This guide walks you through how to check the check engine light on a 1995 Ford F150 using basic tools and the truck’s onboard diagnostic system. You’ll learn to read trouble codes without a scanner and understand what they mean.

Key Takeaways

- Manual Code Reading: The 1995 Ford F150 uses OBD-I, allowing you to read diagnostic trouble codes (DTCs) without a modern scanner by jumping two pins in the diagnostic connector.

- Simple Tools Required: All you need is a paperclip, flashlight, and notepad—no expensive equipment necessary.

- Understanding Flash Patterns: The check engine light flashes in sequences that correspond to specific trouble codes—learning to count these flashes is key.

- Common Issues Identified: Frequent problems include faulty oxygen sensors, vacuum leaks, ignition coil issues, and EGR valve malfunctions.

- Resetting the Light: After repairs, you can reset the check engine light by disconnecting the battery or clearing codes via the diagnostic port.

- When to Seek Help: If codes point to complex electrical or engine issues, consult a professional mechanic to avoid further damage.

- Preventive Maintenance: Regular tune-ups and sensor checks can prevent future check engine light activations.

How to Check Check Engine Light 95 Ford F150: A Complete 2026 Guide

If you’re driving a classic 1995 Ford F150 and the check engine light suddenly comes on, don’t panic—this guide will show you exactly how to check the check engine light on a 1995 Ford F150 using simple, proven methods. Unlike modern vehicles with advanced OBD-II systems, the 1995 F150 uses an older OBD-I (On-Board Diagnostics, Generation I) system. While it lacks the plug-and-play convenience of today’s scanners, it still provides valuable diagnostic information—if you know how to read it.

In this comprehensive guide, updated for 2026, we’ll walk you through every step of diagnosing your truck’s check engine light. You’ll learn how to retrieve trouble codes manually, interpret flash patterns, understand what those codes mean, and take appropriate action. Whether you’re a seasoned DIYer or a first-time Ford owner, this guide is designed to be easy to follow, practical, and packed with real-world tips.

By the end of this article, you’ll be able to confidently troubleshoot your F150’s engine issues, save money on diagnostic fees, and keep your truck running smoothly for years to come.

