Discover how to diagnose the check engine light on your 1996 Ford F150 using basic tools and the truck’s onboard diagnostic system. This guide walks you through reading trouble codes manually, understanding common issues, and deciding when to seek professional help—perfect for DIYers in 2026.

Key Takeaways

- Manual Code Reading: The 1996 Ford F150 uses OBD-I, allowing you to read diagnostic trouble codes (DTCs) without a scanner by jumping the diagnostic connector.

- Common Causes: Frequent triggers include faulty oxygen sensors, loose gas caps, vacuum leaks, and ignition system problems.

- Tools Needed: All you need is a paperclip or jumper wire and a pen to record flashing light patterns.

- Code Interpretation: Learn how to decode two-digit trouble codes from the flashing check engine light sequence.

- Preventive Maintenance: Regular inspections of spark plugs, air filters, and fuel systems can prevent future light activations.

- When to Call a Mechanic: If the light flashes repeatedly or returns after clearing, professional diagnostics may be necessary.

- 2026 Relevance: Even with modern tech, older trucks like the ’96 F150 remain reliable—this guide ensures you can maintain them effectively.

How to Check Check Engine Light 96 Ford F150: A Complete DIY Guide for 2026

If you’re driving a 1996 Ford F150 in 2026, you’re likely proud of its durability and classic design. But when that dreaded check engine light pops up on the dashboard, it can cause instant anxiety. Don’t worry—this guide will walk you through exactly how to check the check engine light on your 96 Ford F150 using simple, low-cost methods. Whether you’re a seasoned DIYer or just starting out, you’ll learn how to read diagnostic trouble codes (DTCs), understand what they mean, and take the right next steps—all without spending money at the repair shop.

The 1996 Ford F150 uses an OBD-I (On-Board Diagnostics, Generation 1) system, which predates the more advanced OBD-II standard introduced in 1996 for most vehicles. This means you can’t plug in a modern OBD-II scanner and expect it to work. Instead, Ford designed a clever manual method to retrieve trouble codes using the truck’s own dashboard lights. It’s a bit old-school, but it’s reliable and doesn’t require expensive tools.

In this guide, we’ll cover everything from locating the diagnostic port to interpreting flashing light patterns. We’ll also go over common causes of the check engine light, troubleshooting tips, and when it’s time to call in a professional. By the end, you’ll feel confident diagnosing issues with your F150 and keeping it running smoothly for years to come.

Understanding the 1996 Ford F150’s OBD-I System

Visual guide about How to Check Check Engine Light 96 Ford F150

Image source: vehiclechef.com

Before jumping into the steps, it’s important to understand how the 1996 Ford F150’s diagnostic system works. Unlike newer trucks with OBD-II ports that connect to scanners, the ’96 F150 uses a self-diagnostic mode that communicates through the check engine light (also called the “MIL” or Malfunction Indicator Lamp).

The OBD-I system monitors key engine functions like fuel delivery, ignition timing, and emissions. When a sensor detects an anomaly—such as a misfire, low oxygen levels, or a vacuum leak—the engine control module (ECM) stores a trouble code and triggers the check engine light.

The beauty of this system is its simplicity. You don’t need a computer or smartphone app. All you need is a paperclip and a few minutes of your time. The ECM will “talk” to you by flashing the check engine light in a specific pattern that corresponds to a two-digit code. Once you decode it, you can look up the issue and decide how to fix it.

Tools and Safety Precautions

You don’t need much to check the check engine light on your 1996 Ford F150. Here’s what you’ll need:

- Paperclip or Jumper Wire: A standard metal paperclip works perfectly. Straighten it out so you can insert it into the diagnostic connector.

- Pen and Paper: To record the flashing light sequence and write down the trouble code.

- Flashlight (Optional): If you’re working in low light, a flashlight helps you see the diagnostic port clearly.

- Gloves and Safety Glasses (Recommended): While this process is low-risk, it’s always smart to protect yourself.

Safety First

Before you begin, make sure your truck is parked on a flat surface, the engine is off, and the keys are removed from the ignition. Never attempt this procedure while the engine is running. Also, avoid touching any moving parts under the hood, such as the fan or belts.

