Discover how to diagnose your 1994 Toyota Pickup’s check engine light using simple tools and techniques. This guide walks you through manual code reading, common causes, and next steps—perfect for DIYers in 2026.

Key Takeaways

- Manual code retrieval is possible: The 1994 Toyota Pickup uses OBD-I, so you can read trouble codes without a scanner by shorting two terminals in the diagnostic port.

- Check engine light indicates a problem: Ignoring the light can lead to reduced fuel efficiency, engine damage, or failed emissions tests.

- Common causes include faulty sensors: Oxygen sensors, EGR valves, and vacuum leaks are frequent culprits in older Toyotas.

- Use a multimeter for deeper diagnosis: Once you have the code, test components like the coolant temperature sensor or ignition coil to confirm the issue.

- Clear codes manually after repairs: After fixing the problem, disconnect the battery for 10–15 minutes to reset the ECU and turn off the light.

- Keep a repair log: Documenting codes and fixes helps track recurring issues and improves long-term maintenance.

- Consider upgrading to OBD-II tools: While your truck is OBD-I, using an OBD-I to OBD-II adapter with modern software can simplify diagnostics in 2026.

How to Check My 94 Toyota Pickup Check Engine Light

If you’re driving a classic 1994 Toyota Pickup in 2026, you’re likely proud of its reliability and longevity. But when that dreaded check engine light flickers on, it can cause instant stress—especially if you’re not familiar with older vehicle diagnostics. The good news? Your 94 Toyota Pickup uses an OBD-I (On-Board Diagnostics I) system, which means you can read trouble codes manually without expensive tools. This guide will walk you through every step of checking, interpreting, and responding to your check engine light—so you can keep your truck running smoothly for years to come.

Whether you’re a seasoned DIY mechanic or a first-time troubleshooter, this comprehensive how-to guide will empower you to take control of your vehicle’s health. We’ll cover everything from locating the diagnostic port to understanding what each code means, plus practical tips for fixing common issues. By the end, you’ll know exactly how to check your 94 Toyota Pickup check engine light and what to do next.

Understanding the 1994 Toyota Pickup’s OBD-I System

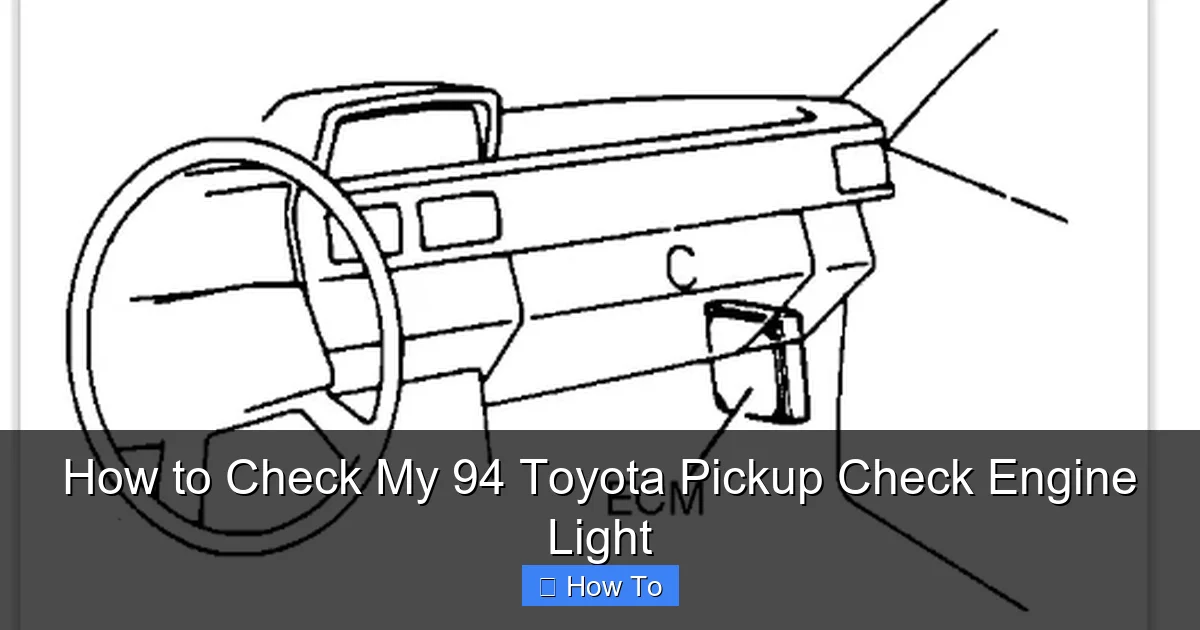

Visual guide about How to Check My 94 Toyota Pickup Check Engine Light

Image source: static.foxdealer.com

Before diving into the steps, it’s important to understand how your truck’s diagnostic system works. Unlike modern vehicles with OBD-II (which became standard in 1996), the 1994 Toyota Pickup uses the older OBD-I system. This means it doesn’t support universal scan tools, but it does allow for manual code retrieval using a simple jumper wire or paperclip.