Why the Check Engine Light Comes On

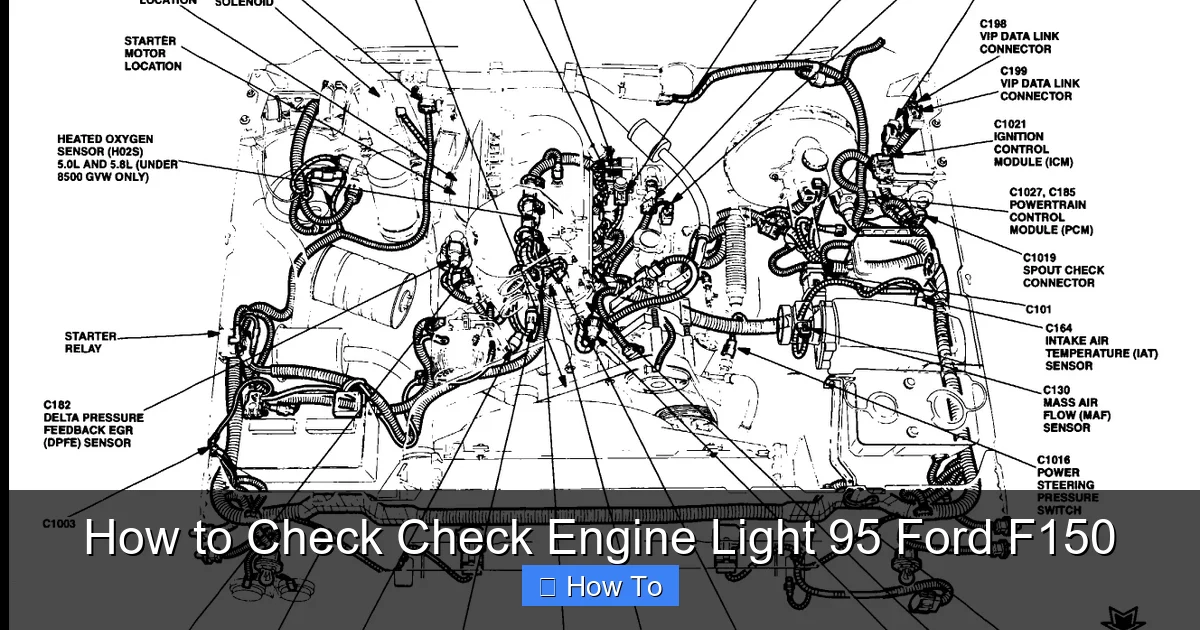

Visual guide about How to Check Check Engine Light 95 Ford F150

Image source: justanswer.com

Before diving into the how-to, it’s important to understand why the check engine light might illuminate in your 1995 Ford F150. The light—often labeled “Check Engine” or “Service Engine Soon”—is part of the truck’s onboard diagnostic system. When the engine control module (ECM) detects a problem that could affect emissions or engine performance, it triggers the light and stores a diagnostic trouble code (DTC).

Common reasons for the light to come on include:

- Faulty oxygen (O2) sensors: These monitor exhaust gases and help regulate the air-fuel mixture. A failing sensor can reduce fuel efficiency and increase emissions.

- Vacuum leaks: Cracked hoses or loose connections allow unmetered air into the engine, causing rough idling and poor performance.

- Ignition system problems: Worn spark plugs, bad ignition coils, or damaged wires can cause misfires.

- EGR valve malfunction: The Exhaust Gas Recirculation valve reduces nitrogen oxide emissions. If it sticks open or closed, it can trigger the light.

- Mass Air Flow (MAF) sensor issues: This sensor measures incoming air. Dirt or damage can lead to incorrect fuel delivery.

- Loose or damaged gas cap: Believe it or not, a loose cap can cause a pressure leak in the fuel system, triggering the light.

Understanding these common causes helps you interpret the codes you retrieve and prioritize repairs.

Tools You’ll Need

One of the best things about diagnosing a 1995 Ford F150 is that you don’t need expensive tools. Here’s what you’ll need:

- A paperclip or small jumper wire: This is used to bridge two terminals in the diagnostic connector.

- A flashlight: Helps you see the diagnostic port, especially in low-light conditions.

- A notepad and pen: To record the trouble codes as they flash.

- Basic hand tools (optional): Screwdrivers or wrenches may be needed to access certain components during repairs.

That’s it! No OBD-II scanner required. The 1995 F150’s OBD-I system was designed to be accessible to everyday drivers, and Ford made it possible to read codes manually.

Locating the Diagnostic Connector

The first step in checking the check engine light is finding the diagnostic connector. In the 1995 Ford F150, this port is typically located under the hood, near the driver’s side firewall.

Step-by-Step Location Guide

- Open the hood and look along the driver’s side inner fender wall.

- The diagnostic connector is a small, rectangular plastic box, usually black or gray.

- It has 6 pins arranged in two rows of three.

- It’s often labeled “DLC” (Data Link Connector) or “Self-Test Connector.”

- If you can’t find it, check near the brake master cylinder or behind the battery—some models vary slightly.

Once you’ve located the connector, you’re ready to begin the code retrieval process.

How to Retrieve Trouble Codes Manually

Now comes the core of the process: retrieving the diagnostic trouble codes using the truck’s built-in self-test feature. This method uses the check engine light to flash codes in a specific pattern.

Step 1: Prepare the Vehicle

Before starting, make sure:

- The ignition is turned off.

- The engine is cool (to avoid burns).

- The battery is fully charged (a weak battery can cause false readings).

- All accessories (lights, radio, A/C) are turned off.

Step 2: Jump the Diagnostic Connector

This is the key step. You’ll use a paperclip or jumper wire to connect two specific pins in the DLC.

- Straighten a paperclip or use a short piece of insulated wire.

- Locate pins “A” and “B” in the 6-pin connector. These are usually the two pins on the bottom row, farthest to the left and right.