Step-by-Step: How to Read Check Engine Light Codes on a 1996 Ford F150

Now that you’re prepared, let’s get into the actual process. Follow these steps carefully to retrieve the trouble codes from your truck’s ECM.

Step 1: Locate the Diagnostic Connector

The first step is finding the diagnostic connector, also known as the “Self-Test Input” (STI) connector. On the 1996 Ford F150, it’s located under the hood on the driver’s side, near the firewall. It’s a small, rectangular plug with two wires—usually yellow and green—coming out of it.

Look for a black or gray plastic connector with two pins. It’s often tucked behind the brake fluid reservoir or near the master cylinder. If you’re having trouble finding it, consult your owner’s manual or look for a label that says “DIAGNOSTIC” or “SELF TEST.”

Step 2: Prepare the Jumper Wire

Take your paperclip or jumper wire and straighten it out. You’ll use this to “jump” the two pins in the diagnostic connector, which tells the ECM to enter diagnostic mode.

Make sure the wire is clean and free of insulation. You want a solid metal connection between the two pins.

Step 3: Insert the Jumper Wire

With the ignition off, carefully insert one end of the paperclip into each of the two pins in the diagnostic connector. You should feel a slight resistance—don’t force it. The goal is to create a temporary bridge between the two circuits.

Once the wire is in place, you’re ready to turn on the ignition.

Step 4: Turn the Ignition to “On” (Do Not Start the Engine)

Turn the key to the “ON” position. The dashboard lights should illuminate, including the check engine light. Do not start the engine—just leave it in the “ON” position.

At this point, the ECM will detect the jumper wire and begin transmitting trouble codes through the check engine light.

Step 5: Observe the Flashing Pattern

Watch the check engine light closely. It will begin to flash in a series of short and long pulses. These flashes represent numbers.

– A short flash = 1

– A long flash = 5

The flashes are grouped into two-digit codes. For example:

– One long flash (5) followed by three short flashes (3) = Code 53

– Two short flashes (2) followed by four short flashes (4) = Code 24

There will be a brief pause between digits and a longer pause between codes if multiple codes are stored.

Step 6: Record the Code(s)

Use your pen and paper to write down each code as it appears. For example, if you see: long flash, short flash, short flash, short flash, pause, long flash, long flash, pause—that’s Code 53, then Code 55.

Some trucks may display multiple codes. Record them all in the order they appear.

Step 7: Turn Off the Ignition and Remove the Jumper

Once the codes have finished displaying (usually after 2–3 repetitions), turn the ignition back to “OFF” and carefully remove the paperclip from the diagnostic connector.

You’ve now successfully retrieved the trouble codes from your 1996 Ford F150.

