This guide walks you through the process of connecting LED wires to an LED engine light, ensuring a safe, reliable, and professional-looking installation. You’ll learn about tools, wiring basics, step-by-step connections, and troubleshooting tips to avoid common mistakes.

Key Takeaways

- Use the right tools: A wire stripper, soldering iron, heat shrink tubing, and multimeter are essential for a clean and secure connection.

- Match polarity correctly: LEDs are polarity-sensitive—connect the positive (anode) and negative (cathode) wires to the correct terminals to avoid damage.

- Follow your vehicle’s wiring diagram: Always refer to your car’s manual or a reliable diagram to identify the correct engine light circuit.

- Solder for durability: Soldering connections ensures a strong, long-lasting bond compared to twist-on connectors.

- Test before finalizing: Always test the LED before securing everything in place to catch issues early.

- Use heat shrink tubing: This protects soldered joints from moisture, vibration, and short circuits.

- Check for CAN bus compatibility: Some modern vehicles require CAN bus-compatible LEDs to prevent error messages.

How to Connect LED Wires to LED Engine Light

Upgrading your vehicle’s engine light to an LED can improve visibility, reduce power consumption, and give your dashboard a modern look. However, connecting LED wires to an LED engine light isn’t as simple as just plugging it in—especially if you’re replacing a traditional incandescent bulb or installing a custom setup. This guide will walk you through the entire process, from gathering tools to testing your final connection. Whether you’re a DIY car enthusiast or a beginner, you’ll finish with a safe, reliable, and professional-looking installation.

We’ll cover everything you need to know: identifying the right wires, understanding polarity, soldering techniques, and troubleshooting common issues. By the end, you’ll be confident in your ability to connect LED wires to your engine light without frying the circuit or triggering warning messages on your dashboard.

What You’ll Need

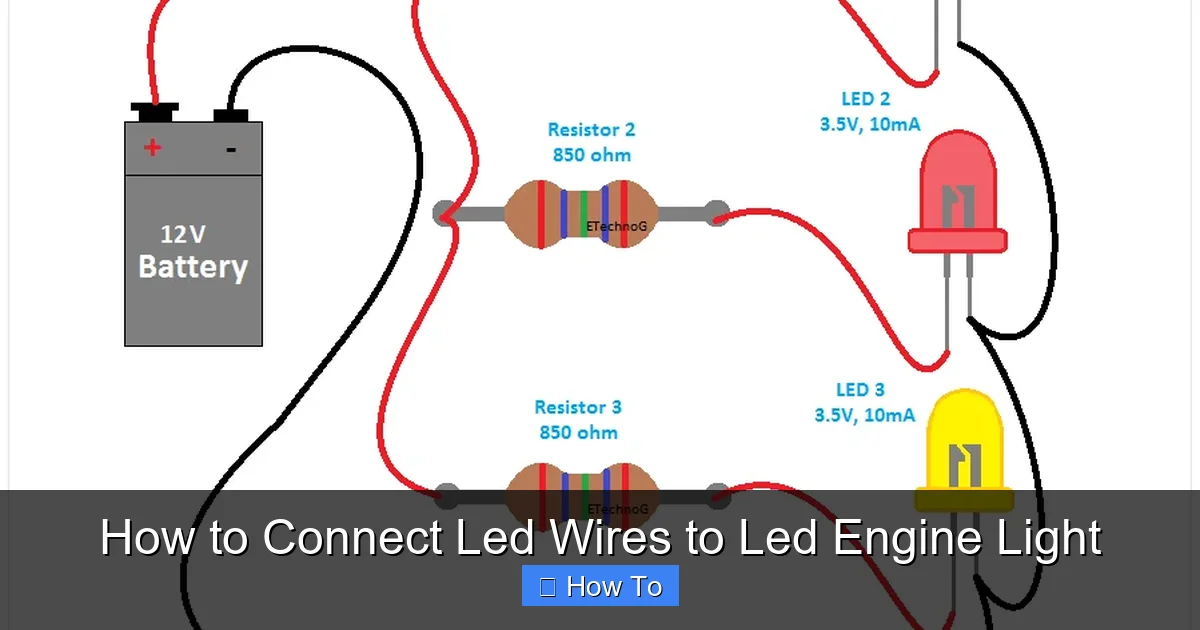

Visual guide about How to Connect Led Wires to Led Engine Light

Image source: i1.wp.com

Before starting, make sure you have the right tools and materials. Skipping this step can lead to frustration, damaged components, or unsafe connections.

Essential Tools

- Wire strippers: For cleanly removing insulation from wires without damaging the copper.

- Soldering iron and solder: For creating strong, permanent connections.

- Heat shrink tubing: To insulate and protect soldered joints.

- Multimeter: To test voltage, continuity, and polarity.

- Electrical tape: As a backup insulator if heat shrink isn’t available.

- Wire connectors (optional): If you prefer not to solder, use crimp connectors—but soldering is recommended.

Materials

- LED engine light (compatible with your vehicle)

- Automotive-grade wire (18-22 AWG recommended)

- Fuse tap (if tapping into a fused circuit)

- Zip ties or wire loom (for neat cable management)

Safety Gear

- Safety glasses

- Gloves (optional, but helpful when handling sharp wires)

Step 1: Disconnect the Battery

Safety first! Always disconnect the negative terminal of your car battery before working on any electrical system. This prevents accidental shorts, sparks, or damage to your vehicle’s electronics.

How to Disconnect the Battery

- Open the hood and locate the battery.