- Insert one end of the paperclip into pin A and the other into pin B. This creates a short circuit that tells the ECM to enter self-test mode.

Important: Do not turn the ignition on yet. The jumper should be in place before powering up.

Step 3: Turn the Ignition to “On” (Do Not Start the Engine)

With the paperclip still in place:

- Turn the key to the “ON” position (dashboard lights should illuminate).

- Do not start the engine—just leave it in the “ON” state.

- Watch the check engine light on the dashboard.

Within a few seconds, the light will begin to flash. These flashes represent the trouble codes.

Step 4: Read the Flash Patterns

The check engine light will flash in a series of long and short pulses. Each code is represented by two numbers:

- Long flashes = tens digit

- Short flashes = ones digit

For example:

- If the light flashes 3 times, pauses, then flashes 2 times, the code is 32.

- If it flashes 1 time, pauses, then 5 times, the code is 15.

The system will repeat the code sequence several times. Write down each code as it appears.

Step 5: Record All Codes

Some issues may trigger multiple codes. The ECM will cycle through all stored codes, so pay close attention. Common sequences include:

- Code 12: Normal operation (no faults detected at startup)

- Code 13: Oxygen sensor circuit malfunction

- Code 14: Throttle Position Sensor (TPS) issue

- Code 15: Engine Coolant Temperature (ECT) sensor problem

- Code 17: Vehicle Speed Sensor (VSS) fault

After recording all codes, remove the paperclip and turn the ignition off.

Understanding the Trouble Codes

Once you’ve retrieved the codes, the next step is understanding what they mean. The 1995 Ford F150 uses a standardized set of OBD-I codes, but they’re not the same as modern OBD-II codes. Here’s a breakdown of common codes and their meanings:

Common OBD-I Codes for 1995 Ford F150

- Code 11: System pass (no fault detected)

- Code 12: No RPM signal during cranking (common during self-test)

- Code 13: Oxygen sensor circuit open or shorted

- Code 14: Throttle Position Sensor (TPS) out of range

- Code 15: Engine Coolant Temperature (ECT) sensor high input

- Code 17: Vehicle Speed Sensor (VSS) signal missing

- Code 21: ECT sensor low input (engine running cold)

- Code 22: Manifold Absolute Pressure (MAP) sensor high input

- Code 23: MAP sensor low input

- Code 32: EGR valve not opening (stuck closed)

- Code 33: EGR valve stuck open or flow insufficient

- Code 41: Oxygen sensor indicates lean condition (front sensor)

- Code 42: Oxygen sensor indicates rich condition (front sensor)

- Code 51: System pass (used in some models)

- Code 52: Transmission torque converter clutch not engaging

- Code 53: Overdrive cancel switch circuit fault

- Code 54: Transmission fluid temperature sensor high

- Code 61: Oxygen sensor indicates lean (rear sensor, if equipped)

- Code 62: Oxygen sensor indicates rich (rear sensor)

- Code 71: Transmission shift solenoid A malfunction

- Code 72: Transmission shift solenoid B malfunction

- Code 73: Transmission pressure control solenoid fault

- Code 74: Transmission 3-4 shift solenoid fault

- Code 75: Transmission 2-3 shift solenoid fault

Note: Some codes may vary slightly depending on engine type (4.9L inline-6, 5.0L V8, or 5.8L V8) and transmission (manual or automatic). Always cross-reference with a Ford-specific OBD-I code chart if possible.

What to Do After Reading the Codes

Once you’ve identified the trouble codes, it’s time to take action. Here’s how to proceed based on the code type:

For Sensor-Related Codes (e.g., O2, TPS, ECT)

- Inspect the sensor and its wiring for damage, corrosion, or loose connections.

- Clean the sensor if it’s dirty (e.g., MAF sensor).

- Replace the sensor if it’s faulty. Most sensors are relatively inexpensive and easy to replace.

- After replacement, clear the codes and test drive the truck.

For EGR Valve Codes (e.g., 32, 33)

- Remove the EGR valve and inspect for carbon buildup.