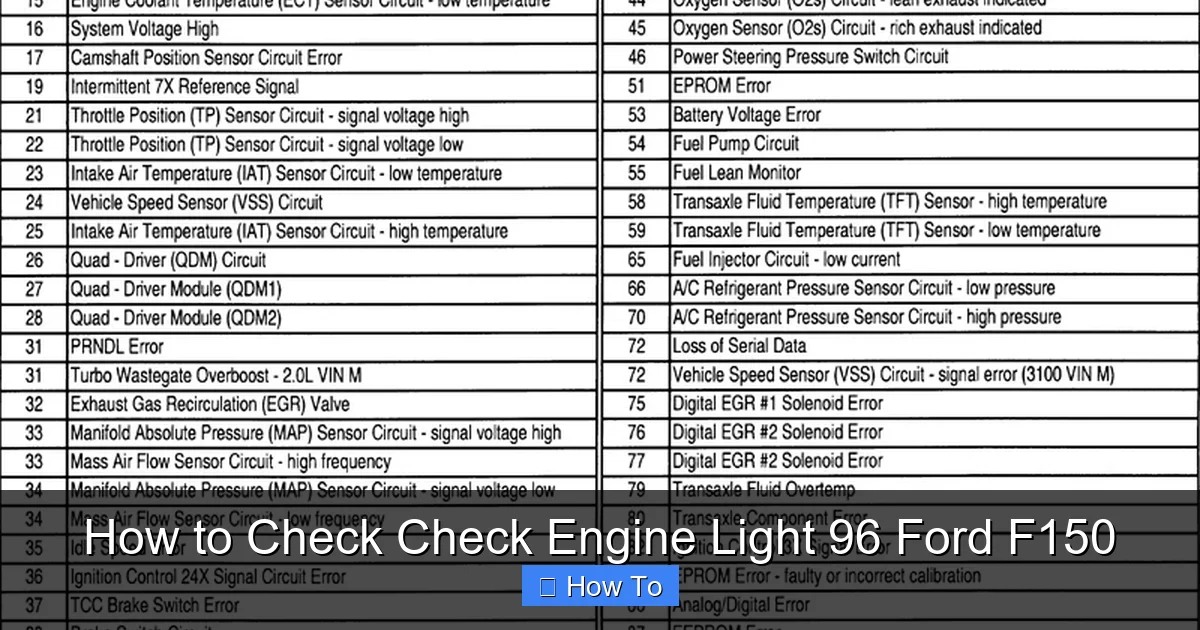

How to Interpret the Trouble Codes

Now that you have the code(s), it’s time to figure out what they mean. The 1996 Ford F150 uses a standardized set of OBD-I codes, but they’re not the same as modern OBD-II codes. Here are some of the most common ones:

- Code 11: Oxygen sensor circuit malfunction (often a faulty O2 sensor)

- Code 12: No airflow detected (could indicate a problem with the mass airflow sensor or vacuum leak)

- Code 13: Oxygen sensor not switching (sensor stuck rich or lean)

- Code 14: Coolant temperature sensor out of range

- Code 15: Transmission fluid temperature sensor issue

- Code 17: Engine coolant temperature below thermostat regulating temperature

- Code 21: Throttle position sensor (TPS) out of range

- Code 22: MAP sensor (Manifold Absolute Pressure) signal out of range

- Code 24: Intake air temperature sensor malfunction

- Code 32: EGR system malfunction (Exhaust Gas Recirculation)

- Code 41: Oxygen sensor indicates lean condition (Bank 1)

- Code 51: System too lean (fuel mixture issue)

- Code 52: System too rich

- Code 53: Oxygen sensor signal stuck rich

- Code 54: Oxygen sensor signal stuck lean

- Code 55: Oxygen sensor heater circuit malfunction

- Code 61: Oxygen sensor indicates rich condition (Bank 1)

- Code 79: A/C clutch circuit malfunction

You can find full code lists online or in repair manuals specific to the 1996 Ford F150. Websites like Ford-Trucks.com or forums dedicated to older F-Series trucks often have detailed breakdowns.

Common Causes of the Check Engine Light in a 1996 Ford F150

Now that you know how to read the codes, let’s look at some of the most frequent reasons the check engine light comes on in this model.

1. Faulty Oxygen (O2) Sensor

The O2 sensor monitors the amount of oxygen in the exhaust gases. If it fails, the engine may run too rich (too much fuel) or too lean (too little fuel), reducing fuel efficiency and increasing emissions. Codes like 11, 13, 41, 53, and 61 often point to O2 sensor issues.

2. Loose or Damaged Gas Cap

A loose, cracked, or missing gas cap can cause fuel vapors to escape, triggering a small leak in the evaporative emissions system. This is one of the easiest fixes—simply tighten or replace the cap and see if the light goes off after a few drive cycles.

3. Vacuum Leaks

Vacuum leaks occur when air enters the engine through cracked hoses, gaskets, or intake manifold seals. This disrupts the air-fuel ratio and can trigger codes like 12, 22, or 51. Listen for a hissing sound under the hood when the engine is running.

4. Ignition System Problems

Worn spark plugs, bad ignition coils, or faulty wires can cause misfires. While the ’96 F150 doesn’t have a direct misfire code like OBD-II systems, symptoms like rough idle, hesitation, or poor acceleration often accompany ignition issues.

