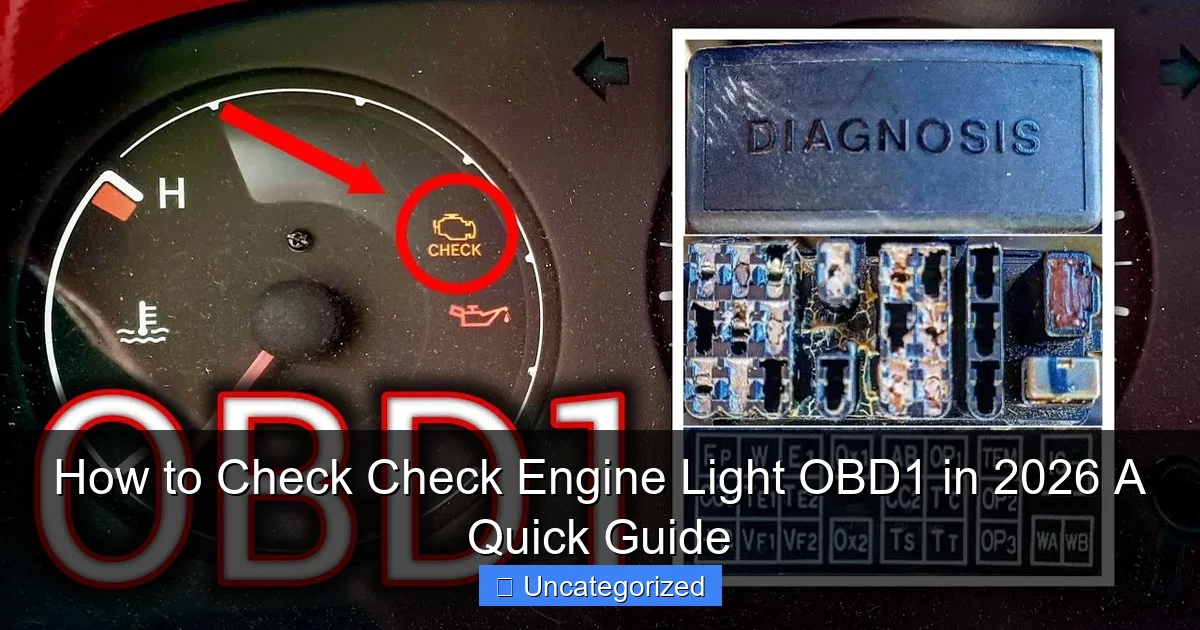

Featured image for how to check check engine light obd1

Image source: i.ytimg.com

Diagnose your OBD1 check engine light in seconds using the ignition key’s “on-off-on-off-on” sequence to trigger flash codes. This quick, no-tool method reveals vital trouble codes stored in your 2026 vehicle’s ECU, letting you identify issues like misfires or sensor failures instantly. Master this simple hack to save time, avoid mechanic fees, and keep your ride running smoothly.

How to Check Check Engine Light OBD1 in 2026: A Quick Guide

Key Takeaways

- Locate the DLC: Find the OBD1 port under the dashboard near the steering column.

- Use a paperclip: Bridge terminals to trigger diagnostic trouble code flashes.

- Count the flashes: Each code corresponds to a specific vehicle issue.

- Refer to the manual: Match codes to problems using your vehicle’s service guide.

- Address urgent codes: Prioritize repairs for codes causing performance issues.

- Reset after repairs: Clear codes by disconnecting the battery briefly.

Why This Matters / Understanding the Problem

Your car’s check engine light (CEL) is like its nervous system—when it flickers on, something’s off. But if you’re driving an older vehicle (pre-1996), you’re dealing with OBD1 (On-Board Diagnostics 1), not the modern OBD2 systems everyone talks about today.

Unlike newer cars with universal scanners, OBD1 systems are manufacturer-specific and often require a bit of DIY magic to decode. That’s why knowing how to check check engine light OBD1 in 2026 a quick guide is still valuable—even in the future, classic cars and budget-friendly older models remain on the road.