- Use a wrench to loosen the nut on the negative (black) terminal.

- Remove the cable and secure it away from the battery terminal with a zip tie or tape.

Tip: Wait 10–15 minutes after disconnecting the battery to allow residual power to drain from the vehicle’s systems.

Step 2: Locate the Engine Light Socket

The engine light (also known as the check engine light) is typically located on the instrument cluster behind the dashboard. You’ll need to access the back of the cluster to reach the bulb socket.

Accessing the Instrument Cluster

- Remove the dashboard trim carefully using a trim removal tool or flathead screwdriver (wrap the tip in tape to avoid scratches).

- Unscrew or unclip the instrument cluster and gently pull it forward.

- Locate the engine light bulb socket—it’s usually labeled or identifiable by its position.

Note: Some vehicles require removing the steering column cover or glove box for better access. Consult your vehicle’s service manual if unsure.

Step 3: Identify the Wiring and Polarity

LEDs are polarity-sensitive, meaning they only work when connected correctly. Reversing the wires can damage the LED or prevent it from lighting up.

Using a Multimeter to Test Polarity

- Set your multimeter to DC voltage (usually marked as “V⎓”).

- Reconnect the battery temporarily (just for testing—disconnect again afterward).

- Touch the red probe to one wire and the black probe to the other.

- If the reading is positive, the red probe is on the positive wire. If negative, the polarity is reversed.

Tip: Most automotive circuits use black for ground (negative) and colored wires (red, yellow, green) for positive. But always verify with a multimeter—don’t rely on color alone.

Step 4: Prepare the LED and Wires

Now it’s time to prepare your LED and connect it to the vehicle’s wiring.

Strip the Wires

- Use wire strippers to remove about 1/2 inch of insulation from the ends of both the vehicle’s wires and the LED leads.

- Twist the exposed copper strands to keep them neat.

Identify LED Polarity

- The longer lead on the LED is the anode (positive).

- The shorter lead is the cathode (negative).

- Some LEDs also have a flat side on the base—this indicates the cathode.

Match Polarity

Ensure the LED’s anode connects to the positive wire and the cathode to the negative wire. Reversing this will prevent the LED from working.

Step 5: Connect the Wires

There are two main ways to connect the wires: soldering (recommended) or using crimp connectors. We’ll focus on soldering for durability.

Soldering the Connection

- Hold the stripped ends of the vehicle wire and LED lead together.

- Heat the joint with the soldering iron for 2–3 seconds.

- Touch the solder to the joint (not the iron) until it melts and flows around the wires.

- Remove the iron and let the joint cool for 10–15 seconds.

Tip: Use rosin-core solder designed for electronics—avoid acid-core solder, which can corrode wires.

Insulate with Heat Shrink Tubing

- Slide a piece of heat shrink tubing over the soldered joint before soldering (do this beforehand!).

- After soldering, slide the tubing over the joint.

- Use a heat gun or lighter to shrink the tubing, creating a tight, waterproof seal.

Alternative: If you don’t have heat shrink, wrap the joint tightly with electrical tape—but this is less durable.

Step 6: Test the LED

Before reassembling everything, test the LED to make sure it works.

How to Test

- Reconnect the battery temporarily.

- Turn on the ignition (do not start the engine).

- Check if the engine light illuminates.

- If it doesn’t light up, double-check polarity and connections.

Note: Some vehicles run a bulb check at startup—your LED should light up briefly when you turn the key to “ON.”

Step 7: Secure and Reassemble

Once the LED works, secure the wiring and reassemble the dashboard.

Cable Management

- Use zip ties to bundle wires neatly.

- Route wires away from moving parts or sharp edges.

- Use wire loom for extra protection if needed.

Reinstall the Instrument Cluster

- Gently push the cluster back into place.

- Secure it with screws or clips.

- Reattach the dashboard trim.

Troubleshooting Common Issues

Even with careful work, problems can arise. Here’s how to fix the most common ones.

LED Doesn’t Light Up

- Check polarity—reverse the connections if needed.

- Test the circuit with a multimeter to ensure power is reaching the LED.

- Verify the LED isn’t defective by testing it with a 9V battery.

Dashboard Shows “Bulb Out” Warning

- This happens because LEDs draw less current than incandescent bulbs.

- Solution: Install a load resistor or use a CAN bus-compatible LED designed to mimic the original bulb’s resistance.

LED Flickers or Fades

- Likely caused by a poor solder joint or loose connection.

- Re-solder the connection and ensure heat shrink is properly sealed.

Battery Drains Quickly

- LEDs use very little power, so this is unlikely—unless there’s a short circuit.

- Check for exposed wires touching metal or each other.

Final Tips for Success

- Work in a clean, well-lit area: This reduces mistakes and makes it easier to see small wires.

- Take photos before disconnecting: Snap pictures of the wiring setup so you can reference them later.

- Use automotive-grade components: Regular electronics may not withstand heat, vibration, or moisture in a car.

- Don’t rush: Electrical work requires patience—rushing leads to errors.

Conclusion

Connecting LED wires to an LED engine light is a rewarding DIY project that enhances your vehicle’s functionality and appearance. By following this guide, you’ve learned how to safely disconnect the battery, identify wiring polarity, solder connections, and troubleshoot common issues. With the right tools and careful attention to detail, you can achieve a professional-quality installation that lasts for years.

Remember: always prioritize safety, double-check your work, and test before finalizing. Whether you’re upgrading for brightness, efficiency, or style, your new LED engine light will serve you well—just make sure it’s wired correctly from the start.