5. Mass Airflow (MAF) Sensor Issues

The MAF sensor measures how much air is entering the engine. If it’s dirty or malfunctioning, the ECM can’t calculate the correct fuel mixture. Cleaning the MAF sensor with specialized spray can sometimes resolve the issue.

6. EGR Valve Malfunction

The Exhaust Gas Recirculation (EGR) valve reduces nitrogen oxide emissions by recirculating a portion of exhaust gas back into the combustion chamber. If it gets stuck open or closed, it can cause rough idle, stalling, or poor performance—often triggering Code 32.

7. Coolant Temperature Sensor Failure

This sensor tells the ECM how hot the engine is. If it sends incorrect data, the engine may run too rich or too lean, especially when cold. Code 14 is a common indicator.

Troubleshooting and Next Steps

Once you’ve identified the code and possible cause, it’s time to take action. Here’s how to proceed based on the issue.

If the Code Points to a Simple Fix

Some problems are easy to resolve:

– Gas cap: Tighten or replace it. Drive the truck for 50–100 miles and see if the light turns off.

– Dirty MAF sensor: Remove it and clean it with MAF cleaner spray. Avoid touching the delicate wire inside.

– Loose vacuum hose: Inspect all hoses under the hood. Replace any that are cracked or brittle.

If the Code Indicates a Sensor Failure

Sensors like the O2 sensor, TPS, or coolant temperature sensor may need replacement. These parts are relatively affordable and can often be installed with basic tools. Always disconnect the battery before replacing electrical components.

If You’re Unsure or the Light Returns

If the check engine light comes back after clearing the code, or if you’re not comfortable performing repairs, it’s time to visit a trusted mechanic. Modern diagnostic tools can still read OBD-I systems, and a professional can perform a deeper inspection.

How to Clear the Check Engine Light

After fixing the issue, you’ll want to clear the code so the light turns off. On the 1996 F150, you can do this by:

1. Disconnecting the negative battery cable for 10–15 minutes.

2. Reconnecting the cable and starting the truck.

Note: This will also reset the radio presets and clock, so be prepared to reprogram them.

Alternatively, some auto parts stores offer free code clearing services—just ask when you visit.

Preventive Maintenance Tips for 2026 Owners

Even in 2026, the 1996 Ford F150 remains a reliable workhorse—if properly maintained. Here are some tips to prevent future check engine light issues:

- Replace spark plugs and wires every 30,000–50,000 miles. Use high-quality parts designed for your engine.

- Inspect vacuum hoses annually. Look for cracks, brittleness, or loose connections.

- Use a fuel system cleaner every 10,000 miles. This helps keep injectors and sensors clean.

- Check the gas cap regularly. Make sure it seals properly after every fill-up.

- Monitor engine performance. If you notice rough idle, hesitation, or poor fuel economy, address it early.

- Keep up with coolant and oil changes. Clean fluids help sensors and the ECM function properly.

When to Seek Professional Help

While many check engine light issues on the 1996 F150 can be DIY fixes, some situations require expert attention:

– The light flashes continuously (indicating a severe misfire that can damage the catalytic converter).

– Multiple codes appear, suggesting a complex electrical or mechanical problem.

– You’ve replaced a part, but the light returns.

– You’re unsure how to safely perform the repair.

Modern mechanics are still trained to work on older vehicles, and many shops offer affordable diagnostics. Don’t hesitate to get a second opinion if something feels off.

Conclusion

Checking the check engine light on your 1996 Ford F150 doesn’t have to be intimidating. With just a paperclip and a few minutes, you can read trouble codes, understand what’s wrong, and take action—whether that’s tightening a gas cap or replacing a sensor. This classic truck may be over 30 years old, but with proper care, it can still deliver reliable performance in 2026 and beyond.

By following this guide, you’ve gained the knowledge to diagnose issues confidently, save money on diagnostics, and keep your F150 running strong. Remember: the check engine light is your truck’s way of asking for help. Listen to it, respond promptly, and you’ll enjoy many more miles on the road.