Ignoring the CEL can lead to bigger problems: poor fuel economy, engine damage, or even failing emissions tests. The good news? You don’t need a mechanic to read OBD1 codes. With a few minutes and basic tools, you can uncover what’s bugging your ride—and fix it before it becomes a costly repair.

This guide walks you through every step, from identifying your system to clearing codes, using real-world examples. Whether you drive a 1985 Toyota pickup or a 1994 Ford Ranger, this method works. And yes, it’s still relevant in 2026, especially as more people keep older, reliable vehicles running.

What You Need

Don’t worry—you won’t need a fancy $300 scanner or a computer science degree. Most OBD1 systems were designed for DIY diagnostics long before smartphones existed.

Visual guide about how to check check engine light obd1

Image source: i.ytimg.com

Here’s your quick checklist for how to check check engine light OBD1 in 2026 a quick guide:

- Jumper wire (or a paperclip): To bridge the diagnostic terminal. Any insulated wire (12–18 inches) works.

- Flashlight: Helps see under the dash in dim lighting.

- Notepad and pen: To jot down the flash codes (or use your phone’s Notes app).

- Vehicle service manual (optional): For code definitions. Free PDFs are available online for most models.

- Owner’s manual: Locates the diagnostic connector (usually under the dash near the steering column).

- Patience: Some codes take time to cycle. Don’t rush!

Pro Tip: No jumper wire? A straightened paperclip works just as well. Just make sure it’s clean and straight so it fits snugly into the connector.

Unlike OBD2, you don’t need an app or Wi-Fi. OBD1 uses flash codes—the check engine light blinks in sequences to tell you the problem. For example, two short blinks followed by a long blink might mean “code 21,” which could point to a coolant sensor issue.

Step-by-Step Guide to How to Check Check Engine Light OBD1 in 2026 A Quick Guide

Step 1: Confirm You Have an OBD1 System

Before you start, make sure your vehicle actually uses OBD1. This system was standard from the late 1980s to 1995 in the U.S. (1996+ vehicles use OBD2).

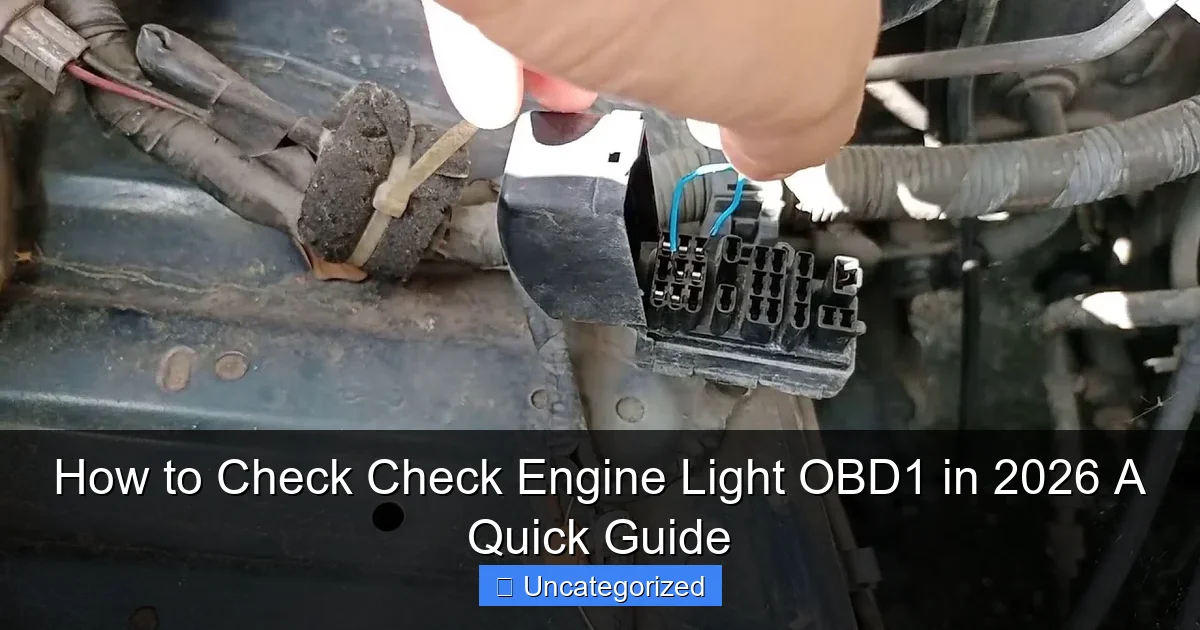

Visual guide about how to check check engine light obd1

Image source: i.ytimg.com

Check your model and year:

- 1981–1995: Most domestic (Ford, GM, Chrysler) and Japanese (Toyota, Honda, Nissan) cars used OBD1.