The OBD-I system monitors key engine functions such as ignition timing, fuel delivery, and emissions. When a sensor detects an anomaly—like a misfire, low oxygen levels, or a faulty component—the Engine Control Unit (ECU) stores a trouble code and illuminates the check engine light. These codes are two-digit numbers that correspond to specific issues.

One advantage of OBD-I is its simplicity. You don’t need a $200 scanner or smartphone app. All you need is access to the diagnostic port under the hood and a basic understanding of how to read flashing lights. This makes diagnosing your 94 Toyota Pickup accessible even in 2026, when newer tech dominates the market.

Tools and Materials You’ll Need

Before starting, gather these items to make the process smooth and safe:

- A small jumper wire (or a straightened paperclip)

- A flashlight (for better visibility under the hood)

- A notebook and pen (to record trouble codes)

- A multimeter (optional, for advanced testing)

- Basic hand tools (screwdrivers, wrenches) if repairs are needed

- Owner’s manual (for reference, if available)

You don’t need anything fancy—just a few simple tools that most people already have at home. If you’re planning to do deeper diagnostics, a multimeter is highly recommended. It allows you to test sensors, check voltage, and verify electrical connections.

Step 1: Locate the Diagnostic Port

The first step in checking your 94 Toyota Pickup check engine light is finding the diagnostic port. Unlike modern vehicles with a standardized OBD-II port under the dashboard, the OBD-I system in your truck uses a unique connector located under the hood.

Where to Find It

Open the hood and look near the driver’s side firewall—the large metal wall separating the engine compartment from the cabin. You’re looking for a small, rectangular connector with multiple pins. It’s usually labeled “DIAGNOSTIC” or “DLC” (Data Link Connector). On most 1994 Toyota Pickups, it’s a 6-pin connector mounted on a bracket near the brake master cylinder.

If you can’t find it, consult your owner’s manual or look for a small plastic cover labeled “DIAG.” Some models have it tucked behind a rubber grommet or near the ECU (Engine Control Unit), which is typically mounted on the driver’s side inner fender.

Identifying the Correct Pins

The diagnostic port has six pins, but you only need to focus on two: **TE1** (Test Engine 1) and **E1** (Engine Ground). These are usually the two center pins. TE1 is used to trigger the code readout, while E1 provides the ground connection.

To confirm, look for markings on the connector or nearby. If there are no labels, refer to a wiring diagram for your specific model. You can find these online through Toyota forums or repair manuals. In a pinch, the TE1 pin is often the one closest to the ECU harness.

Step 2: Prepare the Vehicle for Diagnosis

Before retrieving codes, make sure your truck is ready for testing. This ensures accurate results and prevents damage.

Turn Off the Engine

Make sure the engine is completely off and the key is removed from the ignition. This prevents accidental starts and protects the ECU during the procedure.

Ensure the Battery is Connected

The ECU needs power to communicate. Check that the battery terminals are clean and tight. A weak or disconnected battery can cause false readings or prevent the system from responding.

Set the Parking Brake and Chock the Wheels

For safety, engage the parking brake and place wheel chocks behind the rear tires. Even though the engine won’t start, it’s good practice to secure the vehicle.

Step 3: Retrieve the Trouble Codes

Now it’s time to read the codes. This is the core of how to check your 94 Toyota Pickup check engine light.

Insert the Jumper Wire

Take your jumper wire or straightened paperclip and insert one end into the **TE1** pin and the other into the **E1** pin. Make sure the connection is secure—loose contact can cause intermittent signals.

Turn the Ignition to “ON”

With the jumper in place, turn the key to the “ON” position (but do not start the engine). The dashboard lights should illuminate, including the check engine light.

Watch the Check Engine Light

The check engine light will begin to flash in a specific pattern. Each flash represents a digit in the trouble code. For example:

– A long flash = 10

– A short flash = 1

So, two long flashes followed by three short flashes would be code **23**.

Record the Code Sequence

Write down each code as it appears. The system will repeat the sequence after a short pause. If multiple codes are stored, they will be displayed in numerical order.

For example:

– Code 21: Oxygen sensor malfunction

– Code 22: Coolant temperature sensor issue

– Code 25: Air/fuel ratio imbalance

Some codes may appear as “12” or “41,” which are common in older Toyotas. Refer to a Toyota OBD-I code chart (available online) to interpret them.

Remove the Jumper and Turn Off the Ignition

Once you’ve recorded all codes, remove the jumper wire and turn the key back to “OFF.” This completes the diagnostic cycle.

Step 4: Interpret the Trouble Codes

Now that you have the codes, it’s time to understand what they mean. Here are some of the most common trouble codes for the 1994 Toyota Pickup:

- Code 12: RPM signal not detected – Check crankshaft position sensor or wiring.

- Code 13: RPM signal abnormal – Could indicate a faulty distributor or timing issue.

- Code 14: Ignition signal missing – Often caused by a bad ignition coil or ECM.

- Code 21: Oxygen sensor (O2) malfunction – Common in high-mileage trucks; sensor may need replacement.

- Code 22: Coolant temperature sensor (ECT) out of range – Check sensor resistance with a multimeter.

