Ford community is full of helpful owners ready to share advice.

So the next time that little orange light comes on, don’t panic—grab your paperclip, decode the message, and get back on the road with confidence.