- 1996 and newer: OBD2 is federally mandated. If your car was built after 1995, skip this guide—it won’t work.

Look for the diagnostic connector under the driver’s side dashboard. OBD1 connectors vary by brand but are usually a 6- or 12-pin rectangular block. For example:

- GM: ALDL (Assembly Line Diagnostic Link), 12-pin.

- Ford: 6-pin rectangular connector, often labeled “Test.”

- Honda/Acura: 3-pin connector under the hood or under the dash.

Warning: Don’t confuse the OBD1 connector with the OBD2 port (a 16-pin trapezoid shape). If you see that, your car is post-1995 and uses OBD2.

Once you’ve confirmed OBD1, you’re ready for the next step. Remember, knowing your system is the first key to mastering how to check check engine light OBD1 in 2026 a quick guide.

Step 2: Locate and Identify the Diagnostic Terminal

Now, find the exact spot to plug in your jumper wire. The terminal location varies, but here are common setups:

- GM (1982–1995): 12-pin ALDL connector under the dash. Look for pins labeled “A” and “B” (or “1” and “2”).

- Ford (1984–1995): 6-pin connector near the steering column. Pins “1” and “2” are used for diagnostics.

- Honda (1986–1995): 3-pin connector under the hood (near the battery) or under the dash. Use pins “1” and “2.”

- Toyota (1984–1995): 12-pin OBD1 connector under the dash. Pins “TE1” and “E1” are key.

Use your owner’s manual or a quick online search (e.g., “1990 Ford F-150 OBD1 connector location”) to find the exact pins. Some connectors have labels; others require a diagram.

Once you’ve found it, clean the connector gently with a dry cloth. Dirt or corrosion can interfere with the connection.

Pro Tip: Take a photo of the connector and pins with your phone. It helps you remember where to jump, especially if you’re doing this for the first time.

This step is crucial—misidentifying the pins can lead to incorrect or no codes. Double-check your model’s diagram before proceeding.

Step 3: Jump the Diagnostic Connector

Now comes the “magic” part—bridging the right pins to trigger the flash codes.

Here’s how to do it safely and correctly:

- Turn the ignition OFF. Make sure the engine is not running.

- Insert the jumper wire (or paperclip) into the two correct pins. For example:

- GM: Jump pins “A” and “B.”

- Ford: Jump pins “1” and “2.”

- Honda: Jump pins “1” and “2” (or “+” and “-”).

- Toyota: Jump “TE1” and “E1.”

- Turn the ignition to “ON” (RUN position). Do NOT start the engine. You should see the check engine light come on.

- Wait 3–5 seconds. The light will stay solid for a moment, then begin flashing.

The check engine light will now blink in a sequence. Each blink pattern represents a code. For example:

- One long flash (1 second) + two short flashes (0.5 seconds each) = code 12.

- Two long flashes + one short flash = code 21.

Warning: Keep the jumper in place the whole time. Removing it too early will interrupt the code sequence and force you to restart.

Some systems (like Ford) use a “double pulse” for tens—so code 23 is two long blinks, a pause, then three short blinks. Pay close attention to the rhythm.

Step 4: Read and Record the Flash Codes

Now, focus on the check engine light. It will cycle through multiple codes, usually in order. Each code has:

- Long flashes (1 second): Represent the tens digit.

- Short flashes (0.5 seconds): Represent the ones digit.

- Pauses (2–3 seconds): Separate each code.

Example: You see:

- One long blink + two short blinks → 12 (common “no RPM signal” code).