- Code 25: Air/fuel ratio too rich or lean – Could be due to vacuum leaks, dirty injectors, or faulty MAF sensor.

- Code 31: Air pump system malfunction – Related to emissions; check air injection valve.

- Code 41: Air/fuel ratio sensor (A/F) circuit issue – Similar to Code 21 but for the front O2 sensor.

Use a reliable OBD-I code reference for Toyota vehicles to get accurate interpretations. Websites like ToyotaNation.com or forums dedicated to vintage Toyotas often have detailed breakdowns.

Step 5: Diagnose the Root Cause

Once you know the code, it’s time to investigate the underlying problem. Here’s how to approach common issues:

Oxygen Sensor (Code 21 or 41)

The O2 sensor monitors exhaust gases and helps the ECU adjust the air/fuel mixture. Over time, it can become contaminated or fail.

– **Test it:** Use a multimeter to check resistance. A healthy O2 sensor should show changing voltage (0.1–0.9V) when the engine is warm.

– **Fix it:** Replace the sensor if readings are static or out of range. Use a Toyota-specific O2 sensor for best results.

Coolant Temperature Sensor (Code 22)

This sensor tells the ECU how hot the engine is. A faulty reading can cause poor fuel economy or hard starts.

– **Test it:** Disconnect the sensor and measure resistance with a multimeter. Compare to specifications (e.g., ~2,000 ohms at 68°F).

– **Fix it:** Replace if resistance is out of range or the sensor is cracked.

Vacuum Leaks (Code 25)

A vacuum leak allows unmetered air into the engine, causing a lean condition.

– **Inspect hoses:** Look for cracked, loose, or disconnected vacuum lines, especially around the intake manifold and PCV valve.

– **Use carb cleaner:** Spray around suspected areas while the engine runs. If RPM increases, you’ve found a leak.

Ignition System (Code 14)

A weak ignition signal can prevent the engine from starting or cause misfires.

– **Check the coil:** Test primary and secondary resistance with a multimeter.

– **Inspect distributor:** Look for worn cap, rotor, or carbon tracking.

Step 6: Perform Repairs and Clear the Codes

After diagnosing and fixing the issue, you’ll want to clear the trouble codes and turn off the check engine light.

Repair the Problem

Replace faulty sensors, repair vacuum leaks, or fix wiring as needed. Use quality OEM or equivalent parts for longevity.

Clear the Codes

To reset the ECU and turn off the check engine light:

1. Disconnect the negative battery terminal.

2. Wait 10–15 minutes (this drains residual power from the ECU).

3. Reconnect the battery.

Alternatively, some models allow you to clear codes by turning the ignition on and off three times, but the battery method is more reliable.

Verify the Fix

Start the engine and monitor the check engine light. If it stays off, the problem is resolved. If it returns, recheck your work or look for additional codes.

Troubleshooting Common Issues

Even with the right steps, you might run into problems. Here’s how to handle them:

Check Engine Light Won’t Flash

If the light doesn’t flash when you short TE1 and E1:

– Double-check your jumper connections.

– Ensure the ignition is on (not just accessory).

– Test the battery voltage—low voltage can prevent communication.

Multiple Codes Appear

This often indicates a cascading issue. For example, a bad O2 sensor can cause a lean code. Fix the primary problem first, then clear codes and retest.

Light Comes Back On After Clearing

This means the issue wasn’t fully resolved. Re-run the diagnostic procedure and inspect related systems. Sometimes, a faulty sensor triggers secondary codes.

No Codes, But Light Is On

Rare, but possible. The light could be triggered by a loose gas cap (on later models) or a wiring issue. Inspect the light circuit and ECU connections.

Tips for Maintaining Your 94 Toyota Pickup in 2026

Keeping your truck in top shape goes beyond just checking the check engine light. Here are some proactive tips:

- Regular maintenance: Change oil, filters, and spark plugs on schedule.

- Inspect vacuum lines: Replace brittle or cracked hoses every few years.

- Use quality fuel: Avoid ethanol-heavy blends that can damage older fuel systems.

- Keep the ECU clean: Ensure the ECU box is sealed and free of moisture.

- Upgrade sensors: Consider modern replacements for O2 or ECT sensors with better accuracy.

Even in 2026, your 94 Toyota Pickup can be a reliable workhorse with proper care.

Conclusion

Learning how to check your 94 Toyota Pickup check engine light doesn’t have to be intimidating. With the OBD-I system, you can read trouble codes using just a paperclip and your eyes. By following this guide, you’ve gained the knowledge to diagnose common issues, perform basic repairs, and keep your truck running strong.

Remember: the check engine light is your truck’s way of saying, “Hey, something’s not right.” Ignoring it can lead to bigger problems down the road. But with the right tools and a little patience, you can tackle most issues yourself—saving money and gaining confidence in your mechanical skills.

Whether you’re restoring a classic or just keeping your daily driver on the road, understanding your vehicle’s diagnostics is a valuable skill. So the next time that light comes on, don’t panic. Grab your jumper wire, follow these steps, and take control of your truck’s health.