- Clean it with carburetor cleaner and a soft brush.

- If it’s stuck or damaged, replace it.

- Check the vacuum lines connected to the EGR valve for cracks or leaks.

For Ignition System Codes (e.g., misfires)

- Check spark plugs, wires, and ignition coils.

- Replace worn components.

- Ensure proper gap on spark plugs.

For Vacuum Leaks

- Inspect all vacuum hoses for cracks, brittleness, or disconnections.

- Use a smoke machine or carb cleaner spray to locate leaks (listen for engine RPM changes).

- Replace damaged hoses.

How to Clear the Check Engine Light

After making repairs, you’ll want to clear the trouble codes and turn off the check engine light. Here are two methods:

Method 1: Disconnect the Battery

- Turn off the ignition and remove the key.

- Disconnect the negative (-) battery cable using a wrench.

- Wait at least 10–15 minutes to allow the ECM to reset.

- Reconnect the battery cable.

- Start the engine and check if the light remains off.

Note: This method resets all ECM memory, including radio presets and learned driving patterns. The light may come back on if the issue isn’t fully resolved.

Method 2: Use the Diagnostic Connector (Advanced)

Some Ford OBD-I systems allow you to clear codes by cycling the ignition with the jumper in place:

- Reinsert the paperclip into pins A and B.

- Turn the ignition to “ON” for 10 seconds.

- Turn it off and remove the paperclip.

- Start the engine and check the light.

This method may not work on all 1995 F150s, so battery disconnection is more reliable.

Troubleshooting Tips and Common Mistakes

Even with the right steps, things can go wrong. Here are some tips to avoid common pitfalls:

- Don’t start the engine while the jumper is in place: This can damage the ECM or cause false readings.

- Ensure the paperclip makes solid contact: Loose connections can prevent the system from entering self-test mode.

- Double-check pin locations: Misidentifying pins A and B is a common error. Refer to a diagram if unsure.

- Wait for the full code sequence: The ECM may take 10–20 seconds to begin flashing. Be patient.

- Don’t ignore intermittent codes: Even if the light goes off, stored codes can indicate underlying issues.

- Use a code reference chart: Print or bookmark a 1995 Ford F150 OBD-I code list for quick reference.

When to Call a Professional

While many check engine light issues can be resolved at home, some problems require professional attention. Consider visiting a mechanic if:

- The codes point to internal engine damage (e.g., low compression, timing issues).

- You’re unsure how to safely replace a component.

- The light returns immediately after clearing codes.

- You suspect electrical problems beyond your skill level.

- The truck is running poorly, overheating, or emitting smoke.

A certified Ford technician can perform advanced diagnostics and ensure repairs are done correctly.

Preventive Maintenance to Avoid Future Issues

The best way to deal with the check engine light is to prevent it from coming on in the first place. Follow these maintenance tips:

- Replace spark plugs and wires every 30,000–50,000 miles.

- Inspect and clean the MAF sensor annually.

- Check and replace the air filter regularly.

- Use high-quality fuel and consider fuel system cleaners.

- Inspect vacuum hoses during oil changes.

- Test the battery and alternator every 2–3 years.

- Keep the gas cap tight and replace it if cracked.

Regular care keeps your 1995 F150 running strong and reduces the chances of unexpected check engine light surprises.

Conclusion

Checking the check engine light on a 1995 Ford F150 doesn’t require a mechanic or expensive tools. With just a paperclip and a few minutes of your time, you can retrieve diagnostic trouble codes, understand what they mean, and take steps to fix the problem. This guide has walked you through every stage—from locating the diagnostic connector to interpreting flash patterns and clearing codes.

Remember, the key to success is patience and attention to detail. Don’t rush the process, and always double-check your work. By learning how to check the check engine light on a 1995 Ford F150, you’re not only saving money on diagnostics—you’re also gaining valuable knowledge about your truck’s health.

Whether you’re restoring a classic F150 or just keeping your daily driver in top shape, this skill will serve you well for years to come. Stay proactive, stay informed, and keep that check engine light in check.