- Pause (3 seconds) → Two long blinks + one short blink → 21 (e.g., coolant sensor issue).

Write down each code as it appears. Some systems repeat codes 2–3 times. After all codes are shown, the system may cycle again or return to a steady light.

Pro Tip: Use your phone to record a video of the flashing light. Play it back in slow motion if you miss a code. This is especially helpful for fast or complex sequences.

Common codes vary by manufacturer:

- GM: Code 12 = “No RPM signal” (engine not running). Code 44 = lean exhaust.

- Ford: Code 11 = “System pass.” Code 41 = oxygen sensor issue.

- Honda: Code 1 = oxygen sensor. Code 6 = coolant temp sensor.

- Toyota: Code 22 = water temp sensor. Code 41 = throttle position sensor.

Record all codes—even if they seem minor. Multiple codes can point to a root cause (e.g., a bad sensor triggering others).

Step 5: Interpret the Codes

Now, decode what those numbers mean. Don’t guess—use a reliable source.

Here’s where your service manual or online database comes in. Search for:

- “1992 Ford F-150 OBD1 code 21”

- “1988 Honda Civic OBD1 code 6”

- “1990 Toyota Camry OBD1 code 22”

Free resources include:

- OBD1 Code Lists on forums: Sites like Reddit, Ford Truck Enthusiasts, or Honda-Tech have user-generated tables.

- YouTube tutorials: Search “read OBD1 codes [your model].”

- Haynes or Chilton manuals: Available as PDFs or physical books.

Example: If you get code 21 on a Ford:

- It often means the coolant temperature sensor is out of range.

- Symptoms: Hard cold starts, poor fuel economy, or overheating.

- Fix: Test the sensor with a multimeter or replace it (usually $20–$40).

Pro Tip: Not all codes mean “replace part.” Some are intermittent. Clear the code (Step 7), drive the car, and see if it returns. If it doesn’t, it might have been a one-time glitch.

Understanding the codes is the heart of how to check check engine light OBD1 in 2026 a quick guide—it turns a mystery light into actionable info.

Step 6: Prioritize and Plan Your Fix

Not all codes are urgent. Some are warnings; others are critical.

Use this priority system:

- Critical (Fix Now):

- Code 14 (GM): Ignition coil failure—car may stall.

- Code 43 (Ford): Knock sensor—can damage engine over time.

- Moderate (Fix Soon):

- Code 21 (Ford): Coolant sensor—affects fuel mix.

- Code 1 (Honda): O2 sensor—lowers fuel economy.

- Low Priority (Monitor):

- Code 12 (GM): “No RPM signal”—only appears with engine off. Harmless.

- Code 11 (Ford): “System pass”—means no current faults.

Create a repair plan:

- List all codes and their meanings.

- Sort by urgency.

- Check parts prices and difficulty (YouTube “how to replace [part]”).

- Buy or borrow tools if needed.

Example: You have codes 21 (coolant sensor) and 41 (O2 sensor). Start with the coolant sensor—it’s cheaper and easier to replace. Then tackle the O2 sensor if the light returns.

Step 7: Clear the Codes (Optional)

After diagnosing, you may want to clear the codes to see if the problem returns.

Methods vary by manufacturer:

- GM/Ford: Turn ignition OFF, remove the ECU fuse (usually in the under-hood fuse box) for 10–15 seconds. Reinsert.

- Honda/Toyota: Disconnect the negative battery cable for 5–10 minutes. Reconnect.

After clearing:

- Start the car and let it idle for 5 minutes.

- Take a 10–15 minute drive (include city and highway speeds).

- Check if the light returns.

Warning: Clearing codes doesn’t fix the problem. If the issue isn’t resolved, the light will come back. Use this step to test repairs, not hide symptoms.

Note: Some OBD1 systems store “pending” codes. Clearing may not erase them until the issue is fixed.

Pro Tips & Common Mistakes to Avoid

Even simple OBD1 diagnostics can go wrong if you rush. Here’s how to avoid the pitfalls:

Use the Right Pins (Not Just Any Two)

One of the biggest mistakes? Jumping the wrong pins. For example, on a GM ALDL connector, jumping “A” to “C” won’t trigger codes—it might even confuse the ECU.

Pro Tip: Label your jumper wire with tape (“A to B”) to avoid mix-ups. Keep a cheat sheet in your glove box.

Don’t Start the Engine While Jumping

OBD1 flash codes only work in the “ignition ON, engine OFF” state. If you start the car, the light will go out and stop flashing.

Some mechanics try to jump while cranking—this rarely works and can damage sensors.

Wait for All Codes to Cycle

Some systems take 2–3 minutes to show all codes. Don’t assume the first code is the only one. Wait until the light goes steady or repeats the sequence.

Verify with a Manual (Don’t Rely on Memory)

Code meanings change by model and year. A “code 21” on a 1989 Honda might mean a different thing than on a 1995 Honda. Always check a current source.

Check for Multiple Issues

One bad sensor can trigger others. For example, a faulty coolant sensor can cause the ECU to misread fuel mix, leading to false O2 sensor codes. Fix the root cause first.

Don’t Ignore “Intermittent” Codes

Codes like “12” (GM) or “11” (Ford) appear only when the system checks itself (ignition on, no RPM). They’re normal—don’t panic!

Keep the Battery Charged

Low voltage can cause false codes or prevent the ECU from storing them. If your battery is weak, charge it before diagnosing.

FAQs About How to Check Check Engine Light OBD1 in 2026 A Quick Guide

Q1: Can I use an OBD2 scanner on an OBD1 car?

Nope. OBD1 and OBD2 are different systems. An OBD2 scanner won’t connect to a 1995 or older car’s port. However, some adapters exist (like the Equus 3145), but they’re not universal. For most OBD1 cars, flash codes are the easiest and cheapest method.

Q2: What if the check engine light doesn’t flash?

Check these first:

- Is the jumper wire secure?

- Are you using the correct pins?

- Is the ignition in the “ON” position (not “ACC”)?

- Is the battery charged?

If none work, the ECU or check engine light bulb may be faulty.

Q3: Can I check OBD1 codes without a jumper wire?

Some systems have a “test mode” button or a diagnostic switch (e.g., older Hondas). But most require a jumper. A paperclip is a free, effective alternative.

Q4: Do OBD1 codes reset automatically?

Not always. Some codes clear after 50–100 ignition cycles if the problem is fixed. Others stay until manually cleared. Clearing helps confirm if a repair worked.

Q5: Are OBD1 codes the same for all brands?

No. Each manufacturer has its own code set. A “code 1” on a Honda means an oxygen sensor issue; on a GM, it means “no RPM signal.” Always use brand-specific resources.

Q6: Can I clear OBD1 codes by disconnecting the battery?

Yes, but it also resets radio presets, clock, and sometimes the ECU’s “learned” fuel trim. Use this method only if other options fail. A fuse pull is cleaner.

Q7: Is this method safe for my car?

Yes. Jumping the diagnostic connector is how mechanics and manufacturers designed OBD1 diagnostics. Just don’t leave the jumper in after reading codes—it can drain the battery.

🎥 Related Video: Check Engine Light / Limp Mode Reset Without A Scanner, How to

📺 The Clay Way

So my transmission was in limp mode when I picked this vehicle up, so I wanted to reset that limp mode without a scanner. I figure …

Final Thoughts

Knowing how to check check engine light OBD1 in 2026 a quick guide is like having a secret tool in your garage. It empowers you to diagnose problems without a mechanic’s bill, save money, and keep your older car running smoothly.

You don’t need tech skills or expensive gear. Just a jumper wire, a flashlight, and a few minutes. Whether you’re a classic car enthusiast or just trying to stretch your budget, this skill pays off.

Remember: the check engine light is a warning, not a death sentence. With OBD1 flash codes, you’re not just reacting—you’re in control.

Action Step: Next time your CEL comes on, grab your tools and try this method. Write down the codes, research them, and fix the issue. Share your success story with a friend. The more people who know this trick, the more older cars stay on the road where they belong.

Keep your ride running, save cash, and enjoy the satisfaction of solving your car’s mystery—one flash at a time.